The growing popularity of frame structures is due to several factors, the main one being the speed of construction. Just a few weeks and you can start arranging a cozy home.

Rising real estate prices leave less and less chance for the average family to acquire useful space. And frame construction provides a real chance to purchase a dream home, and even taking into account individual preferences in layout and decoration.

Advantages of frame construction

Operational assembly. In just two weeks to several months, a turnkey house with all communications can appear on the site.

Affordable price. When creating a project, all possible options for saving on finishing and structural elements are taken into account.

Environmental friendliness. The house will indeed be absolutely safe for the health of the people living in it if it is finished with non-toxic materials.

Energy efficiency, due to the design and economical consumption of energy for heating the room.

Durability. Warranty periods define a service life of over 50 years. Any building needs maintenance and repair. With timely care and replacement of insulation, if necessary, the structure has a similar service life to a brick house.

Read also: Self-leveling floor (photo): types and features of materials, pouring technology

High strength allows you to withstand a magnitude 7 earthquake.

Frame installation can be produced at any time of the year.

Disadvantages of frame construction

Difficulty in redevelopment;

After 10 years, with proper installation, it is necessary to replace the insulation (if mineral wool was used).

Other complaints about low-rise construction, thermal insulation and short service life have already been dispelled. New developments in cottage villages consist of 2-3 floors.

Types of frame construction

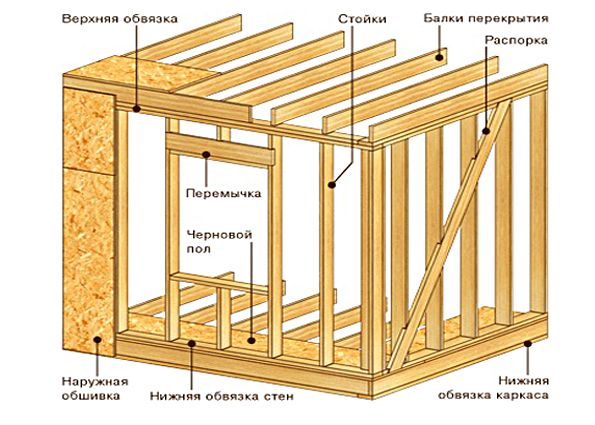

The post-and-beam structure is distinguished by a large number of notches, tie-ins and tenon ties;

The frame frame, which has floors, is assembled from autonomous platforms with a rack connection;

The design with threaded racks has high strength due to the load-bearing capacity of the racks located along the entire height of the building;

A frame-rack structure differs from a post-and-beam structure by deepening the posts into the ground to perform the function of piles;

Hybrid technology is used according to individual indications and includes elements of different types of frames.

Materials used

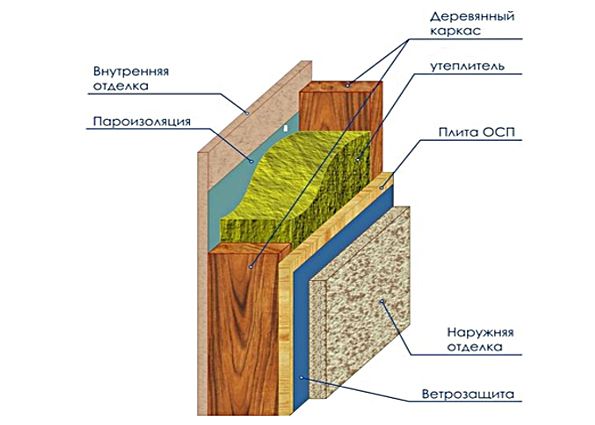

Steel profiles of different widths;

Wooden beam;

Metal corners;

DSP and OSB sheets;

Insulation (mineral wool, polystyrene foam);

Read also: Floor insulation with polystyrene foam: advantages and grades of material, insulation process

Waterproofing;

Vapor barrier;

Finishing and facing materials.

Foundation

The frame design benefits from its light weight. If there is no heavy load, it is permissible to use a strip, column or pile foundation. Due to this, there is a saving in the cost of earthworks and the cost of concrete, and the construction time is also reduced. Often, country houses are installed on a leveled surface with concrete slabs.

When constructing cottages, the project includes a basement or ground floor. In this case, a recess into the ground to the height of the basement is provided.

Design

To start construction, you can use a ready-made project or order a custom one. Before starting calculations, you need to examine the type of soil and the location of the building on the site. After this, the specialist develops documentation including:

Layout;

Communication lines (supply to the house and indoor wiring);

Heating and ventilation systems;

Structural parts of the frame;

Decoration inside the house;

Location of windows/doors;

Facade cladding.

After drawing up the plan, the necessary materials are calculated. Particular attention is paid to quality, because the durability of the building largely depends on the properties of the materials used.

Read also: House made of foam blocks

Stages of building a frame house

Preparing the site for development: clearing the area and leveling the surface.

Construction of the foundation. Surface waterproofing.

Laying communication lines.

Preparation of materials for use: treatment of wooden elements with an antiseptic solution and fire retardant (fire-retardant compound).

Making the bottom trim using anchor bolts.

Installation of sewer and water pipes.

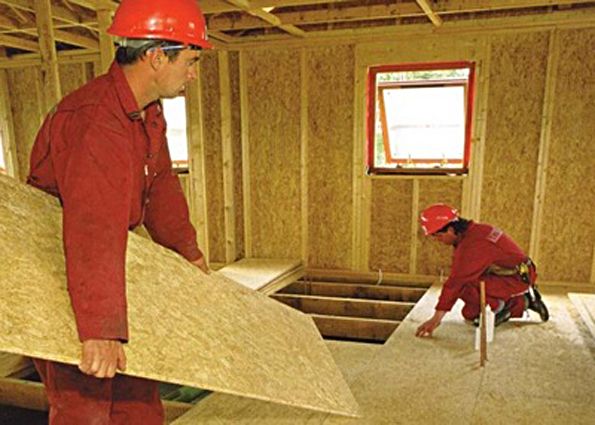

Rough floor covering with insulating layer.

Fastening the frame posts, maintaining the distance according to the technology.

Carrying out the top trim with the installation of jibs.

If a second floor is provided, install racks.

Installation of roof frame and covering.

Wall cladding with DSP or OSB sheets.

Installation of windows/doors.

Insulation of walls and ceilings.

Fastening vapor barrier, waterproofing.

External cladding.

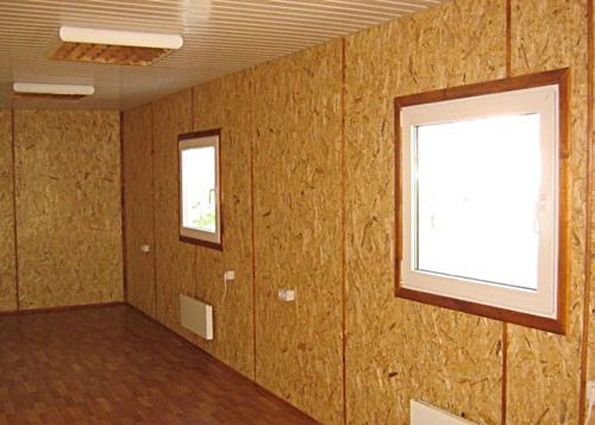

Interior decoration.