Free calculator to calculate the number of boards and joists required to lay the floor in a room with a given area.

Calculator features

The calculator performs the following actions and calculations:

- Calculates the area of the room;

- Offers optimal sizes boards and logs for laying floors;

- Calculates the optimal distance between lags;

- Calculates the volume of lumber and insulation that can be laid under the floor;

- Draws an approximate diagram of laying the future floor.

Features of working with the calculator

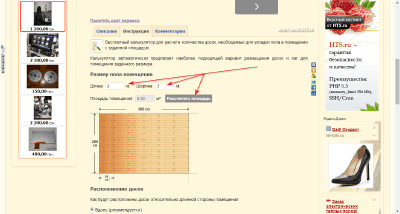

For preliminary calculations, just enter the length and width of the room in the special fields, and then click the “Calculate area” button:

Based on the data you entered, the script calculates the number and sizes of boards (taking into account the choice of the minimum standard width for laying end-to-end and proportional thickness), as well as load-bearing joists.

Based on the calculations, the calculator draws an approximate diagram of the future floor installation. On the diagram, callouts indicate the length and width of the room, as well as the recommended gap between the joists, which are indicated by a dotted line.

If in the "Length" field you enter a number greater than in the "Width" field, the values will be swapped, taking into account the fact that the length is always the larger side of the room.

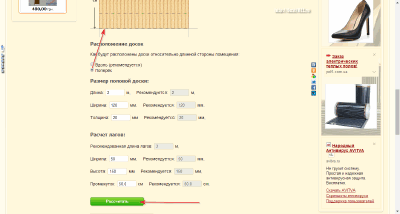

If you are not satisfied with the proposed automatically calculated parameters, you can always correct them using the input fields under the drawing:

Here it is possible to switch the direction of laying the floor to the transverse option, and there are also two sections with settings for the parameters of the boards and joists. To complete the calculations, you need to click the "Calculate" button under the input fields.

The results will open in a new browser window:

Integrating the script into other sites

* Provided that you provide an active dofollow link to our page.If you liked our script, you can install it on your website *.

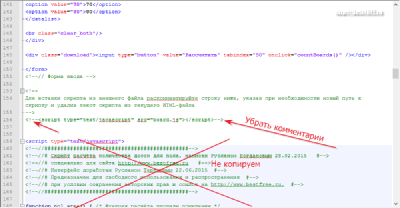

In the downloaded archive you will find two files: board.html And board.js. The first contains full code calculation forms and built-in processing script. In the second, only the script is included in case of external connection.

If you do not plan to connect the script externally, you can simply copy the contents of board.html and paste it onto the desired page of your site. Otherwise, you will need to copy only the part of the code before the start of the script and uncomment the line for external connection:

P.S. Permission is granted to freely copy and quote this article, provided that an open active link to the source is indicated and the authorship of Ruslan Tertyshny is preserved.

The following unique calculator is used to convert exotic units of length to...

Next online calculator about pounds. Previously it was very popular...

The following online calculator can calculate the liquid level in a cylindrical container...

The following online calculator converts temperatures between different scales. Remember the calculator...

The next calculator is interesting because it converts ancient Russian monetary...

The following calculator will be very useful for those who decide to buy or...

The following calculator works very simply, you only need to enter one...

The following online calculator calculates human height using the Russian system of measures...

The following online calculator can calculate the screen dimensions of TVs, computers, projectors,…

There are 2 calculators in front of you: one will help you choose the photo format...

The following 2 calculators convert a given number of tiles to square meters...

Here are 2 online calculators. They convert measures of area from metric...

The following unusual calculator converts length measures from the Russian system to...

Here are 2 calculators that are designed to convert length measures...

The following simple calculator converts your entered toC from Kelvin to...

The following calculator is for converting kg to pounds. There is also…

When carrying out a wide variety of work - from full-scale construction to reconstruction, redevelopment, finishing and much more, this type of material such as board is widely used. And before you go to the store, you should calculate the cubic capacity of the boards, this is necessary for the simple reason that all sellers sell the material in this particular measurement system.

We will consider exactly this stage, when you take all the necessary measurements and calculate the approximate volume of materials, this will help you cope with this process much faster and get the maximum exact result.

Important nuances

To ensure that the cubic capacity of the board is calculated efficiently, follow a few simple recommendations:

- Accuracy - you can’t estimate the area by eye; most likely, your eye will let you down, and in the end you will buy either too much or too little material. Use a tape measure, even if you don’t have one, you can buy one - this measuring device will be needed more than once, and its price is low;

- Structuring information, you should not rely on memory, if you are making several measurements, it is easier to make a simple list and record all the results in it, this will simplify the work and eliminate errors and omissions;

- It is important to choose the optimal type of material; for example, if you are calculating a floorboard, then without knowing its thickness, you will not be able to calculate the pitch of the joists. Likewise in other cases, the use of unreliable elements will lead to a decrease in strength, and the use of too massive ones will lead to additional load on the structure;

- Also, decide in advance on the breed and grade of the option you need; the cost of materials largely depends on this, but if you do the work yourself, then it’s better not to save on it.

Features of calculations

We will divide all work into two large groups - calculations of materials for use in various designs and calculations of finishing elements, these are separate product groups, so they have differences.

Use in various designs

Of course, you can find a calculator online for calculating the cubic capacity of boards, but the process is so simple that it is better to figure it out yourself; this will allow you to navigate the work much better and understand the features of each of them.

Instructions for performing calculations are as follows:

- The first thing you should learn is the formula for calculating the cubic capacity of a board, it is very simple: length multiplied by width and height, all indicators are taken in meters. This way you can calculate the volume of a single element and, knowing this indicator, you can calculate the total quantity in cubic meters;

- Calculating boards in a cube is very simple - the number 1 is divided by the volume of one product you received.. As you can see, everything is elementary and simple, and it is impossible to confuse the indicators, since there are only two of them. In order to further simplify the process and speed it up, below is a table for calculating boards in a cube;

| Board size | Quantity per cubic meter, pieces |

| 20x100x6000 | 83 |

| 20x200x6000 | 41 |

| 25x100x6000 | 67 |

| 25x150x6000 | 44 |

| 25x200x6000 | 33 |

| 30x100x6000 | 55 |

| 30x180x6000 | 30 |

| 30x200x6000 | 27 |

| 40x100x6000 | 41 |

| 40x200x6000 | 20 |

| 40x250x6000 | 16 |

| 50x100x6000 | 33 |

| 50x200x6000 | 16 |

| 50x250x6000 | 13 |

The data is rounded to whole numbers in the same way as manufacturers and sellers do. Of course, there are many more standard sizes, and we have presented the most popular ones. If necessary, you can calculate the boards yourself - it’s not difficult to determine how many in a cube, it will only take a few minutes.

Advice!

If you use an online calculator, then the importance of correct measurements and choosing the desired material thickness increases even more.

- When calculating materials, it is important to know exactly the area they will cover, if the sheathing is being done, then the elements are arranged at intervals, therefore, this factor must also be taken into account without fail.

This is how elements are calculated for the construction of a roofing system, various sheathing, subfloors, decking and much more; most often it is used for all these works. edged board normal humidity or dried, thickness can vary over a fairly wide range - from 16 to 50 mm.

Elements for finishing

This includes all types of boards that are used for finishing coatings, among which there are several main options:

- Specially profiled ones are a block house, imitation timber, lining and much more; essentially it is a board, the surface of which is given a certain shape, and a connection system is made at the ends for high-quality joining. It is much easier to count all such products, since they are sold in square meters, and you only need to measure the area to be covered;

Advice!

Always take this kind of material with a small margin, since some elements will be cut and it is not a fact that the pieces will be able to be adapted somewhere later.

- Deck and deck boards are most often made from larch, as this material is resistant to weathering and humidity. The calculation is made by area;

- The floor board is also measured by quadrature, but here it is important to take into account some nuances: how the board will be positioned, how many joints will be on the surface and what the amount of waste will be. In order not to make mistakes in this important process, we recommend using a calculator for calculating boards for flooring; you can easily find a similar program on the Internet.

Conclusion

Lumber- wood products of established sizes and quality, having at least two plane-parallel layers.

Lumber is obtained as a result of longitudinal division of round timber (logs), as well as longitudinal and transverse division of the resulting parts.

Types of lumber

Depending on the orientation in the log:

- Radial sawn lumber is lumber obtained by oriented sawing of round timber or beams with a predominant direction of cuts, close to the radii of the annual layers of wood.

- Tangentially sawn lumber is lumber obtained by oriented sawing of round timber with a predominant direction of cuts tangential to the annual layers of wood.

Depending on the sawing of the edges, planing and calibration:

- Edged lumber - lumber with edges sawn perpendicular to the facets and with a wane not exceeding what is permissible according to the relevant regulatory and technical documentation (edged lumber can have parallel and non-parallel (along the run) edges).

- Single-edged lumber is lumber with one edge sawn perpendicular to the faces, and with wane on this edge no more than permissible in edged lumber.

Unedged lumber - lumber with unsawed or partially sawn edges, with a wane more than acceptable in edged lumber. - Planed lumber is lumber in which at least one face or both edges have been planed.

- Calibrated lumber is lumber that has been dried and processed to a specified size.

Depending on the guarantee of strength indicators: - Structural lumber - lumber with guaranteed strength indicators for the manufacture of parts of load-bearing structures.

Depending on the type of sorting:

- Machine-sorted lumber is structural lumber sorted using a mechanical device, the operation of which is based on the relationship between the modulus of elasticity and the ultimate strength in bending, tension, and compression.

- Visual sorting lumber - lumber sorted by external inspection based on the size, quantity, nature and location of wood defects.

Depending on the processing of the ends:

- Faceted - lumber cut to length.

- Uncut - lumber that has not been cut to length.

By assortment:

- Bar

- Board

- Sleepers

- Lagging

- Gorbyl