Enclosing structures made of corrugated sheets have gained popularity among consumers due to their strength, durability, presentability and affordability. But their performance properties largely depend on the quality of the supporting frame construction. The material for its manufacture must be resistant to loads, influences environment, easy to process and affordable. A profile pipe for a fence made of corrugated sheets has these characteristics.

Profile pipe- a construction metal product made from carbon or stainless steel. The product has a square or rectangular hole. It is made by deforming a round welded pipe using a cold or hot method. The cross-section is formed by applying special rolls to the product.

The following are usedpipes for fences(construction of supports, crossbars), construction of building frames, floors, installation of masts and other structures resistant to.

Benefits of use

When arranging a fence, it is important to know which pipes are better: profile or round. All aspects should be taken into account. Round products have greater resistance to mechanical load. Their cross-sectional shape provides the supports with maximum rigidity even with a small material thickness.

But profile pipes are much more convenient to install than their round counterparts. They have a flat surface, which makes them easier to cut, join, and fix..

Profiled pipes used to construct the frame of fences from corrugated sheets have the following advantages:

- high strength;

- long service life;

- speed, ease of installation;

- unpretentiousness in care;

- an extensive product range (they come in various lengths and sections);

- affordable price.

Important nuances: metal products have one drawback - they require additional processing. To reduce the risk of rusting, the product is coated with a special primer or galvanized. Also metal supports periodic painting is required.

Features of choosing pipes for supports and frame of the fence

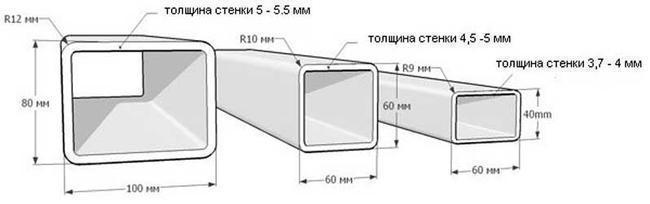

Standard profile pipes are produced with a cross section from 10x10 to 500x400 mm. The wall thickness of the product is 1-22 mm. The length of the pipe can vary from 6 to 8 m.

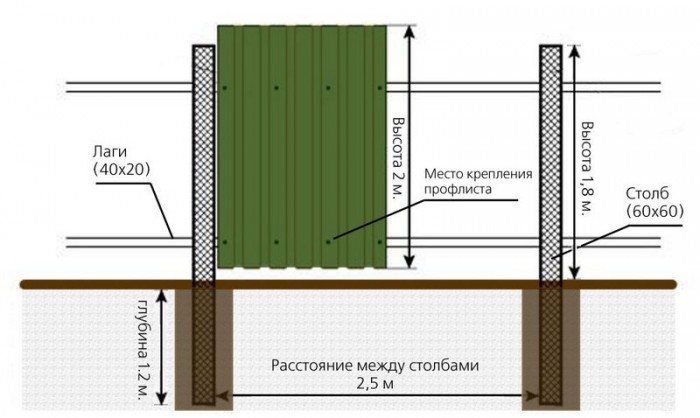

Posts for fences made of corrugated sheets are selected taking into account the height of the structure, the width of the sections and the planned load (for example, gusts of wind). For a fence with a height of 1.8-2.2 m, a support with a hole of 80x80 mm would be a suitable option. In this case, the wall thickness of the profile pipe should be 3 mm.

For a fence reaching up to 1.5 m in height, there is a square 2-mm corrugated pipe measuring 40x40 or 60x60 mm. It is also possible to use a rectangular product with a 30x20 or 40x20 mm hole of similar thickness.

Please note: the spacing of the supports is also important. Optimally, it is 2.5 m. If gusty winds are often observed in the area where the fence is laid, the posts should be installed 2 m from each other.

Cost of professional pipes

Since there are many manufacturers of steel pipes and a fairly extensive range of products, before construction it would be good to find out the price range for this material on the construction market. This will allow you to calculate the cost of the enclosing structure and plan the budget for its construction.

To do this, you need to know which pipe will be used and how much of it will be needed. The first indicator is determined based on the dimensions of the fence, and to establish the second it is necessary to calculate the total footage of all supports and crossbars of the structure according to the drawn up drawing.

Advice: it is most convenient to make calculations for 1 m. item of the product.

The cost of rectangular corrugated pipes with a cross-section of 40x60 mm and a thickness of 2 mm averages 110-120 rubles/m. st. Stronger racks 80x80x3 mm will cost 260-290 rubles/m. p., and pillars 100x100x3 mm - from 360 rub./m. p.

For horizontal fence crossbars, small cross-section pipes are used. They evenly distribute the weight of the facing material (corrugated sheet), transferring it to the supports.

For a 2-meter fence there are pipes 40x20x2 mm, which cost 66-74 rubles/m. n. When constructing higher and more massive fences, a profile of 60x30x2.5 mm is used, which will cost 95 rubles/m. p.

Technological aspects of installing supports and frames for fencing

After drawing up a drawing of the fence, determining which pipe section is best to use, and purchasing materials, we begin to install the structure. First, the racks are installed. To do this, they pre-clean, level the area for the fence, and make markings.

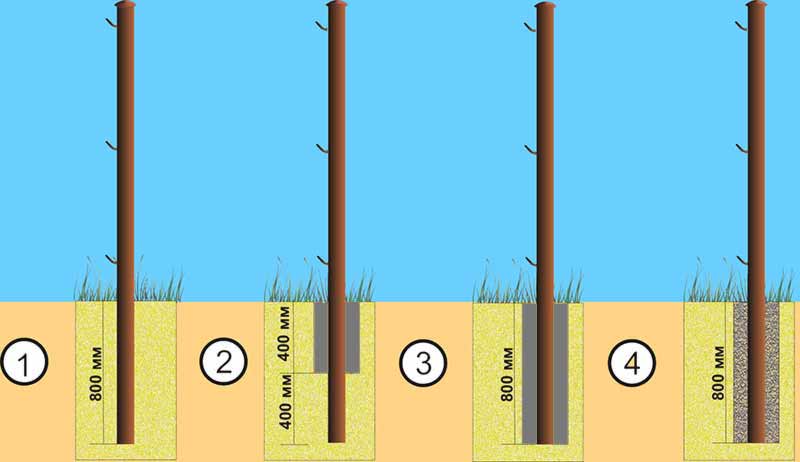

Installation of corrugated pipe posts on a fence can be done in several ways:

- by driving into the ground. The support is deepened into the ground by 1/3 of its length using blows with a sledgehammer. This method of laying the foundation for a fence is used on lightly rocky soils. The negative aspects of its use are the risk of damage to the support, unevenness of its installation, insufficient fixation;

- using backfilling and compaction. The pillars are laid in a dug/drilled shaft and then fixed using gravel-sand backfill;

- partial concreting. The lower part of the support is poured with concrete, and the rest is covered with earth, followed by compaction;

- complete pouring of concrete.

Note: the last option is the most reliable, since it provides the best fixation of the pillars. Other methods may be ineffective due to soil instability (wetness, drying out, freezing), which will lead to deformation of the fence.

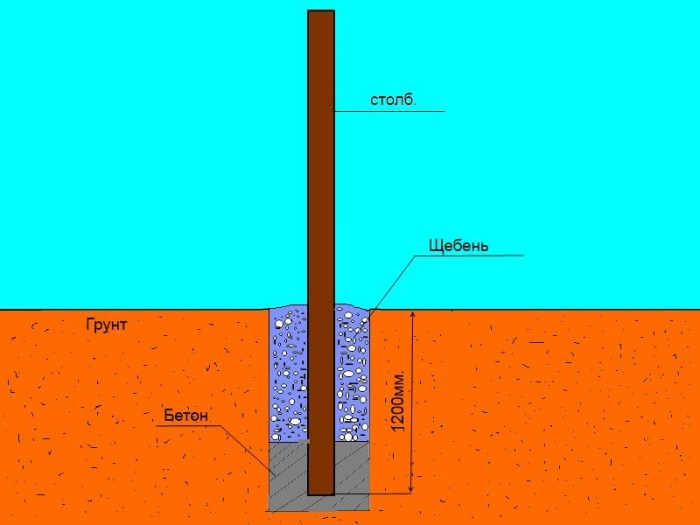

First, holes of the required depth are dug under the supports. The support must be deepened into soft soil by at least 1.2 m, into dense soil by 0.8-0.9 m. The bottom of the holes must be filled with sand and crushed stone mixture to ensure drainage. After this, the pillars are installed in the recess, leveled and filled with concrete.

Remember: racks made of rectangular corrugated pipe must be mounted with the narrow side facing the fence cladding. This will increase the structure's resistance to wind loads.

Installation of logs

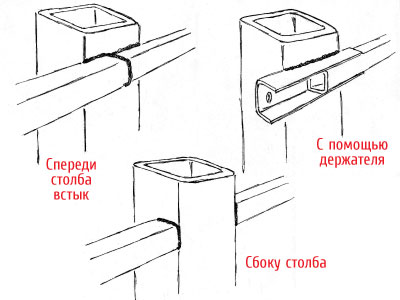

The crossbars used to fasten corrugated sheets can be installed in several ways:

- overlap The logs are laid on top of the pillars and fixed by welding or self-tapping screws;

- end-to-end The crossbars are attached to the posts by welding with a T-joint (T-shape);

- in the slot. Slots are made in the vertical support at the bottom and top through which the logs will pass. The fence crossbars are fastened using welding.

Note: a fence made of corrugated sheets on a frame and supports made of corrugated pipes is not afraid of strong winds, because the structure has increased strength.

The strength of the fence, its resistance to environmental influences, and other operational characteristics largely depend on the quality of the structure’s construction. Supports and cross members made of corrugated pipes can significantly increase the reliability of the fence, its durability, and extend its service life.

Metal pipes for fences have many advantages: durability; increased strength; It is convenient to attach sections and individual elements of the fence sheet, in particular, logs, to such supports. In addition, in comparison with concrete analogues, a metal pipe for a fence is characterized by a fairly low weight. You can also attach sections made of any material to such support posts: wood, mesh, corrugated sheets, plastic.

Design features

Metal pipes for a fence installed on a private residential site or country house are divided into two key groups:

- with round section;

- profile products.

In turn, the second option is more often found in two designs: square, rectangular pipes metal for the fence. Round pillars are more suitable for structures such as mesh fencing (made of chain-link and welded material). In this case, fastening is carried out using metal hooks installed by welding on the intake pipes. This solution allows you to increase the tension of the mesh material.

Profile analogues are usually used when installing profiled sheets and metal picket fences. This option can be equipped with embedded parts, which greatly simplify the task of installing the fence, in particular, attaching the logs. Intake pipes are sometimes offered with protective elements at the end sections. This reduces the likelihood of moisture penetrating into the product.

Pipe length: how to choose?

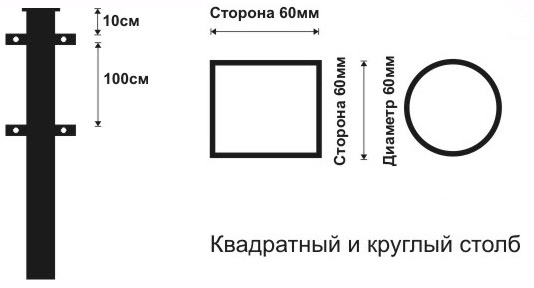

Metal pipes for the fence are placed quite deep underground: from half a meter to 1.5 m. Different requirements are imposed on the above-ground and buried parts.

When installing a fence made of corrugated sheets with a height of 2 meters, it is necessary to choose a length of at least 3 meters.

The protruding section of the support can be lower than the upper edge of the fence sheet only when it is used as reinforcement for a stone or brick pillar.

When constructing a fence around a private house or at a dacha from corrugated sheets, mesh, or forged sections, the metal intake pipe must be flush with the top edge of the structure’s filling. Accordingly, in this case, the support posts will rise above the joists, if they are provided.

A metal pipe for the fence can be installed in the soil to a depth slightly exceeding the boundary of the watery layer. In this case, the location of the support post should be deep (1.5 m), it all depends on the characteristics of the soil in a particular area. If the watery layers are low, then it is advisable to install posts under the fence at the dacha no deeper than 1 m.

For the lightest structures, it is enough to prepare holes up to 0.5 m deep. Accordingly, a metal pipe for a fence can have a total length of 4 to 2 m, it all depends on the structure of the soil, as well as the height of the fence.

Section selection

The degree of strength of the material under the supporting pillars is determined by the level of loads exerted: the higher they are, the larger the cross-section of the pillar should be. The preferred thickness of the product depends on this factor.

A metal pipe for a fence can be round, square or rectangular; accordingly, the level of reliability directly depends on the shape. For example, profile products have stiffening ribs that make them more resistant to loads. This means that this type of support is chosen for heavy structures.

A metal pipe for a fence can be round, square or rectangular; accordingly, the level of reliability directly depends on the shape. For example, profile products have stiffening ribs that make them more resistant to loads. This means that this type of support is chosen for heavy structures.

A metal pipe for a fence can have a wall length from 40 to 100 mm. The diameters of round products are in the same range. For structures with increased windage, it is recommended to choose materials for fence posts with a minimum cross-section of 60x60 mm. It is preferable to build the heaviest fences in the country using 80x80 mm and 100x100 mm posts.

As for the wall thickness of the pillars, the preferred values are 2.5 mm and 3 mm for structures of medium and heavy weight. Lightweight fences are mounted using pipes with a wall thickness of 2 mm.

Determination of cost

On average, a metal pipe for a fence is offered at a price of 130 rubles. up to 700 rub. per linear m. The most affordable products are characterized by a small wall thickness (2 mm) and cross-section (60x30 mm).

The main characteristic that influences the life of a metal pole is the wall thickness. This indicator is also related to cost, because The weight of the metal and its price are directly proportional indicators.

Accordingly, the most expensive pipes (3 mm, 100x100 mm) can be purchased for 450 rubles/linear. m. If we consider even more reliable products (4 mm, 120x120 mm), its cost reaches 700 rubles/linear. m.

How to protect a product from corrosion?

To solve this problem use different ways, which together allow you to extend the service life of the finished structure:

- Anti-corrosion compounds and paints and varnishes. If you plan to build a fence at your dacha on your own, you need to carefully choose metal materials. It is recommended to purchase products for pillars without finishing, i.e. without coating with paint. It is enough to buy pipes coated with a primer. This need is explained by the fact that the paint gets scratched during transportation and during operation.

- A top is installed on the post. This decorative element, which additionally performs another function - it protects the support post from moisture penetration into the internal cavity.

Metal pipes are also often used, in which the lower end is welded and installed in the soil. All these measures help to increase the material’s resistance to rust formation when in contact with water. If you purchased an unprotected metal pole, you need to take care of covering it yourself with a primer and paint, and it is advisable to apply 2 layers of material.

For heavy fencing, a more durable material is suitable - pipes with a cross-section of 80x80 mm and higher with a wall thickness of 3 mm. Middle option fence requires the use of posts with a cross-section of 60x60 mm or more, the thickness of the material is 2.5 mm. Lightweight fences are erected using pipes of minimal cross-section (from 40x40 mm and above, wall thickness 2 mm).

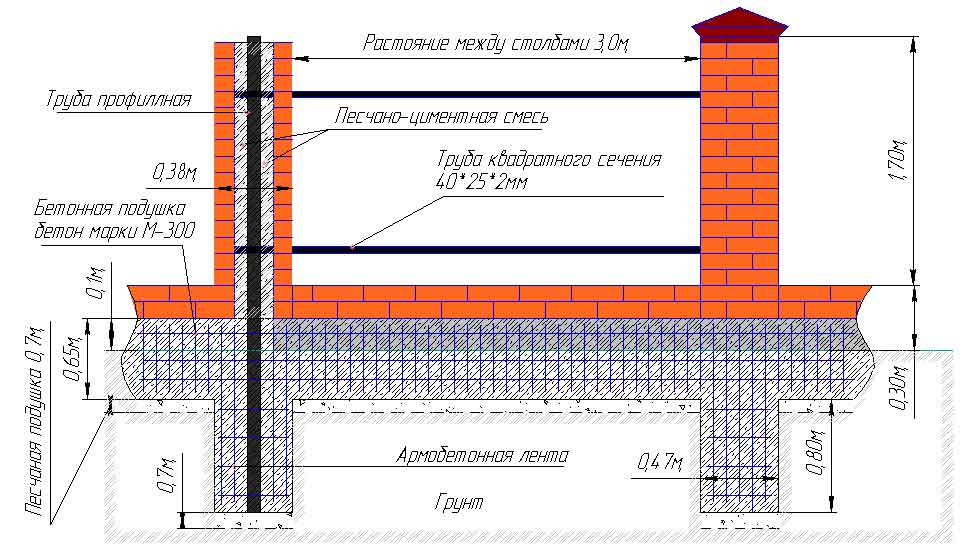

Installing a fence made of corrugated sheets has a number of features that distinguish this process from the construction of other types of fences. Despite the relatively light weight of the base material, such a fence requires reinforcement of the frame structure. This is due to the so-called “sail effect”: a solid wall made of corrugated sheets will have to withstand strong gusts of wind. To avoid bends and distortions of the fence perform the following operations:

- holes for support pillars or a trench for the foundation are made deeper than the freezing level of the soil - optimal: 1.2-1.5 m;

- support pillars are selected about 2 m high(above ground level);

- they assemble the frame not from two, but from three transverse joists;

- the logs are welded in such a way that when installing the corrugated sheet, each of the pipes (including the pillars) comes into contact with one of its sides with the profiled sheet;

- profiles are used as support pillars pipes with rectangular or square cross-section, instead of round.

Profile pipe

Just a few decades ago, round metal pipes were used as support posts in the construction of fences. Now the situation has completely changed in favor of profile pipes with a “square” or “rectangle” cross-section. This is not surprising, since the surface of a post with a profile rectangular cross-section, in contact with the flooring sheet, occupies a larger area (compared to a round one). This ensures improved structural stability.

Profile pipes are available in various sizes and with different wall thicknesses. For a fence made of corrugated sheets, you need to select pipes no less than 60×60 mm(square section) or 60×40 mm(rectangular section). Wall thickness - from 3 mm.

The required pole length consists of its height above the ground level and the “underground part” in the foundation. For example, if the depth of the foundation is 1.3 m and the height of the fence is 1.7 m, then the length of the pipe for one pillar is 3 m.

They produce profile pipes immeasurable length or measured from 4 to 12 m.

Lags

The ideal log is a profile pipe with wall thickness 2.5 mm and rectangular cross-section from 40×20 mm. The logs are welded in such a way that the corrugated sheet is mounted on their wide side. The log length is calculated according to the distance between the support pillars plus a small tolerance- for welding work.

Since pipes are made from standard length, you will have to determine the required size of the log and cut the profile on your own.

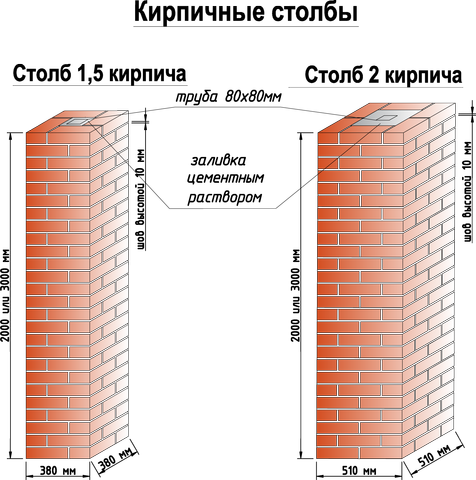

Brick support pillars

When erecting a fence made of corrugated sheets with brick support pillars, it is necessary to install profile pipes at their locations 60×60 mm or 60×40 mm, pour a concrete foundation depth from 1 m and then do brickwork.

Any facing brick is suitable for this purpose. You can also save money by laying out only the outer row as facing, and using a regular row inside the pillar. Sand-lime brick heavier than ceramic, so the stability of a support made of such material will be slightly greater.

Components and accessories

End top bar

The upper end of the fence made of corrugated board is optionally decorated with a corner or U-shaped edge strip. Basically, the planks are made from standard sizes and fixed footage. The plank is mounted using self-tapping screws (roofing or plasterboard profile).

Pole plug

Flat plastic caps for poles perform not only a decorative function, but also a protective one. Moisture, dirt and dust will not get into the “closed” pipes, which means the pole will last much longer. The size range corresponds to the pipe profile.

Cap for brick pillar

Metal simple and openwork forged caps for pillars will protect the brickwork from moisture getting inside, preserve its integrity, and also create a visual effect of completeness of the fence design. Available in various sizes: 500×500, 500×400, 400×400, wall thickness 0.5 mm.

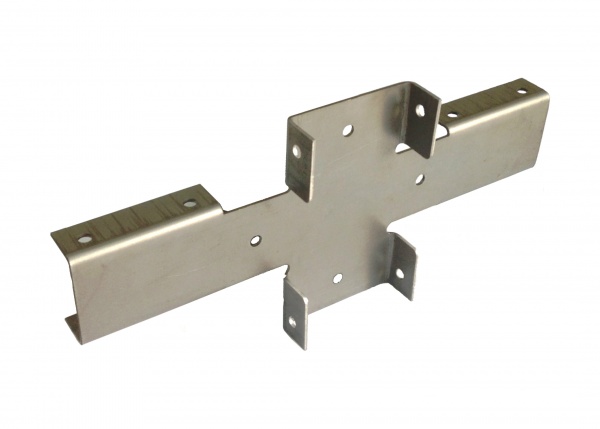

X-bracket

If the logs are attached to the poles without welding, X-brackets will greatly simplify installation. With their help, the right angle during connection will be maintained with extreme precision, and the process of fixing the jumpers will be much faster.

Frames for swing gates and gates

Gates and wickets can also be made from corrugated sheets. To do this, you need frames onto which the sheet will be “sewn.” Manufacturing material: profile pipe 40×20 mm.

Approximate dimensions of structures

- for gates: height - 1.8-2 m, width - 0.8-1.2 m;

- for gates: height - 1.5-2 m, width - 3-4 m.

And finally, advice on installing support pillars.

If a crosspiece made of reinforcement is welded to the bottom of the pipe, and a metal plate up to 50 cm long is welded at a level closer to the ground surface perpendicular to the future fence, then the post will receive additional supports and the fence will receive reliable stability.

Message

sent.

Fence made of corrugated sheets - profitable installation order What do you need to know when buying corrugated sheeting for a fence?

When installing a fence made of corrugated sheets, mainly two types of pipes are used:

- pipes with a classic round cross-section, or profile ones, which are installed as vertical supports;

- a cut square or rectangular section of pipe for installing horizontal joists.

Thus, when installing a fence made of pipes, you can save significantly by using different pipe thicknesses. For pillars, larger pipes are purchased compared to thin-walled logs.

When installing a fence whose height exceeds 2 m, a pipe with a diameter of 80 mm is used as posts, and if a fence of 2 meters or lower is planned, a pipe with a diameter of 60 mm is used.

Due to their high cost, round pipes are very rarely used for fences. They mainly use profile material with the following parameters:

- 80mm * 60 mm – for fences more than 2 meters high;

- 60mm * 40 mm – for fencing 2 meters and below.

The number of supports required when installing a fence is calculated along the perimeter of the fence. We divide the footage by the pitch (the distance between the pillars) and get the required number. Professionals recommend using a step of 2 meters. The length of the post is taken to be 30% greater than the planned height of the fence. This is the size of the part of the pipe that will be installed underground.

To connect the pillars, use a profile pipe cut in half, so it is easier to attach the fence panel to it than to a round one. For these purposes, take a pipe with dimensions of 20mm * 40mm, for any fence height. When installing a fence up to 2 m high, two logs are installed between the supports, and for a higher value - three. This is due to the fact that the corrugated sheet can bend under the influence of the wind. Depending on the desired height, the number of horizontal elements is also calculated - the perimeter of the fence is multiplied by two or three.

Installation of vertical supports

Builders use four methods of installing a pipe for intake into the ground:

- You can use a drill to drill a shaft of the required length and immerse a vertical support into it. Concrete mortar is used to fix the pipe. Disadvantage this method is the time it takes for concrete to harden;

- You can use fine gravel as a filler in the prepared trench and stuff a pipe into it. Only the stability of such a support will be questionable;

- You can weld a drill string with blades to the end of the pipe and screw this structure into the ground. This is a very effective but expensive way to install fence posts;

- the support can simply be driven into the ground; only with this technology is it possible to damage the outer end of the pipe and cause the column to deviate from the vertical.

The height of the supports is controlled by a hydraulic level, the step distance is controlled by a measuring rope, which is pulled between the columns.

Installation of horizontal joists

There are three methods for installing logs on installed vertical posts:

- overlap fixation - a horizontal frame element is welded or screwed to a vertical support;

- butt installation - the logs are welded to the rack, forming a T-joint. This method is not applicable for round posts;

- using cut grooves - a special groove is made in the column into which logs are installed. The elements are fastened together by welding.

Sheets of corrugated sheets are attached to the fence frame installed from pipes with self-tapping screws along the entire perimeter. The installation of sheets begins from any pillar and the height of the boards is controlled by the adjacent sheet.

Add to bookmarks

Installation metal pipes when building a fence from corrugated sheets

Recently, fences made of corrugated sheets have increasingly begun to be installed for fencing industrial, commercial and construction sites, and for fencing private land and household plots. This popularity is due to the availability of materials, simplicity and relatively high speed of construction of this type of fence. What materials are best to use when building such a fence with your own hands?

One of the most important parts of corrugated sheet fencing are the support posts, which are most often made from round or profiled pipes.

How should pipe columns be installed so that they securely and firmly hold the entire fence structure?

Required materials and tools

Methods for installing fence posts: 1. Driving the posts into the ground, 2. Partial concreting of the fence post, 3. Full concreting, 4. Tamping (ramming) with crushed stone.

The main material, naturally, is a round metal (preferably steel) pipe or a profiled version of it. A round pipe is more suitable for fences made of corrugated sheets, in which through gaps are provided between the sheets of the latter, where the columns will be located. The profile pipe is used in the construction of a continuous fencing sheet. The diameter of the round pipe should start from 6 cm, and the width of the metal profile - from 4-5 cm. You will also need a tool for cutting pipes: manual (hacksaw, pipe cutter, etc.) or special (electric welding or gas cutter). An electric welding injector machine will also be needed to attach other metal parts of the fence to the columns. In addition, you will need a tool for digging trenches and holes under the foundation, for mixing cement mortar (shovels, mortar containers, electric mortar mixer, etc.).

Calculation of the required length and number of pillars

To build a fence with your own hands, you first need to calculate its length, from which to base your calculations required quantity columns. In regions where hurricane gusty winds do not occur, the columns can be placed at a distance of 3 m from each other. If you need to strengthen the fence structure with your own hands, this distance can be reduced down to 2 m. It should be understood that a continuous fence made of corrugated sheets has a high windage coefficient, and therefore you should not save too much on materials. The strength and integrity of the future structure depends on their quality and correct installation.

Considering the average height of the fence (about 2 m) and the depth of the ground (about 1 m), the length of each post should be about 3 m. Thus, you can purchase standard 6-meter pipes and cut them in half. It should also be taken into account that when constructing a fence from corrugated sheets with your own hands, you can use thinner metal profiled pipes as longitudinal strips to which the sheet material will be attached. It is also very easy to calculate the required length of this metal profile, knowing how long the entire fence will be.

Digging and installing pipe columns

What depth of digging metal columns into the ground is needed in a particular area depends on the strength of the winds in a particular region. However, it can be argued that a meter depth in the ground will be quite sufficient. Corrugated fencing is best done on a cement foundation. Therefore, installing a fence yourself should begin with digging a trench for the foundation and installing formwork. Where the metal columns are installed, the foundation needs to be slightly expanded to form square bases for them. The columns must be installed along a stretched cord to ensure an even and straight plane of the future fencing fabric.

After digging the pipes into the recess, the internal cavity of the formwork is filled with cement mortar. In this case, it is necessary to first maintain the column in an even vertical position by eye, and then accurately level it using a level. Cement mortar must be of high quality, because the entire fence will be supported by these columns. After installing and aligning the latter, longitudinal strips can be attached to them. When metal pipes are used, they are welded using electric welding.

After installing the metal columns holding the fence, they must be properly treated to protect them from corrosion. For this, either a special protective primer or water-based anti-corrosion paint is used. Firmly installed metal posts will be a reliable guarantee that the corrugated fence will be reliable and durable.