Modern market items upholstered furniture filled with a wide variety of products.

We offer all kinds of designs of sofas and armchairs, made in original upholstery, equipped with interesting and convenient systems transformation.

However, the most significant criterion when choosing suitable upholstered furniture is the filler.

In the production of soft elements of sofas, two main types of fillers are used: spring block and polyurethane foam.

Sofas with springs

The spring block is a structure of combined steel springs fixed in a vertical position. There are several types of spring sofa fillings.

1. Bonnel springs– classic reliable double-cone steel springs with four or five turns, connected to each other by spiral wire or staples. All springs included in the block are quite firmly fastened into a single structure, imparting characteristic rigidity.

Advantages:

Practicality. It has progressive elasticity: the higher the load, the greater the resistance, which makes it possible to withstand large weights (more than 110 kg).

Attractive price. The best option “quality-price”.

Reliability. Fixing the springs in the block prevents the coils from touching, deforming and does not create creaking.

Quality assurance. Long service life while maintaining the properties of elasticity and resilience.

Flaws:

Susceptibility to deformation. Vulnerable to sudden point loads (frequent jumping and walking can deform the structure and cause creaking).

Read also: Plastic boats for fishing, hunting and recreation: types, features, popular models

Weak orthopedic effect. When one spring is pressed, other neighboring springs also contract.

Expensive repairs.

Obsolescence. Outdated production technology is inferior in quality to more modern sofa designs.

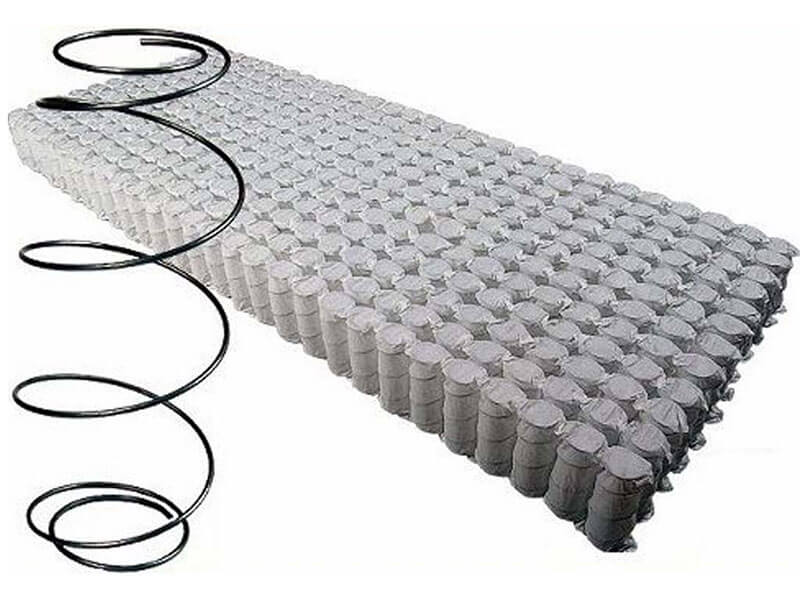

2. Pocket spring block– independent springs, cylindrical in shape, made of hardened steel wire of a certain grade, hidden in textile pocket covers, sewn together.

2. Pocket spring block– independent springs, cylindrical in shape, made of hardened steel wire of a certain grade, hidden in textile pocket covers, sewn together.

Advantages:

Elasticity. Flexible connections allow each individual spring to exhibit high elasticity, thereby achieving a better orthopedic effect.

Comfort. There is no effect of “swinging on the waves”, resulting in the formation of best conditions for good sleep and rest.

Hygiene. Provides good air and moisture circulation.

Hygiene. Provides good air and moisture circulation.

Long service life (subject to proper use of the sofa).

Flaws:

Price. The high price is explained by the complex technology of assembling a block of independent (separate) springs.

Sensitivity of the structure to sudden mechanical impacts of directed force.

Today, orthopedic products with springs are chosen by active, modern and practical people who value versatility, functionality and reliability of purchase. Well-known manufacturers use certified ingredients in accordance with high quality standards and hygiene standards. The level of quality of the spring filling determines whether the sofa will sag and deform during use, and therefore how long it will serve its owners.

Today, orthopedic products with springs are chosen by active, modern and practical people who value versatility, functionality and reliability of purchase. Well-known manufacturers use certified ingredients in accordance with high quality standards and hygiene standards. The level of quality of the spring filling determines whether the sofa will sag and deform during use, and therefore how long it will serve its owners.

Sofas with polyurethane foam

PUF is a porous substance obtained from synthetic polymers as a result of a chemical reaction. This material is better known to consumers as foam rubber. There are several types of polyurethane foam with different characteristics. The main criterion for the quality of foam rubber is its elasticity and density. It is recommended to use a density indicator of 30 to 40 kg/m3. If a material with a lower density is used, the service life of the product is noticeably reduced. The following brands of polyurethane foam are mainly used:

Read also: Water filter for washing: types, device, tips on how to choose

ST 2236 - the material of this brand is intended for a surface load of no more than 60 kg of weight, the service life of this type of foam is short;

ST 2536 - this density grade is more consistent with the standard, creates a fairly rigid surface that can withstand a weight of 100 kg;

ST 3540 - this brand of polyurethane foam is most often used by manufacturers of modern soft products, as it is durable and comfortable, and can withstand heavy weight.

There are the following types of polyurethane foam:

Block - purchased from suppliers in huge layers and cut into individual layers of the required size and thickness. Then the sheets are glued to each other in a manner from more dense to less dense;

Cast polyurethane foam is produced using special molds that are filled with a specific liquid composition. Various parts of the required shape are cast, which makes it possible to produce unusual furniture of interesting design.

Advantages of PPU:

Price. Low cost ensures wide consumer demand.

Optimal technical and operational characteristics. A high degree of elasticity indicates a long service life of quality samples.

Read also: Metal corrosion: causes and methods of rust removal

Practicality. The moisture-resistant material is quite environmentally friendly, does not cause allergies, because it does not accumulate dust.

Versatility. Various geometric shapes of some elements are acceptable due to the flexibility and elasticity of the material.

Flaws:

Flaws:

Flammable The material ignites quickly and when burned, harmful substances are released.

Many modern manufacturers prefer to use polyurethane foam in their products, since it is easier and more profitable to work with. Particularly popular today is elastic and expensive polyurethane foam with a “memory” effect, which smoothly takes the shape of a sitting or lying person, maximally adapting to the curves of his body. In addition to foam rubber, padding polyester, holofiber, PU foam crumbs and latex are additionally used to fill soft furniture elements.

Opinions regarding best option The fillings of the sofa are ambiguous. Each consumer is free to choose what suits him best in terms of comfort and price. Obviously, both fillers have a number of undeniable advantages. However, when faced with a choice, you should always remember the main indicator that influences the choice - the quality of the constituent components. Only the use of high-quality furniture materials will make the furniture reliable, durable and comfortable.

Drainage system: materials used, composition...

Gas cylinder for a summer residence: types, volume, operating rules...

Foam rubber (polyurethane foam) or spring block.

What to choose and what not to make a mistake when choosing?

Comfort and convenience.

This quality plays an important role for any representative of upholstered furniture. Regardless of whether you need a sofa bed or a Euro-ottoman, the main purpose is the same - lying and sitting on them should be comfortable. It is important that pits do not form under your body, which is why sleep turns into torment instead of rest. The load on the mattress should be distributed evenly so that in the morning the spine and muscles are rested, and not stated: “everything hurts again, but did you rest at night?!”

What is polyurethane foam? It is a foam material made from synthetic polymers. PU foam retains its shape well and has good elasticity, which is why it is used in orthopedic mattresses. It provides the sleeping person with optimal comfort, as it anatomically adapts to the contours of the body. This material can withstand decent weight, easily restores its shape, and is hypoallergenic. High quality polyurethane foam lasts a long time.

Polyurethane foam in the sofa.

Spring blocks used as filling for furniture come in two types - dependent (“Bonnel”) and independent (“Pocket spring”).

“Bonnel” is an inexpensive block, usually consisting of 4-turn double-cone springs, which are installed in one row and connected to adjacent rows by spirals at the top and bottom.

They are also called continuous weave blocks and dependent springs. Such spring mattresses do not provide anatomical support, because... When one spring is compressed, neighboring springs are involved in the process.

It is a continuous weaving of springs and is considered quite outdated. The reason is that mattresses in which this type of spring is introduced do not allow a person to truly rest comfortably. It is simply impossible to press one spring in such a block - all its neighbors are immediately involved in the process, which makes the mattress unable to accurately adjust to the position of the body.

The main advantage of this block is that each spring is in a separate case, and is not rigidly connected to the neighboring one. This eliminates vibrations of the structure, and thanks to the effect of each spring on the body, the load is distributed evenly over the entire area. This provides an “individual approach” to different areas human body, giving the entire spring mattress particularly pronounced anatomical properties. If you are looking for the best spring mattress, then you should choose one with independent springs. independent springs things are going better. In this block, each spring “lives” on its own, in a separate bag, which allows you to distribute the load very accurately, thus providing a person with the opportunity for a restful, full sleep. Therefore good orthopedic mattress it is equipped with either an independent spring block or first-class fillers (latex is considered the highest quality). It is this mattress that allows a person to feel fresh, alert and full of energy in the morning.

This means we need to move on to consider the next parameter. Independent springs are the basis of good spring mattresses. Springs are made from the same materials as the springs of the Bonnel block, but their diameter is much smaller - up to 2 cm, the number of turns reaches 8, and the number of springs per square meter - from 250 to 1200. As a rule, such springs have a barrel-shaped form.

Durability and wear resistance.

Polyurethane foam lasts a long time, of course, if you set yourself the goal of destroying it and methodically train gymnastic jumps on your favorite sofa, then after some time it will certainly lose its elasticity. With normal use, upholstered furniture using high-quality polyurethane foam has a very long service life. In addition, this material does not accumulate or emit dust, is absolutely safe and allows air to pass through.

Spring blocks, subject to their production technology, are also very durable. But as a result of intensive use of a sofa or mattress - jumping, skipping or walking on it, the springs still have a much greater chance of sagging or breaking. This is especially true for cheap spring blocks. Other unpleasant consequences of their use include creaking and damage to the casing, through which the springs sometimes tend to peek out. To restore justice, it is worth noting that attempts to look into real world are characteristic mainly of springs in furniture, which falls into the “can’t get cheaper” category. In a well-made sofa, even an economy class one, there are enough intermediate layers between the block and the outer upholstery so that the springs remain where they should be for duty.

Spring block.

However, we have to make a reservation that if dependent springs are used in upholstered furniture, then polyurethane foam wins.

PPU is cheaper than a good spring block. Bonnel has long since become an obsolete technology and cannot compete with more modern units, so the price for such springs is very low. But polyurethane foam can be different. The durability and comfort of your upholstered furniture will directly depend on its quality. So, if you want to save money on your purchase, save wisely so that you don't end up with a chair with a dented hole in the middle, or a sofa that looks more like bumpy terrain than a pleasant place to relax. Ask the seller about the quality of the filler used in this particular model. Try to see if you are sitting comfortably, if you feel comfortable. Of course, price is always important, but in this case you should not give preference only to it. Buying a sofa bed is a long-term purchase. And throughout this period, the furniture must retain its original properties - comfort, attractive appearance.

Who won our battle?

Judging by the above, polyurethane foam wins. But you understand that there can be no definite answer to such a question. Both polyurethane foam and springs have their own strengths and weaknesses, and the final choice in favor of one filler or another can only be made based on personal preferences.

Upholstered furniture made on the basis of both polyurethane foam and a spring block can be good and of very high quality. Look at different models, this can be done directly on our website, compare them. Our store consultants will be happy to tell you about the features of filling each of them. Whether it will be spring or springless depends only on you. For our part, we guarantee its quality. It is important to us that the selected upholstered furniture pleases you for as long as possible!

Modern sofa manufacturers mainly use two types of fillers for their products: polyurethane foam or spring blocks. Accordingly, when purchasing this piece of furniture, each buyer thinks first of all about what content is suitable for him. It should be noted that each of these materials has its own advantages, which means that it can be best used for certain purposes.

Advantages of spring blocks

For example, a spring block can withstand heavy loads, which is perfect for people who are heavy. And a layer of batting or spunbond laid on top hides the unpleasant sensations from using steel wire. Manufacturers, as a rule, talk about the special elastic properties of spring blocks, which allow such filler to take the shape of the body of a lying person, distributing the load on the spine.

Sofa with spring block

In fact, the orthopedic properties of spring blocks are rather weakly expressed, because as each spring contracts, it pulls the neighboring ones connected to it.

But despite all this, reliable fixation springs and the use of technologies that make it possible to increase the resistance force with increasing load, allows us to talk about the durability of the use of sofas on a spring basis. At the same time, much, of course, depends on the characteristics of the use of the furniture. This filler is quite durable, but does not withstand large point loads, so if there are small children in the house who like to jump on upholstered furniture, the springs can quickly fail.

Advantages of polyurethane foam as a filler for upholstered furniture

Modern industry uses polymers in a wide variety of applications, from building blocks and insulation of car interiors to filling children's toys. Furniture production has not escaped this trend either. PPU filler is widely used in the manufacture of upholstered furniture. So what is this in the sofa?

Polyurethane foam sheet

Polyurethane foam (another name is PUF) is a synthetic porous substance that consists of thick-walled cells filled with air. Depending on its characteristics, it can be made in the form of soft and thin sheets (foam rubber) or fairly hard and thick slabs (actually polyurethane foam).

The advantages of polyurethane foam are its reliability and durability - this material is able to restore its shape more easily than all others, while correct use will extend its service life for many years.

Another advantage is several options for rigidity. Depending on the brand, it can withstand loads from 60 to 100 kg, and the densest samples, often used in modern furniture, are also suitable for people of greater weight. Therefore, when choosing a filling such as polyurethane foam, it makes sense to further clarify the density indicator, which should be over 30 kg/m3. This information can be obtained by carefully studying the passport of the model you like.

PU foam density options

One of the important properties of polyurethane foam is its ability not to accumulate dust and absolute hypoallergenicity. This trait is especially important for people prone to different types household allergies. In addition, during production it is additionally impregnated with an antifungal and antibacterial composition, which makes polyurethane foam completely harmless to health.

IN furniture production Mainly two types of such material are used - cast and block:

- for the sofa , filled with block polyurethane foam, parts are cut out from large sheets of varying degrees of density and glued together in such a way that the softest material is on top and the base is harder;

- cast polyurethane foam is initially in a liquid state; it is cast into molds, from which, under pressure and temperature, a solid block emerges, exactly repeating the shape of the necessary parts. This method allows you to achieve a particularly smooth shape of upholstered furniture.

Disadvantages of PPU

The disadvantages of this material are that it does not tolerate long stay under straight lines sun rays, starting to break and become discolored. Therefore, manufacturers strive to make covers from light-proof materials for parts.

Also, polyurethane foam is a flammable material, releasing harmful substances when ignited.

Many buyers, accustomed to sofas with spring blocks, may find products made from dense polyurethane foam too hard.

Sofa with PPU filling

Dependence of the cost of a sofa on its “filling”

When choosing fillings for a sofa, you must also pay attention to the cost of various samples: sofas based on polyurethane foam or polyurethane foam have a lower cost due to production technology.

So, when deciding which is better to choose, polyurethane foam or a spring block, you need to decide on the parameters of this choice.

The cost of polyurethane foam is much less, and furniture based on it has more various forms. Moreover, both materials, subject to operating rules, are durable and easy to use.

The best decision will be one that is made based on those characteristics that are important for a particular buyer and depend on the characteristics of the further use of the sofa. The ability to test a sofa before purchasing by sitting on it and making sure that the density of the filler is optimal and the surface is not uneven will also help when choosing.

Upholstered furniture is a serious purchase. Everyone wants her to please for at least 10, and preferably 20, years. When choosing a sofa you need to consider appearance and him quality characteristics. Before buying, you need to ask yourself which filling for the sofa is better. The comfort, ergonomics and durability of the sofa will depend on this.

Manufacturers of upholstered furniture present many types of sofas:

The last type of sofa is suitable for rooms with a bay window, since ordinary ones will not fit into such an interior. Each type of sofa has its own price range and technological characteristics.

Let's look at what types of fillings there are in order to understand which filling to choose for a sofa.

Spring blocks

Spring blocks have long been used in upholstered furniture. This is one of the oldest fillers. The spring block makes the sofa elastic and comfortable. Manufacturers especially often install spring blocks in double sofas (Eurobook type). Blocks can be dependent or independent.

Dependents

The springs are interconnected. When pressure is applied to one spring, pressure is applied to the adjacent one. Springs can have different diameters. The smaller the diameter, the higher the density and vice versa. The top of such blocks is usually covered with polyurethane foam and coconut board.

Independent

Each spring is packed in a fabric case. They compress under the body part independently of each other and create comfort for sleeping and sitting. Mattresses are made from such blocks. Therefore, they are usually used in beds rather than sofas.

Wave springs

This type of spring is the base for the sofa. They provide the necessary rigidity and comfort. Springs are now installed in sofas, armchairs, and chairs. Other fillers, such as polyurethane foam, are placed on top.

Elastic straps

They are, like wave springs, a base that is attached to the frame of the sofa. Depending on the tension, the calculated rigidity is given and the cushion is installed.

Polyurethane foam

Probably the most common filler. The second name for polyurethane foam is foam rubber. Thanks to its plasticity, manufacturers can recreate fancy shapes in pillows.

Foam rubber is divided into types:

- standard ST;

- hard EL, HL;

- soft S;

- increased comfort HR;

- viscous elastic LR.

The rigidity of PU foam reflects the degree of compliance of the walls of the bubbles. The lower the rigidity, the easier it is to push through the polyurethane foam, that is, the softer it is. Indicated by the second digit of the PPU brand. Polyurethane foam with high rigidity is used in formative elements, as well as for shelling the frame. Polyurethane foam with reduced rigidity - in the seat and back. At the same time, the rigidity in the backrest will be lower than in the seat, since it bears the main weight of the person, and if there is insufficient rigidity, he will simply fall down to the frame. However, excessive rigidity leads to the fact that sitting will be uncomfortable, like on a stool.

ST (Standard) - popular and often used fillers. They are used in any part of the sofa - from lightly loaded ones (armrest) to seating areas that can withstand a load of more than 90 kg.

EL, HL (Enhanced Loadbearing, High Loadbearing) – rigid foams with high load-bearing capacity. They are used mainly to create a configuration (for example, for shelling a frame).

S (Soft) – soft foam. Used in back cushions and sandwich seats

HR (High Resilience) – highly elastic foams. These are more expensive brands. They are used to provide greater comfort. Unlike standard PU foam, inside HR the air bubbles have different sizes, and the walls between them are of different thicknesses, which gives the PU foam special properties. During initial loads (when a person is just starting to sit on the sofa, but has not yet sat down completely), large bubbles begin to work, since air comes out of them faster, and the person feels soft when sitting down. As the load increases, smaller bubbles begin to work, which resist more strongly, providing a supporting effect. Thus, HR PU foam has two properties: pliability and elasticity at the same time. Such foams are comfortable for both a person with a large mass and a small one.

LR – viscous elastic or memory foam. The most expensive foam rubber. It conforms to the body's shape and provides the best comfort. If there is no strong pressure on the pillow, it returns to its original position.

Manufacturers create original pillows in the form of so-called sandwiches. Sandwich is a combination of several brands of polyurethane foam with different properties of the soft element, which gives the pillow design increased comfort.

Molded PPU (FPPU)

Pillows are obtained as a result of the interaction of chemicals that are poured into specially made molds. The part is produced under the influence of pressure and temperature. The advantages of the method are the high quality of the workpiece and smooth shapes. FPPU is the most durable of all categories of polyurethane foams.

If something fails (for example, removable pillows), replacement is done at home with your own hands. You just need to contact the manufacturer, who will make a new soft element, and then insert it into the case.

Soft fillers

Among the soft fillers, the following stand out.

Britfil (holofiber, synthetic fluff)

Everyone knows artificial filler with different names. The fibers of the material create a strong, springy structure. Britfil compresses well and “breathes”, and is anti-allergic.

Despite all the advantages of this material, to work with it you need certain technological support for production:

Sintepon

This is a synthetic material in the form of a non-woven fabric. Mainly in the furniture industry they are used for wrapping parts to hide any technological transitions (additional layer).

Periotec

Canvas large sizes made from natural or synthetic fibers. The material has different densities and is more often used in removable back cushions.

Having become familiar with brief description sofa fillers, the buyer must decide for himself which one will be better.

Selecting upholstered furniture is not an easy task, even if buyers have an excellent sense of style and know in advance what kind of sofa design they need. It is very frivolous to rely only on aesthetic ideas, since upholstered furniture is purchased for a specific practical purpose - to organize the most comfortable place for rest and sleep.

Types of fillers

Despite the fact that furniture showroom managers use dozens of names to describe this or that type of filler, in practice only two main ones can be distinguished:

spring block;

polyurethane foam (PPU).

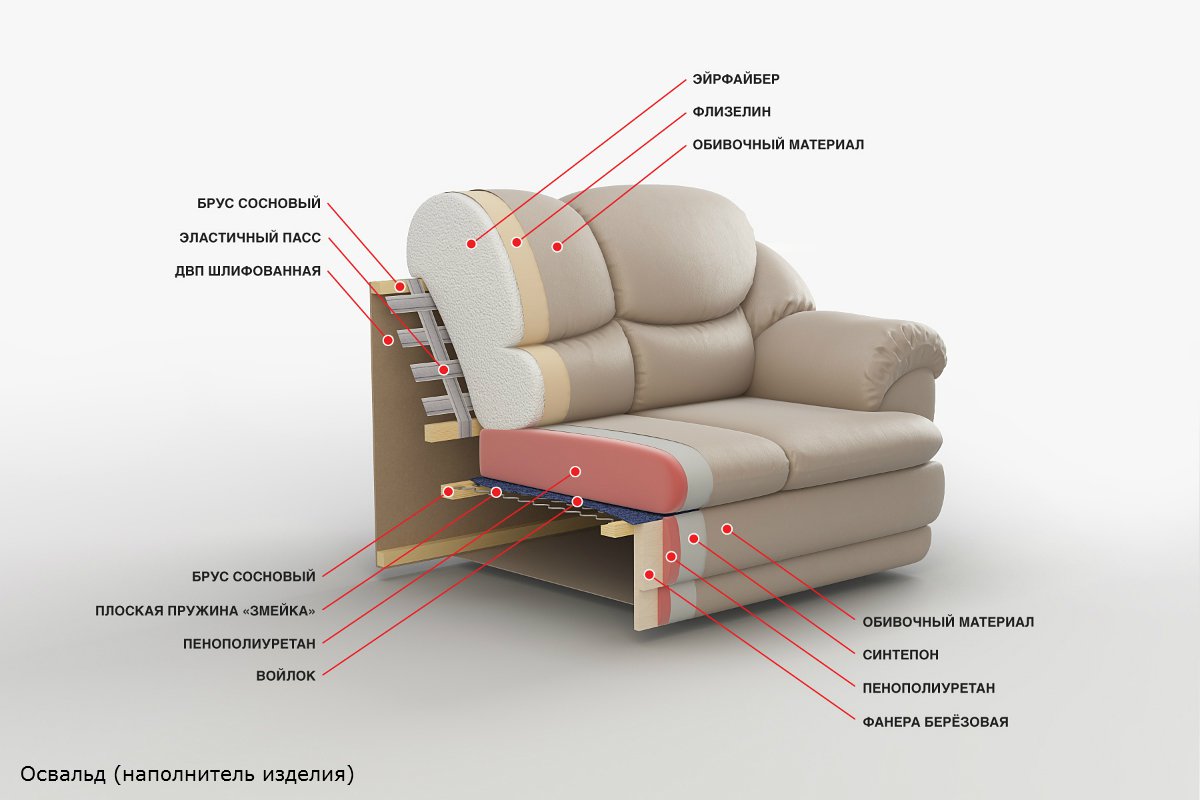

By the way, if polyurethane foam can be used in “ pure form", then the spring structure is always “wrapped” in additional layers of covering materials.

A comfortable sofa should be both soft and resilient. It is believed that only a spring block can provide a high orthopedic effect. This is true, but there is one problem. Springs must be of high quality. Unfortunately, not every manufacturer can now guarantee their structural strength. A sofa with such springs quickly turns into a shapeless, uncomfortable trestle bed.

Polyurethane foam is a fairly cheap material, but it can be manufactured with different densities:

standard;

soft;

hard;

highly elastic.

If we compare these two fillers in monetary terms, then polyurethane foam is several times cheaper. Considering that the principle of its “action” is the same as that of springs (when pressed it collapses, and when the pressure is released it returns to its original shape), manufacturers prefer to use it much more often.

Production technology

For making spring sofa You will need to find not only high-quality springs, but also covering materials (coconut coir, foam rubber, horsehair). Depending on their type, the model is given not only the necessary elasticity and softness, but also shape. The technological cycle for manufacturing spring furniture is complex and expensive, so it is usually resorted to by those factories that specialize in such production, have long-standing traditions, and strive to maintain a certain corporate style.

Furniture made from polyurethane foam is made according to the layer cake principle, that is, layers (blocks) of varying densities are used. The seats and backs of sofas and armchairs are assembled like a construction set: parts are cut to the required size, glued together on a special machine and “dressed” in covers.

There is another subspecies - cast. The creamy mixture of polyurethane foam is filled with the blank of the future chair or sofa. After it hardens, a finished model element is obtained. This technology is used for the manufacture of exclusive modern furniture. It has a fancy design and is usually higher in cost than corner sofas and laconic sets of upholstered furniture of regular shape that have become standard. "Casting" has a disadvantage. During the reaction process, a kind of crust appears on the surface of the polyurethane workpiece, which prevents air exchange.

How to choose a sofa and armchairs

The sofa traditionally carries the greatest load. It can be not only a place of rest, but also a bed on which one of the family members will sleep every day. Depending on this, the filler, its density and composition are selected. It would be useful to take into account the “passability” of the room. The greater the number of people in the house, the more responsibly you need to select a model. Its resource must be designed for active use. Doctors do not recommend using too soft mattresses for sleeping. This recommendation should also be applied when choosing a sofa.

Knowing the features of each filler, it will be easier to navigate the huge range of upholstered furniture. At the same time, one should not forget about one important rule: the reputation of the factory matters.

The quality of work must go hand in hand with the quality of the materials from which the furniture is made. They must first of all be safe, not contain harmful substances. Information about the environmental and technological compliance of the selected model can be found in the passport or certificate.