Factory marking of wires and cables is a designation on the insulation, which is a kind of code of letters and numbers that display the characteristics of the product. Today, every manufacturing plant must indicate a special code on its products, which is standardized in advance so that every seller can know the decoding.

Purpose

The purpose of the cipher is to display the main characteristics, namely:

- core material;

- appointment;

- type of insulation;

- design feature;

- cross section of the product;

- rated voltage.

Main variety

Today for electric installation work cords are used. Before deciphering the markings, it is necessary to understand what these products are and what their differences are.

Wires

A wire is an electrical product consisting of one or more wires twisted together, without insulation or insulated. The core sheath is usually light and not made of metal (although wire wrapping is also common).

Exposed conductor

Such products can be used in electrical installation work(for example), as well as in the manufacture of electric motor windings. Today there are wires with copper and aluminum conductors. The copper version quickly oxidizes in open space and has a high price, but at the same time it is able to pass through higher current loads. In addition, copper is more elastic, which means it will not break as quickly. Aluminum ones are more fragile and are not connected to copper ones (except perhaps through terminals), but for that they have a low cost. Today it is used less and less.

It should also be noted that the contacts may be insulated or bare. The latter option is used for power lines. An insulated wire can be protected or unprotected. Protection is provided by another layer of insulation (made of plastic or rubber), which covers the sheath of the cores.

The last classification is carried out depending on the purpose: mounting, power and installation. The mounting wire must be copper; it is used, as a rule, to connect elements of an electrical circuit in a switchboard, as well as to connect circuits in radio equipment. Power (as well as installation) is better known to us, because used outdoors and indoors.

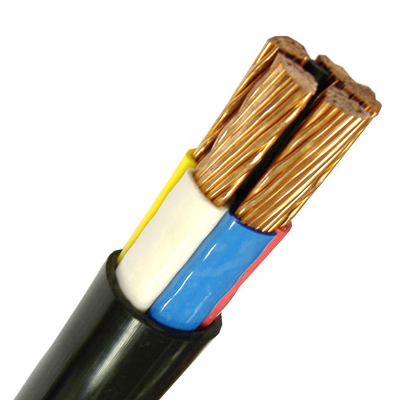

Cables

An electrical cable is a product made up of several wires that are located under one insulating sheath (PVC, rubber, plastic). In addition to this shell, there may be additional protection - an armored shell made of wire or steel tape, which must be indicated in the marking.

Aluminum wire  Copper contacts

Copper contacts

There are 5 main types of electrical cables:

- power;

- control;

- for management;

- for communication;

- radiofrequency.

Let us briefly consider the conditions of use of each product.

Power used to transmit electricity in power and lighting electrical appliances. There are products various types and appointments. Power cables are mainly used for external (both overhead and underground) and internal (in residential and non-residential premises). Power cables can have both aluminum and copper conductors. It is recommended to give preference to the latter option. The insulating layer can be PVC, paper, rubber, polyethylene, etc.

Control used for work electrical devices, which transmit an information signal to control any devices. This type can also be with aluminum and copper conductors.

Cable management It is a copper electrical conductor with a protective shield. Applicable in various systems automation. Protective screen serves to remove interference, as well as protection from mechanical damage.

Cable communications used to transmit information using currents of various frequencies. Transmission of local communication lines is carried out by low-frequency conductors, and long-distance lines - by high-frequency ones.

Radio frequency The cable is used in radio engineering devices. The main purpose is the transmission of video and radio signals.

Cords

The cord consists of several (at least two) elastic strands of small cross-section (up to 1.5 mm2). The cord cores consist of many intertwined wires, the insulation of which is carried out by a non-metallic sheath. Typically, cords are represented by multi-core products, but there are also two-core ones, which are used if the housing of the electrical appliance does not require special grounding. Today, cords are used for connecting to the network (for example, a refrigerator or microwave oven).

So we have figured out the main differences between all three types of electrical products. We hope that the information was accessible to you. We also recommend watching the video in which this information presented more clearly:

Main characteristics and differences of conductors

General Differences

All conductors may differ in the following ways:

- Cross section. There are cores with a cross section of 0.35 mm2. up to 240 mm.sq.

- Manufacturing material: copper, aluminum, aluminum-copper (a special composite of two metals).

- Rated voltage (for example, can withstand 220 or 380V).

- Number of cores (single-core or stranded).

- Insulation material (PVC, rubber, paper).

- Protective shell material (rubber, plastic, metal).

Marking

General information

The basic standards for marking wires, cables and cords according to GOST are the same, so first we will consider decoding the letter code in electrical engineering.

Resize

Marking of wires and cables.

Marking electrical wires, cables and all cable products was invented with the aim of recognizing, purpose and scope of their use.

The markings are not so easy to understand and decipher. Marking electric cable contains many signs and symbols, and sometimes even colors. Each of them means something.

When purchasing wires, specialized stores have salespeople who will advise and can help you choose the right cable. But sometimes, you need to figure out the conductor markings yourself.

Cable marking, basic principles.

Typically, a conductor consists of one or more copper and sometimes aluminum intertwined strands. The conductors may be in a separate insulating sheath or without. Copper wires are more popular; they are strong, flexible, can withstand high electrical voltage and are not as brittle when compared with wires made of aluminum.

Conductors can be divided into purpose groups into power wires, installation wires and cables for installation.

Let's look at what the cable actually consists of. First of all, the cable consists of wires that are in one insulating sheath. You can also find insulation made from a steel shell.

For electrical wiring Power cables are used. Control cable for wiring through which the signal is transmitted. Control cable - used in automatic systems. Radio frequency communication cables are used in radio engineering.

Cables and wires differ in cross-section (mm2), rated voltage, number of cores, and metal used for their manufacture. The cores of wires and cables can be copper, aluminum or aluminum-copper alloy. The cable sheath and insulation can also be made of various materials. All this is encrypted in the cable markings.

The first thing you should pay attention to when decoding is the marking of the cable insulation, or rather the letters on it.

The first letter encrypts the metal from which the wire core is made. Aluminum is marked with the letter “A”, copper wires are not marked in any way, therefore if there is no letter “A”, the cable core is made of copper.

The second symbol tells what type of wire:

- flat [P],

- mounting [M],

- control [TO],

- mounting with flexible core [MG],

- installation [P(U)] or [SH].

The third character in the marking code is responsible for the material from which the insulation is made.

Insulation is made from:

- polyvinyl chloride [V/VR],

- rubber insulation [R],

- insulation material is made of fire-resistant rubber, nayrite [N/NR],

- polyethylene insulation [P],

- nylon [TO],

- seam insulation [F],

- insulation material enamel [E],

- varnished insulation [L],

- polyamide silk [SH],

- braided polyamide silk [ABOUT],

- glass fiber insulation [WITH],

- shielded insulation [E],

- there is a support cable in insulation [T],

- the insulation contains a flexible core [G].

Wires protected by rubber insulation are sometimes protected by a PVC sheath or a sheath of Nairite. Then the markings of the wire cores are indicated after those described above.

The fourth symbol indicates the conductor design. The symbols of the fourth group mean:

- asphalted cable [A],

- tape armored cable [B],

- flexible, unprotected wire (cable) [G],

- round wire armored cable [TO],

- wire for pipe use [T],

- wire with additional protection in the form of braiding [ABOUT]

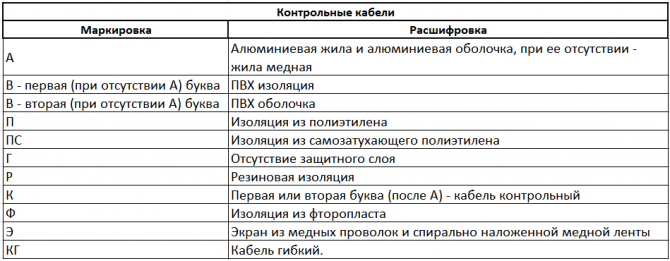

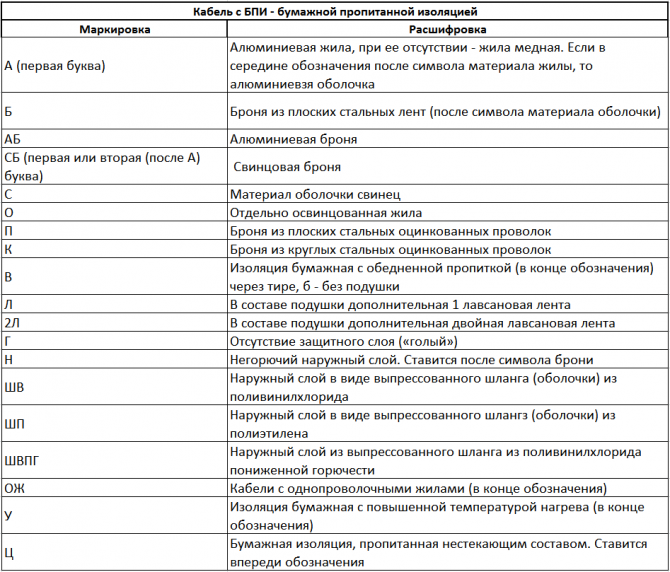

Marking of power cables, control cables and cables with BPI.

![]()

Usually there are numbers next to the letter designation of the cable marking.

- The first number on the left indicates the number of cores. When the number is not indicated, it means that there is only one wire in the wire.

- The second is the cross-sectional area of the cable in sq. mm.

- The third digit of the marking indicates the rated network voltage.

When marking, not only alphabetic and symbolic markings are used, but also color markings of wires.

Installed according to GOST 28763 following colors- grey, white, red, blue, purple, green, brown, yellow, black, orange.

The combination of yellow and green colors is used only to indicate the ground wire!

When marking wires by color, both single-color designations and color combinations are used.

Cable marking table.

All of the above is true only for products Russian manufacturers wires and cables. Abroad, marking of wires according to colors of a different standard is accepted.

Table of markings of imported cables.

Wire markings, decoding:

Marking of cable cores.

Some standards require color marking of the cable cores; this is done in order to characterize its functional purpose.

Basically, these standards are not widespread, but some have been standardized in international metrology organizations and are also recommended by them for widespread use as marking; an example of such marking is twisted pair (marking of communication cables).

Optical cable marking.

As such, there is no uniform marking of fiber optic cables.

Each manufacturer labels their products differently and this is a very big problem; therefore, to decipher each specific fiber optic cable, you will have to go to the manufacturer’s website. For more than 10 years, consumers have been begging fiber manufacturers to standardize on a single label. However, each manufacturer retains its marking, either out of inertia, or out of habit.

All foreign manufacturers (Germany, USA, France and Britain) have long unified the marking of fiber optic cables.

This is one of the popular types of cable with copper cores. The marking of the copper cable is VVG, which stands for vinyl - vinyl - bare, which is intended to transmit and distribute electricity. Consists of two layers, the material of which is polyvinyl chloride. Rated frequency 50 Hertz, at voltage 220-380V or 660-1000V.

The VVG cable is supplied in single-wire or multi-wire versions (see the table “Cable brands” below). Stranded - from 2 to 5 conductive wires plus a neutral conductor, which may be absent. The cores are marked in accordance with international standards. Zero is blue or cyan, grounding yellow-green.

Cable brands.

| Cable brand | Core cross-section | Number of cores | Cable Description | Cable purpose |

| AVVG | 2.5-5О | from 1 - 4 cores | The cable uses aluminum core, sheath and polyvinyl chloride insulation. Power. | |

| AVRG | 4-3OO or 2.5-3OO | from 1 - 4 cores | The cable uses an aluminum core, a polyvinyl chloride sheath, and rubber insulation. Power. | |

| ANRG | 4-3OO or 2.5-3OO | from 1 - 4 cores | The cable uses an aluminum core, an oil-resistant sheath, non-flammable rubber, and rubber insulation. Power. | Installation by air, tunnels, channels, overpasses and bridges. |

| VVG | 1.5-5О or 2.5-5О | from 1 - 4 cores | The cable uses a copper core, sheath and polyvinyl chloride insulation. Power. | Installation via sun ducts outdoors |

| VRG | 1-24О | from 1 - 4 cores | The cable uses a copper core, a polyvinyl chloride sheath, and rubber insulation. Power. | Installation by air, tunnels, channels, overpasses and bridges. |

| NWG | 1-24О | from 1 - 4 cores | The cable uses a copper core, an oil-resistant sheath, non-flammable rubber, and rubber insulation. Power. | Installation by air, tunnels, channels, overpasses and bridges. |

| NYM | 1,5-32 | from 2 - 5 cores | The cable uses a copper core, sheath and polyvinyl chloride insulation. Power. Has an additional layer of rubber. | Installation by air, tunnels, sun protection channels, overpasses and bridges. For stationary, industrial installations. |

Wire brands.

| Wire brand | Core cross-section | Number of cores | Wire Description | Purpose of the wire |

| Automatic reclosing | 2.5-12О | 1 core | The wire uses an aluminum core, polyvinyl chloride insulation | |

| APPV | 2,5-6 | from 2 - 3 cores | The wire uses an aluminum core, polyvinyl chloride insulation, flat wire, separate base | |

| APR | 2.5-12О | 1 core | The wire uses an aluminum core, rubber insulation, cotton braid, anti-rot impregnation | Pipe installation |

| APPR | 2,5-6 | from 2 - 3 cores | The wire uses an aluminum core and rubber insulation. | Installation in wooden structures, residential and industrial buildings. |

| APRN | 2.5-12О | 1 core | The wire uses an aluminum core, rubber insulation, and a non-flammable sheath. | Installation through channels outdoors, indoors (dry and damp) |

| PV-1 | O.5-95 | 1 core | The wire uses a copper core, polyvinyl chloride insulation | Installation of a power or lighting network, through pipes or channels |

| PV-2 | 2,5-95 | 1 core | Flexible wire, the wire uses a copper core, polyvinyl chloride insulation | Installation of a power or lighting network, through pipes or channels |

| PPV | O.75-4 | from 2 - 3 cores | The wire uses a copper core, polyvinyl chloride insulation, flat wire, separate base | Installation of power or lighting networks, in partitions, hidden wiring, through pipes or channels |

| PR | O.75-12O | 1 core | The wire uses a copper core, rubber insulation, cotton braid, anti-rot impregnation | Pipe installation |

| PVS | O.5-2.5 | from 2 - 3 cores | Flexible wire, stranded copper conductors, polyvinyl chloride sheath and insulation | |

| PRS | O.5-4 | from 2 - 3 cores | Flexible wire, stranded copper cores, rubber sheath and insulation | Used in everyday life as a power cord for electrical appliances |

| PUNP (PBPP) | 1,5-4 | from 2 - 3 cores | The wire uses a copper core, insulation and polyvinyl chloride sheath | Installation of a lighting network, and for connecting low-current household appliances |

| MGS | O,O5-O,12 | 1 core | Flexible wire, copper core, silk insulation | |

| MGSHV | O.12-1.5 | 1 core | Flexible wire, the wire uses a copper core, combined polyvinyl chloride + silk insulation | Stationary and mobile installation of electrical devices |

| TRP (noodles) | O.4-O.5 | 2 cores | The wire uses a copper core, polyethylene insulation, separate base | Hidden and open installation of telephone wiring network |

Cord brands.

| Cord brand | Core cross-section | Number of cores | Description of the cord | Purpose of the cord |

| ShVL | O.5-O.75 | from 1 - 2 cores | Used in everyday life as a power cord for electrical appliances | |

| ShPV-1 | O.35-O.75 | 2 cores | Flexible cord, twisted cores, polyvinyl chloride sheath | Used in radio electronics for TV and radio equipment |

| ShPV-2 | O.35-O.75 | 2 cores | Flexible cord, twisted cores, polyvinyl chloride sheath | Used in household wall lighting fixtures like a network cable |

| SHVVP | O.35-O.75 | from 2 - 3 cores | Flat, very flexible cord, increased flexibility, polyvinyl chloride sheath and insulation | Used in household floor lighting fixtures as a network cable |

| ShRO | O.35-1 | from 2 - 3 cores | Flexible cord, twisted cores, rubber insulation, cotton or synthetic braid | P used in everyday life as a power cord for electrical appliances with increased temperature resistance |

Conductor material

Current-carrying conductors are copper and aluminum. A significant disadvantage of aluminum is its high chemical reactivity. Aluminum conductors can be directly connected only to the same ones, and then, basically, without the use of soldering. Direct contact of aluminum with copper leads to its rapid destruction, therefore, if necessary, they are connected using terminals. If high weight and cost are not critical, then copper wires are otherwise better. For proper use, it should be borne in mind that copper oxidizes in air, so the exposed parts of copper wires become tinned.

Wire marking according to GOST

First come the letter designations:

- Material: copper - no, aluminum “A”;

For cables: sheath material, for wires: “P” - wire, “PP” - flat wire, there are two or three wires; - Insulation material: R - rubber, P - polyethylene, N - nayrite, V - polyvinyl chloride;

- For cables - protective cover design.

Then digital:

- Number of cores (if not, then the product is single-core);

- Sectional area;

- Highest network voltage;

There is a standard range of cross-sectional areas, from which the desired value is selected according to the permissible current load, based on its operating conditions.

Wires

A product consisting of one, two, or more insulated or non-insulated conductors in a common non-metallic, metallic or fibrous sheath. A single-core wire is sometimes made bare - with air insulation. Stranded ones are only insulated. Insulated wire is sometimes made in a protected version to withstand mechanical stress. An ordinary insulated wire is called unprotected.

Examples of wire markings:

- APR 3*4 - 500 - three-core, aluminum, with rubber insulation, core cross-section - 4 square millimeters, maximum voltage - 500V;

- PPR 2*2.5 - 380 - two-core flat wire, copper, with rubber insulation, core cross-section - 2.5 square millimeters, maximum voltage - 380V;

- PVA - stranded copper with PVC sheath and insulation;

- PUNP - rigid wire, with a copper core, with PVC sheath and insulation;

- MGShV - mounting, multi-wire core, insulation material - polyamide silk;

- MSHV - mounting, single-wire conductor, insulation - fiber and PVC.

- TRP - telephone wire, copper core, insulation - polyethylene.

Cable marking

Cable is a product consisting of one or more cores, necessarily insulated, in a common conductive or non-conductive sheath, which may or may not be reinforced with additional protection and metal armor.

Marking of cable designations according to GOST:

- AVRG 3x95-3000 - three-core aluminum cable, core cross-section 95 square millimeters, rated for voltage up to 3 kV, insulation - rubber, sheath - PVC, no protective cover.

- AVRG is the same, but the maximum voltage, number of cores and cross-section are not indicated.

- VRG 5*2.5-380 - five-core copper cable, 2.5 square millimeters in cross-section, designed for voltages up to 380 volts, rubber insulation, PVC sheath, no protective cover.

- 4*1.5 - four-core copper cable with a cross-section of 1.5 square millimeters, with PVC sheath and insulation.

- RK-50 - radio frequency coaxial single-wire cable with a characteristic impedance of 50 Ohms.

Cord markings

- A cord is a type of wire, mainly two-core, with a cross-section of up to 1.5 square millimeters, always flexible and insulated, which is used to directly connect household appliances to the network.

Marking of cord designations according to GOST:

- ShVVP 2*0.75 - two-core cord, stranded cores, cross-section 0.75 square millimeters, with PVC sheath and insulation;

- ShRT - heat-resistant cord with rubber sheath and insulation, stranded cores.

Permissible cross-section of wires and cables

In residential buildings, the minimum allowable cables are: for group network lines 1.5 sq. mm, for lines between floor and apartment panels, to the apartment meter - 2.5 sq. mm, for apartment power distribution lines - 4 mm.

Selection of conductor cross-section

The cross-section of electrical communication lines used should not be less than the value that ensures the maximum current density for the given installation conditions. On average, based on long-term operation, this value is 1 - 3 amperes per square millimeter. The real current is found by dividing the consumer's voltage by the total resistance of the loads connected in parallel. If the line is small, then the voltage at the consumer can be taken equal to EMF source. You can also select the cross section based on the available current using the table.

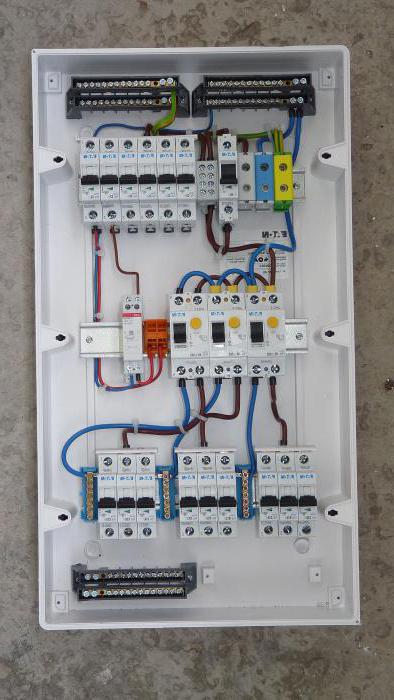

Cable shielding

Anyone who has ever dealt with wires and electricity has noticed that conductors always have different insulation colors. This was done for a reason. The colors of the wires in electrics are designed to make it easier to recognize the phase, neutral wire and ground. They all have a certain color and are easily distinguished during operation. The color of the phase, neutral, and ground wires will be discussed further.

How phase wires are painted

When working with wiring, phase wires pose the greatest danger. Touching the phase, under certain circumstances, can become lethal, which is probably why they were chosen for bright colors. In general, the colors of electrical wires allow you to quickly determine which of a bunch of wires are the most dangerous and work with them very carefully.

Most often, phase conductors are red or black, but other colors are also found: brown, lilac, orange, pink, purple, white, gray. Phases can be painted in all these colors. It will be easier to deal with them if you exclude the neutral wire and ground.

In the diagrams, phase wires are designated by the Latin (English) letter L. If there are several phases, a numerical designation is added to the letter: L1, L2, L3 for three-phase network 380 V. In another version, the first phase is designated by the letter A, the second by B, and the third by C.

Ground wire color

By modern standards, the ground conductor is yellow-green. It usually looks like yellow insulation with one or two longitudinal bright green stripes. But there are also transverse yellow-green stripes in color.

In some cases, the cable may only have yellow or bright green conductors. In this case, the “earth” has exactly this color. It is displayed in the same colors on diagrams - most often bright green, but it can also be yellow. Signed on circuit diagrams or equipment “ground” in Latin (English) letters P.E.. The contacts to which the “ground” wire must be connected are also marked.

Sometimes professionals call the grounding wire “zero protective”, but do not be confused. This is an earthen one, and it is protective because it reduces the risk of electric shock.

What color is the neutral wire?

Zero or neutral is blue or light blue, sometimes blue with a white stripe. Other colors are not used in electrical engineering to indicate zero. It will be like this in any cable: three-core, five-core or with a large number of conductors.

“Zero” is usually drawn in blue on diagrams and signed with the Latin letter N. Experts call it a working zero, since, unlike grounding, it participates in the formation of the power supply circuit. When reading a diagram, it is often defined as "minus", while the phase is considered "plus".

How to check the correctness of marking and wiring

Wire colors in electrical engineering are designed to speed up the identification of conductors, but relying only on colors is dangerous - they could be connected incorrectly. Therefore, before starting work, you should make sure that you have correctly identified their affiliation.

Take a multimeter and/or indicator screwdriver. It’s easy to work with a screwdriver: when you touch a phase, the LED built into the housing lights up. So it will be easy to identify phase conductors. If the cable is two-wire, there are no problems - the second conductor is zero. But if the wire is three-wire, you will need a multimeter or tester - with their help we will determine which of the remaining two is phase and which is zero.

We set the switch on the device so that the selected jackal is more than 220 V. Then we take two probes, hold them by the plastic handles, carefully touch the metal rod of one probe to the found phase wire, the second to the supposed zero. The screen should display 220 V or the current voltage. In fact, it may be significantly lower - this is our reality.

If 220 V or a little more is displayed, this is zero, and the other wire is presumably “ground”. If the value is less, we continue checking. With one probe we again touch the phase, with the second - to the intended grounding. If the instrument readings are lower than during the first measurement, there is “ground” in front of you and it should be green. If the readings turn out to be higher, it means that somewhere there was a mistake with “zero” in front of you. In such a situation, there are two options: look for exactly where the wires were connected incorrectly (preferable) or simply move on, remembering or noting the existing position.

So, remember that when testing a phase-zero pair, the multimeter readings are always higher than when testing a phase-ground pair.

And, in conclusion, let me give you some advice: when laying wiring and connecting wires, always connect conductors of the same color, do not confuse them. This can lead to disastrous results - at best, equipment failure, but there may also be injuries and fires.

World manufacturers household appliances When assembling their equipment, they use color coding for the mounting wires. It represents the designation in electrics L and N. Thanks to a strictly defined color, the master can quickly determine which of the wires is phase, neutral or ground. This is important when connecting or disconnecting equipment from power.

Types of wires

When connecting electrical equipment and installing various systems, you cannot do without special conductors. They are made of aluminum or copper. These materials conduct electricity well.

Important! Aluminum wires must only be connected to aluminum wires. They are chemically active. If they are connected to copper, the current transmission circuit will quickly collapse. Aluminum wires are usually connected using nuts and bolts. Copper - through a terminal. It is worth considering that the latter type of conductors has a significant drawback - it quickly oxidizes when exposed to air.

Advice in case the current stops flowing at the site of oxidation: to restore power supply, the wire must be insulated from external influence using electrical tape.

Wire classification

The conductor consists of one uninsulated or one or more insulated conductors. The second type of conductors is covered with a special non-metallic sheath. This can be a winding with insulating tape or a braid made of fibrous raw materials. Bare wires do not have any protective coatings. They are used in the construction of power lines.

Based on the above, we conclude that the wires are:

- protected;

- unprotected;

- power;

- installation.

They must be used strictly for their intended purpose. The slightest deviation from operating requirements leads to a breakdown of the power supply network. As a result of the short circuit, fires occur.

Designations of phase, neutral and ground wires

When performing installation electrical networks Insulated cables are used for household and industrial purposes. They consist of many conductive wires. Each of them is painted in a corresponding color. The designations LO, L, N in electrics allow you to reduce the time for installation and, if necessary, repair work.

The electrical designation L and N described below fully complies with the requirements of GOST R 50462 and is used in electrical installations in which the voltage reaches 1000 V. They have Electrical equipment of all residential, administrative buildings, and commercial facilities. What color designations for phase L, zero, N and grounding must be observed when installing electrical networks? Let's figure it out.

Phase conductors

Online AC There are conductors that are energized. They are called phase wires. Translated from English language The term "phase" means "line", "active wire", or "live wire".

Human contact with a phase wire exposed from insulation can result in serious burns or even death. What does the electrical designation L and N mean? On electrical diagrams phase wires are marked with the Latin letter “L”, and in multi-core cables the insulation of the phase wire will be painted in one of the following colors:

- white;

- black;

- brown;

- red.

Recommendations! If for any reason an electrician doubts the veracity of the information displaying the color marking of the cable wires, a low-voltage tester must be used to determine which wire is live.

Neutral conductors

These electrical wires are divided into three categories:

- zero working conductors.

- neutral protective (ground) conductors.

- neutral conductors, combining protective and working functions.

What is the designation of wires in electrics L and N? Network neutral or zero working conductor in circuits electrical circuits denoted by the Latin letter “N”. The neutral conductors of the cables are colored as follows:

- blue color throughout its entire length without additional inclusions;

- blue along the entire length of the core without additional inclusions.

What do L, N and PE mean in electrical engineering? PE (N-RE) is a neutral protective conductor, which is painted with alternating lines of yellow and green along the entire length of the wire entering the cable.

The third category of neutral conductors (REN-wires), which combine working and protective functions, have a color designation in electrical engineering (L and N). The wires are painted blue, with ends and connections with yellow-green stripes.

The need to check the labeling

The designation LO, L, N in electrical engineering when installing electrical networks is an important detail. How can I check if the color coding is correct? To do this you need to use

To determine which of the conductors is phase and which is neutral using an indicator screwdriver, you need to touch its tip to the uninsulated part of the wire. If the LED lights up, it means that a phase conductor has been touched. After touching the neutral wire with a screwdriver, there will be no glowing effect.

The importance of color marking of conductors and strict adherence to the rules of its use will significantly reduce the time of installation work and troubleshooting of electrical equipment, while ignoring these basic requirements results in a health risk.