1.

2.

3.

4.

Wall-hung toilets are no different in functionality from floor-mounted structures, but there are significant differences in design and installation. The main difference is the need to install a suspended structure on the installation.

Advantages and disadvantages of wall-hung toilets with installation

To understand how to install a toilet installation, you need to understand the operating principles of wall-hung toilets, their design features and their qualities.Advantages of suspended structures:

- Significantly simplified cleaning. Wall-hung toilets were primarily created precisely to make cleaning the bathroom easier, if done correctly, since the presence of floor structures in it creates several hard-to-reach areas.

- Excellent aesthetic qualities. Mounted devices are characterized by good appearance and the ability to “fit” into the interior. It is simple to explain this phenomenon: there are no pipes in sight, all internal elements are covered with cladding, which can be processed in a style that best suits the interior of the bathroom. Only the toilet bowl and the flush button remain undisguised - and their right choice would be a good design decision.

- Visual advantage. In addition to good design qualities, suspended structures look better in the eyes of people from the point of view of rationality. As a rule, the human eye evaluates a room by its floor and ceiling. In this case, the floor is unloaded, and it seems that the bathroom is a little larger.

- Freeing up space. The design of wall-mounted toilets does free up a small amount of space, but this point is considered the most controversial: in practice, it turns out that the wall with the installed installation tends to the opposite side of the room, so the space savings will be insignificant.

Do-it-yourself toilet installation requires the following tools:

- Hammer with drill. Any structure requires fastening, and a hammer drill in this case will be the best solution. The main thing is that the diameter of the drill matches the diameter of the dowels that come with the toilet. In order to carry out the installation of toilet bowls efficiently, it is better to use anchor bolts that will connect the installation to the wall almost tightly.

- Construction level. The installation diagram of the toilet installation assumes compliance with horizontal and vertical levels. The level may be required for others construction work in the house.

- Roulette. When measuring distances between various structural elements, accuracy must be maintained. Roulette is an indispensable assistant in such situations.

- Pencil. Marking of mounting and technological holes is carried out using a pencil.

- Adjustable wrenches. They are used when connecting the water supply to the toilet and at the final stage - securing the toilet in its place.

- Silicone sealant. It is used where it is necessary to ensure the tightest possible connection, for example, at the junction of the toilet with the sewer.

Step-by-step installation of a toilet for installation

First you need to mark the frame. All measurements must be carried out in compliance with the levels. It is worth noting that when laying tiles on the floor, the toilet will be located below its surface (more details: " ").Now you need to drill out all the fasteners and mount the steel frame with screws or anchors.

The next step is to connect the tank to the water supply. To do this, you can use a flexible liner, but experts advise using pipes: rigid connections are much more reliable, but flexible ones will leak in the coming years, which will require breaking or dismantling the wall to fix.

The next step is covering the installation. As practice shows, the best material is double moisture resistant drywall. It is better to make a frame from metal profile, since the frame, due to its dimensions, is not very well suited for the role of support.

The drain button must be equipped with a cuff and a plug, which will protect the control element from clogging.

Now you can start installation finishing material. After completing this work, it makes sense to wait one and a half to two weeks until the tile or tile sits firmly in place.

Now you can adjust the dimensions of the drain and outlet pipes, after which the toilet is attached to the installation. The space between the wall and the toilet bowl must be covered with a gasket that will dampen the load. If the gasket was not included, you can use sealant.

The last step is connecting the drain key. When adjusting the rod of the control element, it is necessary to create the minimum possible free play. This completes the installation of the toilet.

There are a number of recommendations that will tell you how to choose the right plumbing fixtures and install them:- the choice of toilet can be made depending on personal preferences, and their quality can be determined visually when purchasing;

- the quality of the installation needs to be given much more attention, so here it is worth paying attention to the manufacturer (Western European companies are considered the best);

- creating a service hatch under the drain button can greatly facilitate repair work in the future;

- you need to lay the tiles symmetrically, and it is best to start from the flush button: this will allow you to position the cladding in the best possible way;

- It is advisable to use a system with dosed water discharge, which will save money and be much more convenient.

Conclusion

Installing a toilet installation is not the most difficult process if you follow all the described recommendations. As a last resort, you can always look at the photo, which shows in detail all the nuances associated with wall-hung toilets.

An innovative solution that allows you to create a comfortable and practical bathroom is the installation of an installation for plumbing fixtures. The design hides all pipes, components, couplings and other components in the wall, and the visible part is laconic and harmonious. How to install a toilet installation yourself is described in the article.

Advantages and disadvantages of using a toilet installation

The toilet installation system is a well-thought-out design that allows you to fix plumbing elements and hide their connection to the sewerage system. Thanks to such an installation system, it will be possible to hide the “technical contents” behind the false panel, while the toilet and flush button remain in sight.

The installation is used when installing floor or hanging plumbing fixtures. At the same time, the second option is gaining great popularity among consumers due to its undeniable advantages:

- freeing up additional space in the bathroom - especially important for small rooms;

- The plumbing does not come into contact with the floor, so cleaning becomes easier.

Installing a toilet with installation has a number of advantages compared to the traditional method of installing plumbing. The main advantages include:

- Attractive appearance. The installation is closed with finishing selected to match the style of the room. Exposed parts of plumbing may have unusual design solutions.

- Visual expansion of space - a less overloaded bathroom seems larger.

- Use of higher quality fittings. Since the components of the working mechanism are hidden and access to them is difficult, manufacturers try to minimize the risk of breakdown by installing high-quality float and key elements.

- Toilets designed for installation are equipped with a barrel with efficient water supply. Flushing occurs under high pressure, while water is used sparingly.

- Possibility of installation under various walls. The range of designs allows you to choose the model that is optimally suitable for the bathroom.

- Install the installation for wall hung toilet It’s quite possible to do it yourself. The main thing is to carefully study the instructions, understand the device and follow the installation technology.

- Quiet operation cistern.

- The height of the hanging models can be adjusted, choosing the optimal value for your own height.

Despite significant advantages, such a device also has some disadvantages:

- Installing a toilet with installation will cost more than purchasing conventional plumbing fixtures.

- To replace it, you will have to renovate the bathroom finishing.

- More complex installation technology.

Important! There is an opinion that in case of any breakdown it is necessary to dismantle the finishing and disassemble the structure. In fact, there is usually access to the internal parts underneath the removable drain key. Inspection hatches are provided for connection points and taps.

Types of wall-hung toilet installation designs

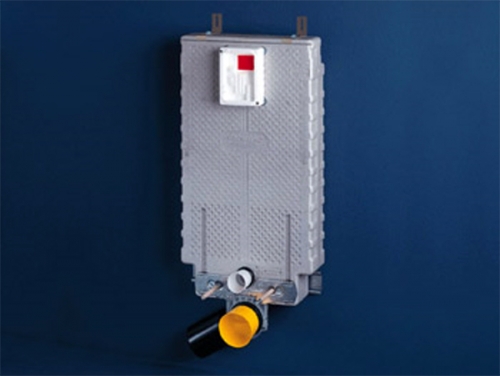

The construction market presents two types of installations for plumbing: block and frame systems.

Block module“recessed” into the load-bearing wall of the room. The design includes a plastic tank with fittings and fasteners for fixing the toilet. This option is designed for the installation of wall-mounted plumbing fixtures only. To build a block installation, you should cut a niche in the wall in advance. By choosing this model, you can save up to 15 cm of space.

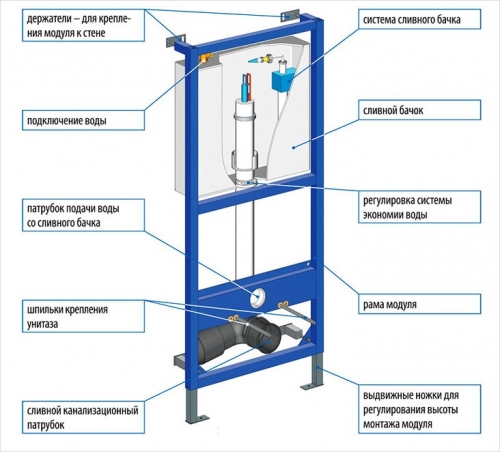

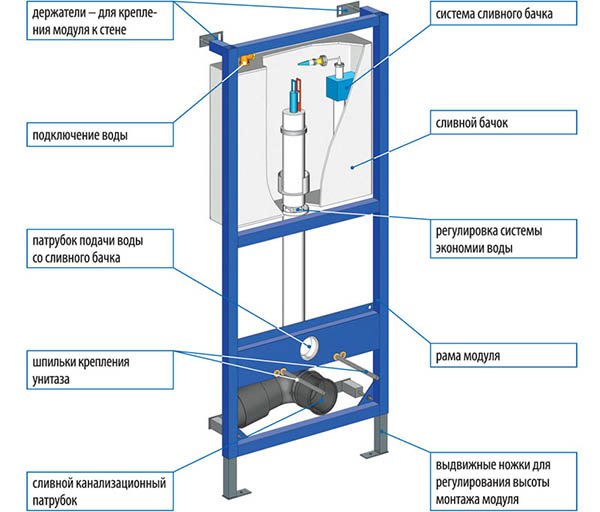

Frame installation consists of a solid steel frame and various fasteners. Standard frame configuration:

- steel body;

- holders for fixing the module to the wall;

- drain tank system;

- water supply hose;

- cistern;

- sewer pipe for draining;

- studs for attaching the toilet;

- water supply pipe;

- legs that regulate the installation height of the installation.

Distinctive features of frame modules:

- a large selection of installation options, both straight and angular;

- possibility of installation near any wall and interior partition;

- the cost of frame modules is higher than block structures.

When purchasing a toilet installation, it is important to consider the following parameters:

- Placement of plumbing fixtures and general arrangement in the bathroom.

- Compatibility of the selected installation system with the toilet. When purchasing a module, you need to check with the seller whether the system will fit a specific model of plumbing fixtures.

- The operating principle of the flush keys and the possibility of inspection through the viewing window.

- Installation system components. At the purchase stage, you should check the availability of all elements for self-installation. Sometimes, some parts are sold separately.

Installation of a wall-hung toilet with DIY installation. Frame design.

The optimal place for installing a toilet

A convenient location for the toilet is the least accessible place, away from the door. Usually, when placing installations, they are guided by the placement of risers. In some situations the module has to be moved:

- installation under a window requires the use of a low module up to 82 cm;

- double-sided installation - fastening of plumbing fixtures on both sides of the partition is carried out using a three-dimensional frame system that allows you to hang objects on both sides of the partition;

- installation of a toilet in the corner.

After choosing the installation location, you will need to make markings on the wall. First, you should mark the central axis of the model, then the contours of the frame location and the location of the installation on the wall/floor.

Advice. Before installing a toilet with your own hands, be sure to read the instructions and study the attached installation diagram.

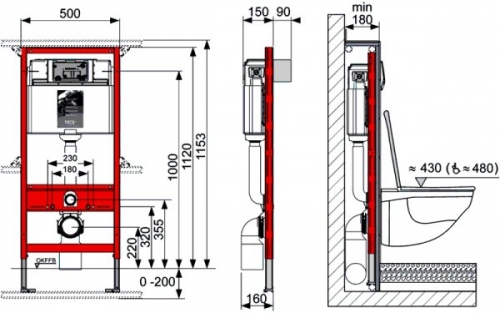

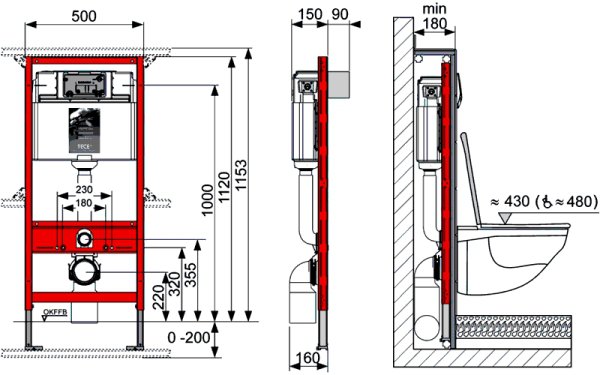

- toilet installation height from floor level - 43 cm;

- the optimal place to place the drain button is 1 m;

- the distance from the base of the wall to the surface of the steel frame of the module is 15 cm;

- the gap between the wall and the drain tank is at least 2 cm.

DIY toilet installation height: video

List of required tools

Installation of the installation module requires the following tools:

- a simple pencil or marker for making preliminary markings;

- construction/laser level for maintaining vertical and horizontal lines;

- roulette;

- tow for sealing seams;

- a hammer drill with a drill will be needed to create holes for fasteners;

- overhead open-end wrenches for connecting the pipeline and installing the toilet;

- silicone sealant for reliable connection of parts and sealing of joints.

Step-by-step instructions for installing a toilet installation yourself

Before you start installation work Sewerage and water supply pipes should be installed. The subsequent installation algorithm includes the following steps:

- Preparing the fastening system. Use a puncher to make holes according to the marks and insert dowels into them. The steel frame is fixed using 4 required fasteners.

- Installation of metal structures. First, the lower part is attached, then the evenness of the installation of the frame is checked and the height of the module is adjusted.

- Use anchor screws or special brackets to secure the metal frame to the wall. At this stage, it is important to check the strength of the installation - the structure should not wobble.

Connecting the sewerage and water supply system

To connect, you will need fixing plastic clamps to which the pipes of the sewerage system and the cistern are attached. It is advisable to carry out the work using reliable materials, for example, copper pipes. To save money, they can be replaced with polypropylene pipes.

After connecting and sealing the seams, a check is carried out - run the water and make sure that there are no leaks. Next, the pipes for installing the toilet are mounted, the drain pipe is fixed to the installation in a special recess.

Finishing work

Upon completion of work on supplying communications before installing the toilet, it is necessary to line the false panel. The frame is usually “sheathed” with plasterboard that is resistant to high humidity. Plaster sheets are attached with self-tapping screws to the frame or to a prepared frame of guide profiles.

Conceal the tank capacity with a safety strip. After this, decorate the plaster with tiles or other decorative material suitable for bathrooms.

Advice. It is advisable to start laying tiles on the installation with the drain button. It should be in the center of the tile or at the joint.

Securing the toilet

At the final stage, the toilet bowl is installed:

- There must be a backing between the toilet and the installation frame that protects the lining from friction with the plumbing body. If there is no suitable rubber backing, you can use silicone sealant.

- The nuts and bolts should not be over-tightened as this may cause cracks to appear on the toilet bowl. When fastening, a gasket must be placed between the elements.

- After installing the toilet, installation is carried out drain button. Insert the cables from the tank into the special holes on the button.

The frame module installation technology is identical for systems from most manufacturers. Do-it-yourself installation of a Grohe toilet is done in the manner described above.

Do-it-yourself toilet installation: video

Features of installing a block design installation

The installation of block modules is somewhat different from the installation technology of frame models. General procedure commissioning of a block installation:

- Use metal fasteners to secure the position of the knees.

- Cover the toilet outlet with silicone, install the plumbing fixtures in the right place and make a mark for future fasteners.

- Secure the drain tank with bolts.

- Attach the connecting cuff to the toilet.

- Close the drain button and check the system for leaks.

- Finish the wall and fix the position of the toilet.

Possible difficulties during the operation and installation of a DIY toilet installation

- If leaks appear in a floor-standing toilet, you need to check the tightness of the connections between the pipes and corrugations, and also improve the sealing of the joints.

- Tank leakage is the result of errors in the placement of sealing gaskets. To eliminate leaks, turn off the water supply taps, open inspection hatch, change the position of the gaskets and screw the tank panel back.

- If the slope of the drain is chosen incorrectly (less than 45°), then the water in the toilet will stagnate.

- Loosening of the toilet bowl is eliminated by tightening the bolts.

Do-it-yourself toilet installation repair

The main feature of plumbing repairs with installation is the dismantling of the decorative box. The most common breakdowns:

- tank leak;

- insufficient filling of the drain tank with water;

- constant filling of the tank;

- malfunction of the drain mechanism due to incorrect selection of disinfectant.

Installation dismantling sequence:

- Remove the flush plate by pressing it from the bottom.

- Remove frames. To begin, unscrew the screws and remove the pusher clamps.

- Disconnect the partitions by pressing the fastening clips.

- Shut off the water supply.

- Remove the fill valve and drain valve retainer.

- There is a drain valve inside the tank - it must be removed. After this, further repair work is carried out.

When the problems are resolved, assembly of the toilet installation is carried out in the reverse order.

Installation for a Grohe toilet: do-it-yourself repair. Video.

Installed toilets are real aristocrats in the world of plumbing. These are convenient and compact devices, usually distinguished by an excellent design and a price that is not at all sparing to its owner. In addition, installing a wall-hung toilet is a rather complex task and requires very careful execution.

And yet, the ranks of supporters of toilets with installation are steadily growing. Many home craftsmen, after studying the recommendations and instructions, successfully cope with installing this complex structure on their own.

It is only important to perform each stage of installation work correctly.

A wall-hung toilet is much more complex than a regular compact or monolith. The installation is called a durable metal frame. This frame is installed inside a wall niche and securely fixed to the wall and floor.

There is some space left between the wall-hung toilet bowl and the floor. It is easier to clean the bathroom in such conditions, since there is no toilet leg

The flat plastic tank is already attached to the frame. Then the necessary communications are brought to the niche, finishing is done and the toilet itself is hung.

The toilet remains outside, and the rest of the contents remain hidden in the wall. The flush button, which is usually located on the wall above the bowl, is also displayed on the wall. Even from this condensed description it can be understood that installing such a device is a labor-intensive process.

But still, the model with installation has many advantages:

- aesthetic appearance and attractive design - the bowl seems to float above the floor;

- compact dimensions, leaving wide space for placing the toilet in both small and large bathrooms;

- the absence of a leg makes cleaning the room much easier;

- The design of the installation is universal, it is possible to choose some elements to suit your taste and budget;

- Frame and tank breakdowns are extremely rare, and repairing or replacing the drain button is usually not difficult.

The bowls of wall-hung toilets vary markedly in configuration, design, shape, size, design, color and other characteristics, which leaves wide scope for choosing suitable plumbing fixtures

Among the disadvantages, the high price should be noted. Taking into account installation costs, the cost of such a toilet can be twice that of a standard floor-standing model.

However, manufacturers take into account the growing popularity of wall-hung plumbing fixtures, so relatively few inexpensive models. Another drawback is that the tank and frame, hidden in the wall, are not very accessible for repair.

In case of serious damage, you may have to turn the entire wall around and re-do it. finishing work in this area.

Materials and tools

To install a toilet with the installation of a built-in toilet, you must purchase the following items:

- installation frame with a plastic tank;

- wall hung toilet bowl;

- flush button;

- studs for attaching the toilet;

- a set of pipes for connecting the bowl to the tank, etc.

The installation is usually supplied complete with a flat plastic tank, as well as adapters, pipes, fasteners and a flush button. The kit usually includes a special material that protects the structure inside the wall from the effects of condensation, and also reduces the noise level from the operating tank.

When purchasing, you should carefully check the kit in order to immediately purchase the missing elements. The toilet bowl is also purchased separately. The dimensions and configuration of the installation, like other parts, are standardized, so they can be changed if desired.

For example, you can choose the new double flush button, which saves water.

The diagram clearly shows the installation device with a plastic flush cistern and the necessary connectors, which is intended for installing a wall-hung toilet

To complete the installation, you will also need a number of tools, first of all, a hammer drill and concrete drills that match the fasteners. You also need a building level, open-end spanners, a tape measure, a pencil for marking, a knife for cutting drywall, etc.

Installation procedure for a wall-hung toilet

Schematically, the procedure for installing a toilet with an installation can be represented in the form of a number of basic steps:

- Make a niche of a suitable size in the wall.

- Bring sewerage to the niche.

- Install the installation frame.

- Bring cold water supply pipes to the installation site.

- Connect the toilet cistern.

- Close the niche, install the flush button and finish.

- Hang the toilet, connecting it to the tank, as well as to the sewer.

You will also need a certain amount of drywall, both for installation and finishing work.

Each stage of work on installing a wall-mounted toilet requires close attention. The service life of the device, the number and nature of breakdowns largely depend on the quality of installation work.

The results of even minor errors made during the installation process may not become obvious immediately, but only during operation. Repairs can be very costly and time-consuming, so it is better to correctly install all the elements of this device right away than to redo it later.

The detailed installation procedure for a wall-hung toilet is presented in the following video:

Niche for installation

To create a niche and install the installation, only walls with the appropriate load-bearing capacity are suitable. The installation can withstand a weight of about 400 kg, and part of this load falls on the wall. Therefore, it would be unwise to install a wall-mounted toilet on a plasterboard wall; it might simply collapse.

So, to install the installation, you need to hollow out a niche in the wall with the following parameters:

- height - 1000 mm;

- width - 600 mm;

- depth - 150-200 mm.

Sometimes depth requirements are not easy to meet. In this case, a niche is made to the possible depth, and its deficiency is hidden with the help of drywall and finishing.

Thus, there is space for experimentation in the field of interior design. For example, you can make a built-in closet in the space between the ledge that appears and the wall, or hang open shelves there.

But the idea of simply placing a frame along the wall and then completely covering it with plasterboard does not make much sense. In this case, it is easier and cheaper to put a regular compact in the same place, which will take up the same amount of space or even less.

If the bathroom already has a niche for water supply and sewerage communications, it makes sense to install the installation in it

Residents upper floors apartment buildings sometimes they are installed in a niche of a fan riser. In this case, part of the fan riser is cut off and installed air valve where the attic outlet is located.

In some bathrooms, a niche for communications is provided by the design. It can also be used to mount the installation, but some modifications may be necessary, such as changing the position water pipes and move the sewer riser.

If a home craftsman has no experience in performing such operations, it is better to consult with a specialist or even entrust him with performing this part of the installation work.

Sewage supply

Before installing the frame, you must ensure that the sewer pipe is correctly connected to the installation site. You will need a pipe with a diameter of 100 mm. It should be laid as close to the floor as possible, and it is imperative to maintain the correct slope.

The connection point should be 250 mm from the center of the wall niche. An oblique bend with an angle of 45 degrees is put on the horizontal part of the pipe. After completing these operations, you can begin installing the installation.

Installation of frame with tank

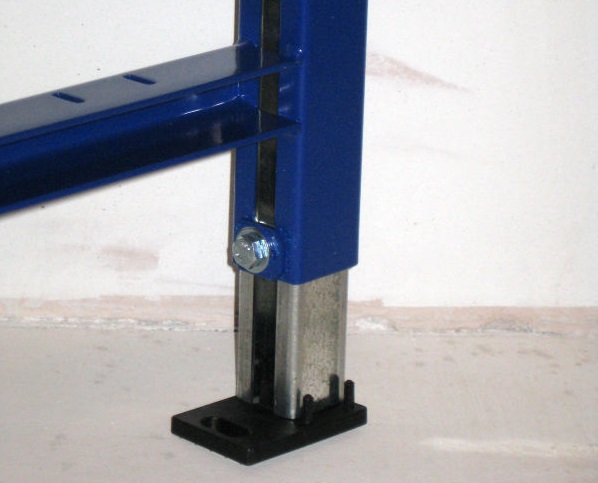

There are four points for mounting the toilet installation. In two places the legs of the frame are attached to the floor, and in two more places the frame is secured to the wall using brackets. In this case, you should definitely use a building level so that the structure stands perfectly level both vertically and horizontally.

If the installation is installed even with a slight misalignment, interruptions may occur in the operation of the internal mechanism, which will lead to rapid failure of the structure. To level the frame vertically, use adjustable legs.

The horizontal position is set using wall fasteners, the position of which can also be changed as needed. Once the position of the installation is precisely set and fixed, you can screw it to the wall. To give the frame greater stability, the legs can be additionally cemented.

A layer of screed 20 cm high will be sufficient, but this measure is not mandatory.

The height of the frame legs for a wall-hung toilet can be adjusted. This allows the structure to be aligned horizontally and strictly level.

At the bottom of the installation there are several holes intended for further installation of the hanging bowl. The distance between the floor and these holes should be approximately 300-400 mm so that the toilet bowl can be hung high enough from the floor. Special pins should be installed in these holes.

They are inserted all the way into the wall and secured with special nuts. The studs are designed for later hanging the toilet.

The studs, which are intended for hanging the toilet bowl, must be inserted into the corresponding holes on the frame and secured to the wall

Connecting communications

You should start by connecting the sewer system. Typically, the installation is equipped with a special black outlet designed for this connection. It should be adjusted to the sewer pipe. The second side of the outlet is secured to the installation with special clips.

Connection to the water supply is made on the right or left side of the installation. The water pipe is connected using a threaded connection already installed in the structure.

To supply water to the tank, you can also use ordinary flexible hoses. This is an easy-to-install and inexpensive option, but the hoses have a shorter lifespan than pipes, so you have to consider the need for complex repairs to replace them.

At this stage, it is necessary to check the reliability of the connection of the tank to the water supply system. To do this, you need to open the water supply tap, which is located inside the tank, and fill the container. All connections are then checked for leaks and repaired if necessary. There is no need to drain the water.

The sewer connection can be checked as follows: place a bowl on the studs and perform a test flush without securing the structure.

After this, the bowl should be removed from the mount, checked for the presence or absence of leaks, and then continue installation.

Finishing work

If the installation is installed correctly and the tank does not leak, you need to sew up the niche with a sheet of plasterboard and perform finishing work. It is recommended to take a double sheet of special moisture-resistant drywall. Regular drywall will soon be damaged due to contact with condensation.

To correctly cut all the mounting holes in the sheet and not spoil the material, use a cutting template. Typically, such a template is supplied with the installation.

When the installation is installed and all necessary communications are connected, the niche is sewn up with a sheet of moisture-resistant plasterboard, on which finishing work is then carried out.

In the bathroom, the walls are most often tiled ceramic tiles. TO further work Installation of a wall-hung toilet can only begin after this stage is completed.

It would not be a mistake to even completely complete the renovation of the bathroom, and only then continue with the installation of a wall-hung toilet with installation.

Installation of a wall hung toilet

This stage can be called the simplest, since the bulk of the work has already been completed. But first it is recommended to wait until the layer of tile adhesive has completely dried. Install the toilet bowl as follows:

- Adjust the dimensions of the drain pipe, which should protrude 50 mm beyond the wall.

- The pipe intended for sewer drainage is cut in the same way.

- Install the pipes in their designated places.

- A special large gasket is placed on the previously installed studs and pipes; its configuration is similar to a truncated pyramid.

- Place the toilet bowl on the studs, securely connecting it to the pipes.

- Install plastic inserts and rubber gaskets.

- Place and tighten the mounting nuts.

- Cut off the protruding part of the rubber gasket.

Hanging the toilet with the installation, connecting it to the sewer and cistern, as well as installing the flush button is carried out after finishing the finishing work

After this, you can check the operation of the sewer system by flushing water from the tank into the toilet bowl. To adjust the height of the toilet bowl above the floor, you can change the position of the retractable pins and studs designed to hang the bowl. In this case, they usually focus on the height of the visitor.

The universal height is considered to be a distance of 40 cm from the edge of the bowl to the floor level.

Installation of the flush button

All that remains is to install the flush button. It can be pneumatic or mechanical. This is not a complicated operation, since all connections are already provided on the installation and should already be connected to the corresponding hole on the wall.

To install a mechanical button, you will need to install special pins and then adjust their position. The pneumatic model only needs to be connected to the tedious tubes on the installation, and it will be ready for use.

Wall-hung toilets have firmly entered the lives of citizens due to their compactness and interesting looking. Unlike ordinary specimens, they are attached not to the floor, but to the wall. With this type of mounting, the tank is hidden, and the connection to the sewer and the drainage system are hidden in the toilet installation itself. Thus, the wall-mounted toilet design looks aesthetically pleasing and modern. In addition, it is very reliable and can support weights of up to 400 kg.

Design of a hanging tank with installation

Before considering how to install a wall-hung toilet with an installation, you should select it (about the rules), and also determine the main components of the fastening mechanism.The service life of the plumbing fixture will depend on the quality of the chosen design. In general, a wall-hung toilet consists of the following parts:

- steel frame;

- toilet bowls;

- tank;

- exhaust pipe;

- sound insulation;

- flush keys;

- fasteners.

The durable frame is attached both to the floor and to the wall with special studs. It has rods for adjusting the height of the product. The drainage container of the structure is made of plastic, coated with a condensate coating. On the front of the tank there is a special cutout in which the drainage system is installed.

Choosing a location and installation diagram for the toilet

A good location for the device is considered to be a low-traffic area away from the door, so you can choose the far wall. But it is worth considering that all communications should be close to the toilet so that they do not have to be routed across the entire room.As preparatory work The location of the future structure is marked. On the floor and wall on which the toilet will be mounted, lines indicate the location of the frame and its connections to the surface. Marking begins from the place where the central axis of the device will be located. Finally, you need to mark the mounting points for the installation frame on the wall and floor.

Before carrying out installation work, it is worth studying a typical installation diagram for a toilet installation.

The main parameters for fastening the structure are:

- toilet height – average size is 430 mm;

- the drain button should be approximately 1 meter above the facing floor;

- the minimum distance from the wall to the outer surface of the installation frame is 150 mm;

- A gap of 20 mm must be maintained between the cistern and the wall.

Installation Tools

To complete all the installation work for the toilet, you need to have the following tools:- laser or regular level;

- marker or construction pencil;

- hammer drill, concrete drill;

- measuring tape;

- overhead open-end wrenches.

Installation instructions

Before carrying out installation work, you first need to install a sewer pipe with a diameter of 110 mm, and then water pipes.Here are the step-by-step steps on how to install a toilet installation:

- Preparing the mount . Holes are made in the wall at previously marked places using a hammer drill. Dowels are inserted into them. Fastenings can be made both diagonally and vertically. The installation frame has 4 mandatory fastenings: 2 on the wall and 2 on the floor.

- Installation of a metal structure . Produced by fastening starting from the floor. Then the position of the frame is checked by level and adjusted using the sliding devices provided on it.

- Attaching the frame to the wall . This is done using special brackets, and in some cases you can use self-tapping screws or anchor screws.

After installing the frame, it is necessary to check the reliability of the structure, to prevent its vibrations to the sides, otherwise under heavy loads it may tilt. After these steps, do-it-yourself frame installation is complete.

Connecting water pipes and sewerage

This is the most important part of installing a new toilet, because if a leak appears in one of the pipes, the entire structure and the lining of the wall on which the wall-hung toilet is located will have to be dismantled.For such a toilet, only time-tested materials are used - it is better to choose pipes made of copper, and if material possibilities do not allow, then they should be replaced with polypropylene analogues. The seams are sealed with tow. If it is necessary to use flexible hoses, they must be made of stainless steel.

The last step is to check all connections, which can be done by running water. Confirmation correct installation installations for the toilet - smooth operation of the entire system without leaks.

After testing the water, you need to install the pipes to which the toilet will be connected. The frame has a crossbar to which a special plate with a diametrical recess is attached. Thanks to it, the drain pipe is fixed to the installation. All steps for connecting pipes are carried out according to the instructions.

Facing the false panel

It is carried out after all plumbing work before installing the toilet. Since the structure is located in a kind of niche, it does not matter what material it will be sheathed with. Typically, plasterboard is used for these purposes, and it is moisture resistant.Using this material, you can easily close the front wall with the frame placed on it. Drywall can be attached to self-tapping screws, or to a pre-made frame made of guide profiles.

After lining the front of the tank, you need to insert the restrictive cuff, and then close the tank with a safety lid.

Any tile or other facing material can be laid on drywall.

Securing a wall-hung toilet

Do-it-yourself toilet installation must be carried out taking into account the following rule: a rubber backing must be laid between the tiles and the toilet, which will protect not only the facing material from cracking, but also the bidet itself. If for some reason the factory backing is lost, it can be replaced with a thick layer of sealant. When it hardens, it will act as a shock-absorbing cushion.Tightening the nuts and bolts on the toilet is also fraught with cracks and the subsequent formation of chips, therefore, when fastening them, it is necessary to use softening substrates.

The final stage of installation work is the installation of the drain button. How to install it correctly is described in the installation instructions. Before necessary work you need to open the water and insert the cables from the tank into the holes located on the button.

The installation process ends with checking the functionality of the structure, which then puts it into operation.

How to install a toilet installation? (video)

You can clearly see the installation of the toilet installation in the video below:A wall-hung toilet is aesthetically pleasing, stylish and reliable. All work on its installation can be done with your own hands, taking into account the tips given above and the installation instructions.

Alexey Shamborsky, 09/25/2014

Space saving and aesthetic features are the main advantages of a wall-hung toilet, therefore, choosing this option, its owner will certainly not go wrong. If there are no special issues with the installation of the toilet, then its wall-hung “brother” will require sleight of hand due to the presence of an additional link in the bathroom - the installation. Do-it-yourself toilet installation is not difficult if you have all the necessary construction tools and carry out the work step by step.

The uninterrupted functioning of the plumbing product depends on the installation sequence of the toilet installation. First of all, its installation itself is carried out, then the connection of the sewerage system, camouflage of visible elements and finishing are carried out. For clarity, below are photos and videos of installing the installation under the toilet, which will make it much easier to perceive the information.

Preparatory stage

First of all, you need to purchase an installation system along with the toilet. Unlike bidets, today there is a wide selection of bidets on the market. By their principle, they are all a hidden mounting frame. But here, as they say, to each his own.

The tools you will need are a hammer drill or a drill, a concrete drill with a diameter equal to the hole of the fasteners, wrenches, building level, pencil and tape measure.

When all the necessary construction equipment is at hand, we begin marking and preparing the fastener system. It is important to measure the distance from the installation system to the wall surface and mark the location of the cistern. It would be correct to install it at a height of 100 cm from the floor.

Do not forget about fastening the installation itself: it is necessary to mark points for fastening elements on the surface of the wall and floor. In this case, fasteners should be given special attention. Using a hammer drill, holes are drilled along the previously made marks, where anchors with dowels are inserted.

Installation of wall-hung toilets

The toilet installation diagram has a clear sequence:

- a frame is installed in a pre-prepared place, which is fixed with special adjusting nuts and screws;

- the installation body is adjusted horizontally and vertically;

- The horizontal level is set by adjusting the design of the legs, and the vertical level by adjusting the anchor thread.

After installing the installation under the toilet, you need to connect the toilet to the sewer pipe. It was important to pre-install a drain pipe with a diameter of 110 mm and connect the water supply.

Regarding the water supply to the tank, experts recommend using a rigid pipe instead of a flexible pipe. Pipes from the cistern and sewer pipe are attached to fixing plastic clamps.

Schematic video from Geberit: