Today the market is overflowing with a wide variety of construction and finishing materials. Until recently, for insulation wooden houses used materials such as cotton wool, roofing felt, sawdust. Currently, polymer insulation materials are becoming increasingly popular. These include mineral wool, polystyrene foam, polystyrene foam, ecowool, polyurethane foam, penoplex and others.

According to experts, approximately 20-30% of the heat in a wooden house is lost due to improperly organized thermal insulation. Insulate wooden house needed in all areas, from the foundation to the roof. Internal insulation of floors and walls is of great importance. Thermal insulation provides reliable protection residents wooden house from the penetration of cold air, the formation of condensation, which can contribute to the formation of mold and deterioration of sanitary and hygienic living conditions. Let us consider in more detail how to organize the insulation of a wooden house from the inside, the main types of insulation, their pros and cons.

Characteristics of insulation

Before carrying out internal insulation of a wooden house, it is necessary to choose the right insulation. You can insulate a wooden house from the inside using various materials.

So, one of the most popular is mineral basalt wool. It has low thermal conductivity, so it does not allow cold air masses to pass through. Fire-resistant, it can also withstand the effects of various chemical agents without changing its properties. It has a good noise insulation effect. This is an environmentally friendly product. Cotton wool is easy to install, has low weight and cost. Available in the form of rolls and slabs. Excellent for insulating walls and ceilings.

You can also insulate a wooden house from the inside using glass wool. This material is elastic and very durable. Glass wool is not subject to shrinkage over time and withstands vibration very well. This is a durable material. Of great importance is the fact that it does not absorb water and is capable of transmitting steam. It is more suitable for cladding facades and wooden structures.

If the internal insulation of a wooden house is carried out with polystyrene foam, then you need to keep in mind that it is a fire hazard. Polystyrene foam is lightweight and not resistant to organic solvents. You can insulate concrete floors, walls, and roofs with polystyrene foam. In contrast, expanded polystyrene is more durable. It is produced in the form of slabs.

It is important to know that polystyrene foam is not suitable for insulating wooden houses, since it is not capable of allowing air to pass through, while a wooden house constantly needs ventilation.

One of the best options is polyurethane foam. Insulating a wooden house from the inside with it gives a good effect. It is used in the form of liquid foam, which quickly hardens. It perfectly protects against noise and vibration. Fireproof and environmentally friendly.

Basic rules for insulating a wooden house from the inside

Internal insulation of a wooden house is not always the best option. This primarily concerns the insulation of walls. The best option is to do it outside. Internal insulation creates good conditions for the formation of condensation between the insulation layer and the structure. As a result, humidity increases and thermal insulation properties deteriorate, which contributes to the formation of mold. This is of great importance in cold period years when the water begins to freeze and gradually destroy the structure. In addition, insulating a wooden house inside reduces the usable area of the premises, since a thermal insulation layer of 10-15 cm is often required.

Before you insulate a wooden house from the inside, you need to know that almost all types of materials emit harmful chemicals into the indoor air, albeit in small quantities. Some of them, for example, polystyrene foam, are flammable, which is especially dangerous for a wooden house. Despite all the disadvantages of this method, internal insulation is cheaper than external insulation.

Insulation of the floor of a wooden house

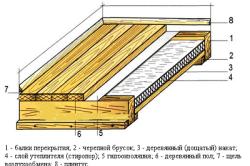

Insulation of a wooden house includes insulation of the floor. There are several ways to do this. The double floor system is widely used. It consists in the fact that first the rough layer is laid, and then the finishing layer, and insulation is done between them. First, the subfloor is laid. To do this, a beam with a cross section of 50 x 50 mm is attached to the logs using screws. Boards will be nailed onto it. The boards should be 25 mm thick and 150 mm wide. You can take any boards, it is important that there are no gaps between them subsequently. If hygroscopic materials are used as insulation, then it is advisable to make waterproofing in the form of laying polyethylene film. A special vapor-permeable membrane is placed on it. The logs should not reach the walls by a few centimeters. This gap is filled with basalt wool.

The next stage is laying the finished floor. To do this, you need to have well-hewn, milled boards 10-15 cm wide, 3-4 cm thick with a tongue-and-groove joint. The finishing floor spreads at a distance of 3-5 cm above the rough floor. This is necessary for air circulation. After this, the plinths are installed, they are joined at right angles along the length. They are attached to the wall with nails. To ensure air exchange, small holes with a diameter of about 0.5 cm are made in each corner of the finished floor. They are covered with a grid.

Other ways to insulate a wooden floor

You can insulate a house from the inside using various methods. The simplest and most economical single floor insulation system. In this case, there is no need to construct a rough and finishing floor. In this case, insulation will be carried out directly on the foundation or on the trim. At the first stage, the base of the floor is covered with a loose mixture based on sand and gravel. The thickness of the layer is about 2 cm. Rolls of roofing material are laid on it, and again a sand-gravel mixture is placed on them. These materials will provide good waterproofing. Then a plastic film is attached to the base of the floor using a stapler.

The next step is laying insulation. For these purposes, it is recommended to use penoplex. It is laid in the form of slabs in one layer. Fiberboards are placed on it in 2 layers. After this, the finished floor is installed. You can also insulate the floor using electric cable. Today, electrically heated floors are quite common. But at the same time, you need to remember that such insulation is not fire safe, especially for a wooden house. Therefore, we will not consider it in detail.

Insulating the walls of a wooden house from the inside

To properly insulate a house, do not forget about the walls. After all, they are the main ones load-bearing structures. Despite the fact that polystyrene foam is not fire safe, it is excellent for thermal insulation of the walls of a wooden house from the inside. The first stage is preparatory. You will need to clean the surfaces of debris, dirt, foreign objects, and remove old nails and screws. The holes left in the wall are filled with alabaster. Next, level the surface. To do this, it is advisable to use plaster or putty.

In addition, all baseboards and borders are removed. After this, priming is carried out using an acrylic solution. It prevents the formation of fungal mold on the wall. The primer is poured into a small container and applied with a roller in an even layer. After about a day, you can proceed directly to the insulation itself. The foam is laid from the far lower corner. A hole 5 cm deep is drilled in each sheet, an umbrella with a cap is inserted into it, but so that it does not extend beyond the foam. You can hammer a dowel into the umbrella. Each sheet is fixed in this way at 5 points. The connection of the sheets is made tight, without gaps. You can use a knife or hacksaw for sawing. The seams between the sheets can be sealed with polyurethane foam. For large seams, you can use pieces of insulation. A reinforcing mesh is laid and secured onto the foam layer using an adhesive solution. The mesh should be fine-mesh. The final stage is cleaning the surface with an emery tool.

List of tools and materials

Insulating a house will require a whole set of tools and materials. It includes: foam plastic, mineral wool, penoplex, sandpaper, screwdriver, drill, brush, sand and gravel mixture, reinforced mesh, tape, stapler, spatula, primer, putty, plastic film, vapor-permeable membrane, buckets, shovel, nails , dowels, screws, alabaster, acrylic mortar, roller or brush, wooden boards, beams, hammer, roofing felt, polyurethane foam. Thus, one of the most important stages is insulating the floor of a wooden house. This can dramatically reduce heat loss in the home and normalize the temperature.

Wood is the most environmentally friendly pure material. If you decide to build a wooden house, then over time the question of insulating it will arise. More often this procedure is carried out outside, but sometimes this is not possible. If you decide to insulate a wooden house from the inside, you need to pay attention to some factors. If the work is carried out incorrectly, the microclimate can be disrupted, creating a “greenhouse effect” inside. Insulating the inside of a house leads to a reduction in the area of the room. Consider these factors before starting insulation work.

Choosing insulation material

Manufacturers offer large number materials for insulation. Let's talk about their advantages and disadvantages.

Mineral wool is an ideal material for any surface. Its disadvantage is its sensitivity to moisture. Therefore, it is necessary to take care of an additional layer of waterproofing. Mineral wool is a non-flammable and environmentally friendly material.

Penoplex not exposed to moisture. He doesn't change technical characteristics with long-term use. To install this material you do not need to have special skills. Penoplex has good heat-insulating properties.

Often used for insulation polystyrene foam. Its availability is due to its low price. But the main disadvantages are their short service life and flammability.

With the help of extruded polystyrene foam(another name for extruded polystyrene foam) can effectively insulate both walls, ceilings and floors. An undeniable advantage is the almost complete absence of moisture absorption.

When choosing a material, the first thing you need to pay attention to is the purpose and scope of work. To ensure that the insulation process does not stop halfway, do not forget about the budget.

Preparatory work

The work preceding the main work consists of cleaning the surface and sealing cracks.

The first thing you need to do is remove the dust that has accumulated on the surface. Trees are easy prey for insects. To prevent them from damaging the surface, we treat it with an insect repellent. Another problem with wooden structures is their susceptibility to rot. To ensure that you enjoy your home for many years to come, you must also apply an anti-rot solution.

Over time, due to shrinkage, gaps may appear between the beams. Some of them are not visible, but this does not mean that heat does not escape into them. These cracks need to be sealed. Most often, jute fiber is used for caulking. If the gap is large, then it is more advisable to use tape tow. It is rolled into a roll and pushed through with a chisel. The gap must be filled until the material hangs out.

Vapor barrier of walls from the inside

After the insulation work is completed, the microclimate in the house may change. In order to optimize the humidity in the room, forced ventilation is used. Another point to pay attention to is that moisture should not come into contact with the timber. For this, a vapor barrier layer is used.

For these purposes, polyethylene film or penofol is used. The foil film is fixed to the entire surface, with the shiny side facing the wood. This will prevent the wood from getting wet. This way we will avoid rotting. The joints of the vapor barrier can be sealed with tape.

Insulation and ventilation

We described the types of insulation used in a wooden house above. Most often used for these purposes mineral wool. It is ideal for wooden houses, as it is an environmentally friendly and non-flammable material. Let's dwell on the technology of insulation with this mineral wool.

In order to secure the material to the wall, you first need to make a frame. It can be made of either wooden slats or metal profile. The latter option is easy to install and has additional elements that help achieve the correct geometric shapes. The metal frame will help not only to insulate, but also to level the surface. Using a level, mark a line for attaching the guides. We install them on the floor and ceiling. We secure the structure with dowels. The profiles should be placed at a distance of no more than 50 cm from each other. We fix it with metal screws.

When the preparation of the frame is completed, we proceed to fixing the insulation. Mineral wool is easily installed on the sheathing. The main thing is to pay attention so that no gaps arise. Mineral wool is well suited for insulating wooden houses. But this is very capricious material. To prevent moisture from damaging the insulation layer, it is necessary to secure a waterproofing layer on top.

It is convenient to place not only insulation on a metal frame. It also serves to secure the finish.

After you have completed the insulation work, the microclimate of the house will become more humid. To do this, it is necessary to make forced ventilation. When using external hoods, heat will escape from the house. In this case, an axial fan of medium power is used. Twenty minutes of room ventilation will save you from problems with the formation of excess condensation.

Thus, if you want to insulate a wooden house with your own hands, you should not neglect waterproofing materials. This will prevent the insulation from getting wet. Choose a thermal insulating material depending on its characteristics. Do not save money and do not neglect the advice and laws of physics.

Video - insulating a wooden house from the inside

Materials for home insulation - varieties

In order for insulation of a wooden house from the inside with your own hands to be effective and correct, first of all you should understand the process itself, and only after that make a decision.

Previously, insulation of walls inside a wooden house was not the best important issue, since to preserve heat in the house they simply increased their thickness. But the emergence of a large number of thermal insulation materials on modern market, allows you to look at the solution to the problem from a different perspective. Since increasing the thickness of the wall is quite complex and expensive, it is necessary to study the pros and cons of modern insulation materials and technologies.

Insulation of the walls of a wooden house from the inside - beautiful and high quality

In principle, wood has good thermal insulation properties. Due to its natural structure, this building material It retains heat perfectly, and also, due to its ability to “breathe,” creates an excellent favorable microclimate in the house.

But there are still heat losses, largely due to the problem of connecting logs, gaps appear in corners, crosscuts, doors and windows. Additional gaps may arise in the event of natural shrinkage of the building under the influence of various natural factors. Therefore, the issue of the tightness of such dwellings is always relevant, and as a result, insulation interior walls a wooden house is simply necessary.

How to avoid mistakes

Obviously, insulating walls in a wooden house from the inside is quite simple from a technical point of view, but this option is not very widespread. There are several reasons for this, and reducing living space is far from the worst thing.

Therefore, to find out whether it is possible to insulate a wooden house from the inside, and most importantly how to avoid mistakes, you should pay attention to several factors:

- Insulated walls do not warm up well from the inside.

- Dew point. To better understand what it is, you should watch the video in this article.

When temperatures change, the dew point can shift into the thermal insulation layer, which will lead to the formation of condensation, dampness and deterioration of the insulation itself. Also, the formation of fungus and mold, which is destructive for a wooden house, is possible.

This problem will be partially solved by the presence of a vapor barrier layer. But in this case, you need to take care of installing effective forced ventilation in the room so that you don’t feel like you’re living in a plastic bag.

Also, a solution to the problem of shifting the dew point is to increase the thickness of the thermal insulation layer, but this is extremely unprofitable for the resident, since the living space is significantly reduced.

Before you start

Before you start insulating the walls of a wooden house inside, you need to determine:

- What type of wood was used in the construction of the building?. Because different types wood has different properties and characteristics, which means there will be different costs for insulation.

- Causes of heat loss, namely cracks, cracks in logs, defects in insulation padding.

Having identified the shortcomings and determined the range of upcoming work, we move on to insulating the walls.

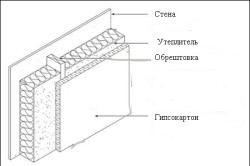

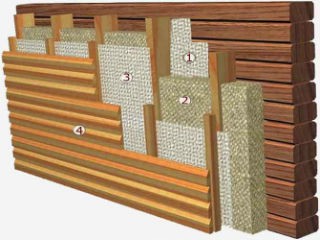

The general scheme for insulating a wooden house is shown in the photo:

- Vapor barrier system;

- Thermal insulation;

- Waterproofing;

- Cladding with clapboard.

You need to know that it is best to insulate walls in the spring or summer season.

If the house was built not long ago, then insulation from the inside of a wooden house is carried out only after its shrinkage, that is, a year after construction was completed, in order to prevent the emergence of new cracks through which moisture can enter and spoil the material.

All work on insulation from the inside is conditionally divided into the following stages:

- Surface preparation.

- Caulking cracks.

- Creation of a vapor barrier.

- Installation of sheathing.

- Laying insulation.

- Creation of an effective ventilation system.

- Finishing work.

Material selection

Currently, do-it-yourself insulation of walls from the inside of a wooden house is usually done using synthetic insulation. The main indicators for such materials are resistance to ignition, as well as high thermal insulation characteristics.

Ecowool

Currently, the so-called is gaining increasing popularity.

This is explained by the very structure of this material and the properties it exhibits:

- Moisture inside the room can pass between the fibers almost unhindered. But at the same time, the interfiber space itself remains dry, which means that condensation of excess water vapor does not form on the wall.

- Also, thanks to this property and the presence of mineral antiseptics, protection is provided against mold and fungal infections on the walls of the room.

- The ability of the material to “breathe”.

Thanks to these properties, it is used to ensure heat retention both outside and inside.

The material is sprayed with a complete thermal insulation layer, which is tightly adjacent to the log or timber. Thanks to its structure, ecowool fills all existing voids and cracks, thereby preventing possible heat loss.

Professionals apply ecowool using special devices, but if you carry out the internal insulation of a wooden house yourself, we recommend watching a video that provides instructions on how to properly apply this material.

Basalt wool, glass wool

No less common thermal insulation material is polystyrene foam (foam) boards.

Positive aspects of using polystyrene foam:

- Elasticity;

- Ease;

- High thermal insulation characteristics;

- High sound insulation properties;

Thanks to these qualities, it is possible to use fairly thin slabs, which reduces the reduction in usable area to a minimum.

Also important is the gradual improvement of foam insulation technologies, which significantly affects its characteristics.

To insulate wooden walls, the so-called intra-wall insulation method is sometimes used. This method involves the use of deformation-resistant insulation. These include flax wool, flax and hemp tow.

The method is used only when the building is just beginning to be built. Insulation consists of laying material into the interior space, which eliminates the appearance of cracks and walls.

In conclusion

Of course, in this article we only talked about part of the technologies used. But the types of thermal insulation materials we have considered are the most popular due to their durability and practicality.

This article will be useful to you if you refer to the section on insulating a loggia. Let's hope that our recommendations for insulating the walls of a wooden house from the inside will help you and make your home warm and cozy.

We will not discuss the insulation of frame wooden houses here - this is a completely separate conversation, there is a different technology and we will talk about them in other articles.

Why it is not advisable to insulate walls from the inside, and what consequences may arise, I have already described in one of the previous articles.

Here we will talk exclusively about the features of internal insulation related to wooden houses.

In principle, there are not many features; basically, it is necessary to adhere to the basic rules of insulating walls from the inside, the main one of which says that no insulation of walls from the inside can replace high-quality insulation of the house from the outside. But if there are no options, then you need to adhere to a certain technology.

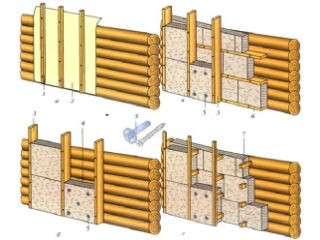

Preparing the wall of a wooden house for insulation

This stage is very important, since after insulation, access to the beam from the inside will be very limited, and in order to fix anything it will be necessary to completely dismantle the insulation.

And so, first of all, it is necessary to clean the walls from the inside from dust, dirt, various peelings, etc.

Then seal the cracks and holes that appear.

Deal with electrical wiring if you have wires running along the walls. If the house is old, it would be better to check all the electrical wiring and repair it if necessary; if it is new, then carry out the installation, not forgetting about electrical safety in wooden houses.

Vapor barrier for insulation

Before installing the insulation, it is necessary to prepare a vapor barrier. It is necessary to protect the insulation from moisture on the walls, which will be inevitable after insulating the wooden walls of the house from the inside. In turn, the more moisture inside the insulation, the less useful it will be.

The vapor barrier film also has a negative effect - creating a thermos in the room. The walls practically stop “breathing”, and humidity, as a rule, rises. Only good ventilation can save you from this. Without ventilation, insulating walls from the inside is not worth starting, because over time you will begin to get the feeling that you are living in a plastic bag, and the walls will begin to sweat and get wet, and subsequently fungus and mold will appear, which will have a very detrimental effect on wooden walls and on the health of people living in the house.

Vapor barrier can be made with a special membrane film, which will do its job much better and more correctly, but it is much more expensive.

Installation of insulation on a cotton basis

As a rule, installation of mineral wool is carried out using lathing, since this is the most suitable option due to the characteristics of this type of insulation.

As a rule, installation of mineral wool is carried out using lathing, since this is the most suitable option due to the characteristics of this type of insulation.

A wooden sheathing is installed on the wall, on top of the vapor barrier (it is not advisable to use metal, since metal has a very high thermal conductivity).

Then insulation is laid between the slats. The most commonly used material for interior wall cladding is plasterboard. It is usually screwed directly to the sheathing.

Installation of polystyrene foam insulation

Polystyrene foam is the cheapest and most practical insulation material available today. Expanded polystyrene is used very often as external insulation, mainly due to its low cost and low thermal conductivity.

But despite this, it is least suitable for insulating a house from the inside.

There are several reasons for this:

- release of toxic substances (the higher the temperature, the more)

- airtight

- Over time, rodents may appear in it

Installation of Ecowool insulation

The characteristics of ecowool are much more favorable for insulating the walls of a wooden house from the inside:

- breathable material

- there is some kind of protection against fungi and mold

- Due to the passage of air through itself, it prevents the walls from storing increased moisture.

Common mistakes when insulating wooden walls from the inside with your own hands

- Many people believe that the more insulation when insulating from the inside, the better. I assure you that this is a myth. If there is too much insulation on the inside of the walls, the dew point can move into the insulation itself, and if it is on a cotton base, its thermal insulation will decrease significantly, and the insulation itself will not last long in damp conditions.

- Some people insulate the wooden wall of a house on both sides, and this will have a very detrimental effect on the wall itself. The reason for this is the vapor barrier of the insulation, which will not allow the wall to dry out, and over time, fungi, mold and rot will appear there, which will destroy your wooden structure much faster than you think.

If you have the opportunity to insulate a wooden house from the outside, then insulate it without hesitation; insulating walls from the inside is fundamentally wrong and resorting to this type of insulation is necessary only in extreme cases, when there are no other options.

- It is advisable to insulate walls, both from the outside and from the inside, in the warm season, when the wall is as dry as possible.

- If you have any cladding on the outside of your home, you need to make sure that between the cladding and wooden wall There are vents that will allow your wall to dry out at least somehow.

- Before installing insulation from the inside, carefully treat the wooden walls of the house, because after insulation the wall will have a microclimate of increased danger to the wood and excess impregnation will not harm.

- If you are planning to sheathe the inside of the walls with plasterboard, then when installing the sheathing, take into account the dimensions so that you do not have to construct additional fastenings for the plasterboard.

- Do not use polystyrene foam for insulation from the inside; do not be fooled by its cheapness and excellent qualities as an insulation material. For interior work he doesn't fit.

Insulating a wooden house from the inside using, among other things, is a necessary set of measures in order to increase the level of comfort when living in it.

When insulating the roof, ceiling, attic and floor, in most cases one technology is used. In this case, thermal insulation can be provided with mineral wool or penoplex.

1 Insulating the walls of a country house from the inside

Before you start insulating the walls in a wooden house with your own hands, you should thoroughly clean all surfaces from dust and dirt. If the house is made using timber, then thermal insulation can be provided with penoplex or mineral wool.

Before this, wooden surfaces country house, including the surface of the ceiling, timber ribs, attic walls, and the inner surface of the roof, must be subjected to detailed treatment using a special anti-insect emulsion. All insulation work of a country wooden house, done inside with your own hands, consists of:

- Caulking cracks in the attic walls, ceiling surfaces and inside the roof as with;

- Creating a vapor barrier for the floor using timber;

- Installation of sheathing;

- Laying insulation and ensuring sealing of the roof of a country house;

- Creatures ventilation system between the walls of the attic;

- Domestic finishing works for the preparation of beams, ceilings and roofs.

In addition, when insulating the internal walls of a wooden country house made from timber with your own hands, you need to carefully monitor the condition of the electrical wiring.

For example, if the walls of a country house are made using timber, and the technology involves laying out surface wiring on the walls of the attic, then it does not have to be separated from the wall surface.

To do this, just hide the wiring in special decorative casings. The wiring will be safe inside them.

After the walls have been cleaned and the thermal insulation has been prepared, you need to caulk all existing cracks.

Caulking is carried out not only on the surface of the attic walls, but also on the inner surface of the roof. It is known that in the case when a house is built using timber, the floor, attic walls and inner surface of the roof are re-caulked only a year after the building is put into operation .

In the case where people immediately began to live in a house built from timber, drying the ceiling, floor and inner surface of the roof will be much slower.

Based on this, it makes sense to carry out the second caulking no less than after 2-3 years. By the way, in most cases jute fiber is used to caulk the walls of a house made from timber with your own hands.

After this, you should begin insulating the walls with penoplex or minata. Inner surface The ceiling and roof (in the attic) can also be insulated with polystyrene foam with your own hands.

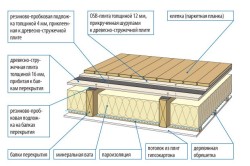

2 Creating a vapor barrier

When insulating a wooden house with your own hands, it is extremely important point is to create a vapor barrier inside the attic walls.

This is explained by the fact that the space inside the wooden base of the attic wall consists of those beams that are locked between two heat insulators.

In this case, the humidity level in the rooms will certainly increase, which will lead to the appearance of a “thermos effect” in the space from the ceiling to the roof.

This will cause the entire structure to stop “breathing.” Excess moisture is eliminated by ventilation.

The main thing is not to allow the wood to become damp, which could lead to slow rotting of the entire structure. To avoid this, before installing the heat insulator, the entire insulated wall surface must be equipped with a vapor-waterproofing film.

When implementing installation work As in the case of creation associated with sheathing on load-bearing walls made using timber, a metal profile is additionally installed.

This is especially true when finishing and vapor barrier will be carried out using moisture-resistant drywall.

After this, a strip of mineral wool is located inside, in the space between the bars. And its layers will be connected to the base of the wall using anchors equipped with enlarged round caps. A second layer of vapor barrier film is laid on top of the insulation.

2.1 Creating ventilation and wall insulation with foam plastic

A thoughtfully designed ventilation system should not have direct external type hoods in its communications.

The most suitable option is to combine the system into one circuit through the ceiling and attic communications.

This is done through ventilation ducts. Any axial fan with a low or medium power rating can be used as a supercharger.

When activating the ventilation system using winter time within half an hour, you can influence the optimal air humidity parameter.

Inside, the second layer of vapor barrier film is attached to the beams using staples from a construction stapler. After the block is installed, it should be covered with clapboard made of wood.

This will give the room a certain degree of aesthetic appeal and insulate its contour. In addition, it is advisable to decorate the inside of the room with a vertically positioned plank.

In addition, the walls can be insulated from the inside using polystyrene foam. It makes sense to begin installation work with the selection of suitable sheet sizes. They can be much thinner than with external insulation work. Foam is different:

- Simplicity and ease of installation;

- Low degree of thermal conductivity;

- High noise insulation characteristics;

- Long service life.

When insulating the internal walls of a wooden house with a material such as penofol, convection and significant heat loss through the cracks will be permanently stopped due to the fact that the caulk was produced poorly.

If the beam has a relatively small thickness, then frost will not form in the corners and on the walls of the house in the winter season. When using polystyrene foam, the room space from floor to ceiling will warm up quite quickly.

2.2 Floor insulation

In addition to a set of obvious advantages, when the wooden floor is insulated, the level of heat loss in the house will be significantly (up to 20 percent) reduced. An example of this.

The simplest and most effective method of floor insulation involves the use of mineral wool as insulation.

The technology of insulation using mineral wool itself is quite simple and inexpensive. It is especially important to insulate the floor using mineral wool when it is mounted directly on the ground surface.

The choice of type of heat insulator directly correlates with the features of the floor arrangement. So, if the installed insulation will not be subjected to regular technical loads, it is recommended to opt for mineral wool with a density of 50 kg/m3.

If the load on the slabs is carried out with a periodic frequency, then the maximum density of the minislab can reach 160 kg/m3.

In this case, the material is not mounted using fasteners, but is laid freely. Another option for insulating a wooden floor involves the use of penoplex.

First you will need to dismantle the old coating. After this, you need to take care of installing the waterproofing layer.

Polyethylene can be used for this purpose. Afterwards, you can begin to apply penoplex, which is characterized by low hygroscopicity.

In some cases, you can insulate the floor of a wooden house using foam boards. You can use one of its varieties for this - polystyrene foam, which is a fairly relevant heat-insulating material.

The whole process begins with the formation of a gravel cushion on the ground, the thickness of which can reach 30-40 centimeters. This layer is thoroughly compacted, after which purified sand is poured on top in a layer of 10 centimeters.

2.3 Ceiling insulation

Currently, despite the colossal abundance of insulation materials on the modern construction market, a large number of homeowners prefer to insulate the floors in a wooden house the old fashioned way - with sawdust.

This method is primarily characterized by its high environmental friendliness and relative cheapness.

However, the work associated with the presented material is quite troublesome. In addition, this method requires some preliminary preparation.

For example, before starting insulation, sawdust must be thoroughly treated with an antiseptic in order to avoid the appearance of mold.

Sawdust should also be sprayed with a fire retardant in order to improve their fire-resistant qualities as with. Before backfilling, this material must undergo prolonged drying.

And in order to prevent rodents from getting into the insulation, it needs to be diluted with powdered lime. This mixture must be poured into the resulting voids.

Moreover, its layer can reach a height of 20 centimeters. For floor insulation, the following can be used: modern materials, such as mineral wool, polyplex, expanded clay and foil-type polyethylene foam.

It’s a good idea to use alternative insulation materials such as glassine. It can cover foam boards.

Insulation of a wooden house from the inside - layout of materials

When choosing a particular material special attention is paid to the financial capabilities of the owner of a wooden house. Based on this, you should decide on the price segment in which this or that insulation is located.

2.4 How to insulate a wooden house made of timber? (video)