Before understanding the intricacies of building fences, let’s find out what a metal profile is. Metal fence profiles are bent steel sheets with wavy or trapezoidal corrugations. They are produced on special roll forming machines and used in construction and other economic fields.

Metal profile is an ideal material for building a fence

The most common application. But why is corrugated sheeting used for them?

Metal fences made from corrugated sheets are high-quality and durable structures that can be erected in a short time. Thanks to the “opacity” of the material, you can easily isolate your area from unwanted eyes.

The price of metal profiles is quite low, which makes the material affordable and attractive even for the average client.

Pay attention! In order to build a fence from a metal profile, you do not need to have a construction education or special qualifications. You just need to refer to our instructions and watch a couple of video materials.

Production

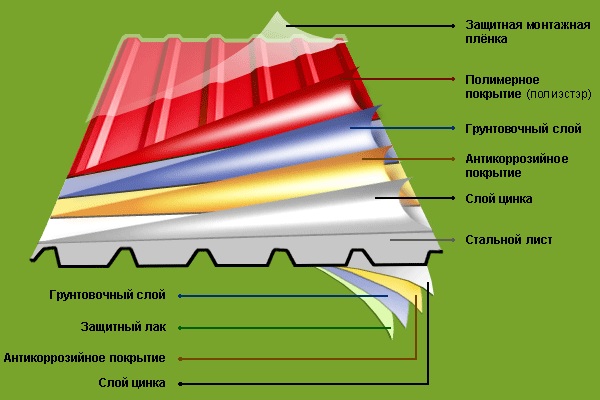

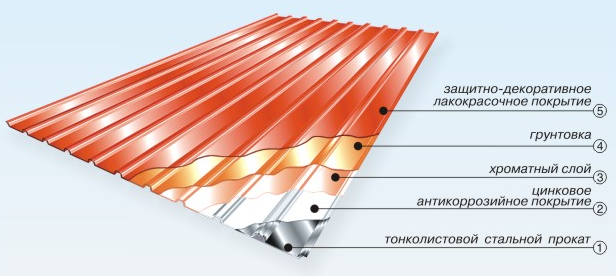

For the production of metal profiles, galvanized steel is used in accordance with GOST R 52246-2004, GOST 14918-80, EN 10326, EN 10147, as well as steel with a polyester polymer coating, which is applied by the roller method in special continuous operation units.

What is a polymer coating? At its core, it is a film that is formed using high-molecular compounds on the surface of rolled sheet steel.

The coating is formed by hot drying and applying paint and varnish materials (protective enamels, primers, etc.) using the roller method. Thanks to painting, steel becomes more protected from climatic and physical-mechanical damage, and also has excellent decorative properties.

Why do many of our fellow citizens choose a metal fence?

There are several reasons for this:

- Optimal price-quality ratio;

- Ease and speed of installation;

- Attractive, without spoiling the landscape, appearance products;

- Safety of operation and durability of the material;

- Possibility to combine with various types pillars (metal, stone, brick).

When purchasing corrugated sheeting, experts recommend purchasing from the same store:

- Spray paint in the same color as the profile;

- Self-tapping screws for metal;

- Veins and pillars;

- The tool you are missing for fence installation work.

Complete set of metal profile fence

If you thought that installation required only poles and corrugated sheets, you were deeply mistaken.

Now let's look at a detailed list of components for the new fence:

- Pillars are 60x60 mm, the length of which is at least 3 m. The pipe can be ordered already cut, with a plug welded (in the upper part), which will protect the posts from excess moisture and other precipitation.

Attention! It should be remembered that before installing the pillars, they must first be primed.

- The veins are metal crossbars 20×40 mm and about 3 m long. They are made of profile pipe and also primed;

- Corrugated sheets - you can order sheets of any length, color, polymer-coated or galvanized (see photo);

- Self-tapping screws for metal - here you can make the choice yourself. In most cases, specialists use self-tapping screws with a cross-section of 4.0×80 mm (hats to match the color of the corrugated sheet);

- Fence strip - made with your own hands from the same corrugated sheet. Necessary to give your fence a shape and a finished look;

- If your fence will have brick pillars, then you should purchase masonry bricks and special caps mounted on the “tops” of the pillars in advance;

- Bulk materials: sand, cement, crushed stone.

In order to produce a high-quality fence with rigid design characteristics, we recommend that you familiarize yourself with the following diagram:

- Installation of gates and gates made of corrugated sheets includes the installation of additional posts and wires;

- Installation of posts and veins of non-standard sizes;

Neat and harmonious fencing made of corrugated sheets, brick posts and steel caps

In order for fences made of metal profiles (no matter where you erect them) to last a long time, when installing them you should follow some recommendations, which we will now introduce you to:

- The first and perhaps the most important trick is correct installation pillars The step between them should not exceed a distance of 2.5 m. Experts recommend burying the pillars to a depth of 1200 mm, but here, too, it all depends on the type of soil on which your house (plot, dacha) is located;

- We attach the veins to the installed (compacted and filled with concrete) pillars using welding. To make the fence more reliable, it is recommended to weld 3 wires per section;

- Installation of corrugated sheets. The sheets are attached overlapping, on one wave. The recommended distance from the ground is 100-150 mm, since in the spring melt water has an adverse effect on the metal;

- Fastening of corrugated sheets is carried out using rivets or self-tapping screws. Builders recommend attaching corrugated sheeting through one wave (on average, you will need about 13-15 pieces per sheet). When using special metal screws, you do not need to pre-drill holes;

- After completing the main installation work To erect a fence, you need to install a special fence strip (purchased or made independently). Why is it needed? It is unlikely that you will be able to mount the fence in such a way that the top line is perfectly level - with the help of a fence strip this problem can be avoided.

In conclusion

If something doesn’t work out for you, then it’s better not to spoil it building material and seek help from friends or professional builders. Good luck!

Manufactured using profile pipes - profiles. The profile can have different shapes and thickness. The most commonly used in the manufacture of fences are rectangular and square profile pipes.

Since the profile is the basis metal fence, we can say as a fundamental part of it, the choice of pipe size must be approached carefully. The cost, type and characteristics of the future fence will depend on this.

Material selection

The most commonly used metal profile pipe with a cross section of 20×40 with a wall thickness of 2 or 1.5 millimeters. It can be used to make either an entire section of a welded fence or partially in combination with a smaller pipe, for example 20×20 or 15×15. Also, the 20×40 profile is used as a log for fences made of profile sheets. The strength of this pipe is quite sufficient for such structures.

A round or square profile pipe with a diameter of 60mm, 80mm or 100mm is used as pillars. The wall thickness of this metal should be 2 or more millimeters.

Profile sheet for fence

Sometimes a metal profile means corrugated sheet or profile sheet. When choosing this material, you should pay attention to the manufacturer. Quality products Magnitogorsk and Novolipetsk plants represent the domestic market. Learn more about sheets.

Nuances of choosing a metal profile for a fence

There are several main aspects in choosing a material for building a fence, and all of them are argued mainly by considerations of practicality and aesthetic appearance.

And the cost of the enclosing structure is the main indicator of the practicality and expediency of a particular category of fence. And the metal profile here is one of the most affordable materials in terms of cost and taking into account the complexity of installation.

Why metal profiles are so good for fencing

This material has the following undeniable advantages:

- Without repairs and reconstruction, corrugated sheets will last at least 10 years. But even after a small elimination of defects, after this period the durability of the metal profile will still be quite long.

- Textured resistance to deformation. Although the thickness of the material allows dents to occur, due to its structural features, they are easy to fix. And minor mechanical damage is invisible against the background of the wave structure of the metal profile.

- Fire resistance is ensured by the durable texture of the material.

- Resistance to climate change is another advantage of this type of fence.

The list of advantages also includes the availability of installation work and minimizing the number of additional elements. As a result, the justified low cost of a fence made of metal profiles.

Metal profile production

Main characteristics of the material

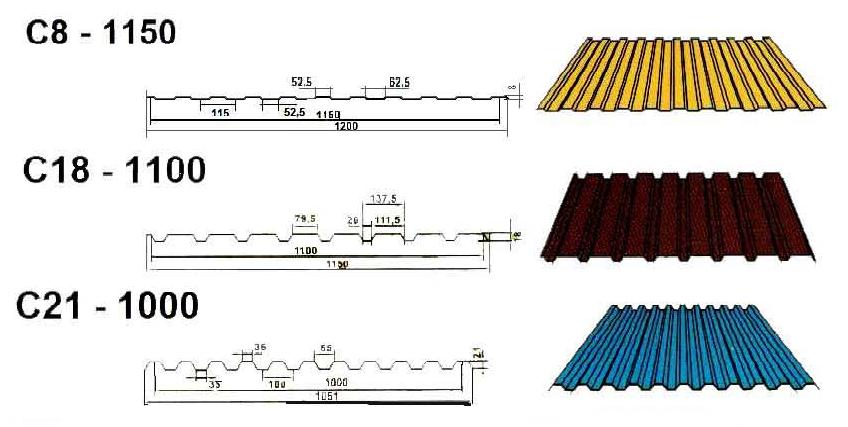

For the construction of fences from metal profiles, it is customary to use wall corrugated sheets, marked in the form of the letter C. In the category of this marking, the following three types of profiled sheets are accepted:

- C8– category of profiles in the form of a sheet of steel. This material has the appearance of a small-height trapezoid wave with a wide base. This structure of the material makes it the most economical of all three categories.

- S20– contains trapezoidal waves of greater height, which ensures sufficient structural rigidity. This material is somewhat more expensive.

- S21– the most durable category of metal profiles, with a high trapezoidal wave. Thanks to this, it has very high rigidity and excellent strength indicators.

At the same time, it is customary to distinguish between types of corrugated sheets based on the thickness and width of the steel.

The optimal option is considered to be a metal profile width of 0.5 mm, and a height, depending on the choice of strength, from 1.80 to 2.20 meters.

Another feature characteristic of fences made of metal profiles is the coating of the material. The most commonly used coatings are:

- Galvanizing treatment. Galvanization is the most budget option coatings and is most often used in the manufacture of profiles. The application technology is extremely simple - a zinc layer up to 30 microns thick is applied to a steel base. This is quite enough to protect the base material from corrosion, humidity, solar radiation and other external factors.

- Polymer coating made from synthetic resin compounds and plastics. Typically, this coating is used as an additional product applied over galvanizing. This coating method provides additional protective properties. In addition, the polymer coating, when pigment dyes are added to it, gives the profile a rich color range.

- Plastisol coating has the highest resistance even to significant mechanical stress. However, this coating also has disadvantages, the main one of which is sensitivity to elevated temperatures. When heated to 80 degrees, the technological qualities of this material are lost, so it is not used in hot climate zones.

Each of these coatings can improve the technological characteristics of the fence and prolong its durability. At the same time, appropriately processed metal profiles create a comfortable and cozy atmosphere in the territory of the summer cottage.

If you install a fence made of metal profiles with a high height - up to three meters, then it can serve as a reliable obstacle for robbers. It is almost impossible to climb over a fence with a perfectly smooth vertical surface.

Nuances of choosing a metal profile

The choice of material for fencing must be based on practical considerations, design and budgetary costs. First of all, it is necessary to calculate the load-bearing capacity of the entire structure. If you plan to install a reliable fence on the site as a means of protection, then you need to choose a more rigid material. Similarly, it is necessary to make a choice when constructing high fences - in this case, the priority property of the choice should be the strength of the material, so that deformation of the material does not occur during operation.

It's important to pay attention type and properties of the material. Since fences belong to the category of outdoor structures, inexpensive ferrous metal is not the best choice. It is not able to resist corrosion. At the same time, don't best choice will be copper or aluminum, although these materials are resistant to external influence. But compared to their advantages, they have a very high cost.

Therefore, only a steel fence profile can be a rational choice. Moreover, you should choose hot-dip galvanized steel - such a material will not be burdensome for the budget, and, at the same time, it has a long service life.

Sheet metal thickness– another important selection criterion related to pricing and practical profitability of the material. The thicker the sheet, the longer it will last and the higher its technological performance. But these advantages come with a higher cost.

In the photo - a fence made of metal profile

Focusing on the durability and practical functionality of the fence, you need to choose the degree of its security using outer covering. The thicker the coating layer, the higher the likelihood of long-term preservation of the properties of the fence.

Depending on the installation location, the purpose of the fence and the expected degree of exposure to aggressive factors, you must also choose one of the above-mentioned categories of corrugated sheets - C8, C20, C21.

In the video, what determines the price of corrugated sheeting:

Corrugated fences are found everywhere. The material is used for the construction of technical fences at construction sites, in industrial workshops, or for the construction of a permanent fence in a private house.

The popularity of this material is due to its technological qualities at an affordable price.

What is a metal profile

Metal profile - steel sheet. During production, the cold bending method is used. The steel used for manufacturing has a thickness of 0.45 to 3.75 mm.

During production, the sheets are cut into pieces. They are then coated with a layer of zinc or a zinc-aluminum alloy. The next stage of production is primer. And it all ends with the application of polymer to the surface of the product. This coating protects the steel from negative factors environment and attractiveness to her.

The color of the material depends on the customer's wishes. Due to special treatment, the service life of steel sheets is long. At correct use the profile design will last for decades.

What to look for

Color options for profile sheets

The construction market offers many types of corrugated sheets. To do right choice, the following parameters are taken into account:

- Strength of the material. This parameter determines the thickness of the sheet and the height of the corrugation.

- Resistance to negative factors. It consists of the number and type of protective layers.

- Appearance. The color of the profile should be combined with the general style of the site on which the fence is being built.

- To correctly calculate the number of sheets required for the construction of a fence, you need to take into account their sizes.

The best option is considered to be a type of corrugated sheeting that meets the requirements and has a low price.

Remember! When choosing a profiled sheet, you need to think about the quality of the substances used for production. Low-quality material loses its attractive appearance several years before the end of the service life promised by the manufacturer.

Types of material

There are several types of corrugated sheets available in construction stores. To build a fence, a wall profile sheet is used, which is designated by the letter C.

This variety is divided into subspecies:

- Profiled sheet C8. It has a large width and a low trapezoid wave. Thanks to this, the consumption of materials during the construction of the fence is reduced. C8 is one of the most economical types of wall profiled sheets.

- Profiled sheet C20. Has optimal parameters. Due to the height of the rib, such a sheet has sufficient rigidity, which simplifies the process of constructing a fence.

- Profiled sheet C21. Its wave has the greatest height, so this variety is the most durable.

Sometimes the metal profile markings contain additional letter indices. They are indicated after the wave height: C20A (B or K).

The letter A means that the profiled sheet on the front side is coated with polymer, painted in a color according to the RAL catalog. The letter B means double-sided coating, and K means the presence of an additional stiffener.

By type of coverage

The traditional option is zinc coating, it is the most economical. In this case, a thin layer of zinc is applied to the sheets.

Aluzinc can be used as a coating. This substance, consisting of 55% aluminum and 45% zinc, is capable of protecting steel sheets from the corrosion process.

Aluzinc contains a small proportion of silicon. Aluzinc coating gives the steel sheet greater durability compared to galvanizing, but the price of such material is higher.

To protect steel profiled sheets, it is not at all necessary to use exclusively metal. A protective layer of synthetic resins and plastics can be applied to the surface. This is a polymer coating that makes the material resistant to various influences. But the surface is still pre-treated with zinc. Pigments give the material a rich color.

The steel sheet can be protected with a layer of paint or varnish. This type of coating is characterized by ease of application, moisture resistance, multifunctionality, adhesion properties, and impact resistance.

By corrugation type

Wave-shaped material is common. This type of corrugated sheet looks similar to slate. Has good strength.

Another type of corrugation is often found - trapezoid. In fact, these are also waves, but their crests are not rounded, but are part of a trapezoid. This material is tough.

And another type of corrugation is called “cassette”. The profile of such sheets resembles the letters “P”.

Important! The shape of the corrugation and its height affect the strength of the corrugated sheet. The height forms a stiffener and provides resistance to wind loads.

Advantages and disadvantages

Profiled sheets are popular in the construction of fences for a reason.

The profile has the following advantages:

- light weight of each sheet and the structure as a whole.

- ease of working with the material. Installation is quick, and this work does not require complex expensive materials;

- sound insulation. Thanks to such a fence, you can protect yourself from extraneous sounds that interfere with your peaceful life. And the views of passers-by will also not interfere, since the canvas is continuous, without gaps;

- strength provided by waves;

- Corrugation resistance of the corrugated sheet. And additional substances applied to the surface only increase this stability, along with its service life.

The profile sheet has one drawback - artistic simplicity. It is difficult to build an original designer fence from it. However, this material can be combined with others - with rubble columns or forged inserts over the spans.

Types of fences

The design of the fencing structure is simple. It consists of a fence frame, support posts, crossbars for fastening and sections themselves made of metal profiles. In a standard fence, horizontal logs and supports are made of metal profile pipes.

In combined options, spans are created from corrugated sheets, and supporting elements are made from natural or artificial stone, brick or concrete block.

Modular fencing made of metal profiles is popular. The fence is convenient by installing ready-made sections into spans. This saves time, increases reliability and service life due to the anti-corrosion coating.

In modular fences, the corrugated sheet is attached to the frame like a construction set. The frame is made of zinc coated steel. The metal is painted with polymer paints, with a preliminary application of a protective adhesive layer. This gives them strength, reliability, durability and aesthetic appearance.

Conclusions

Any family can afford to install a fence made of corrugated sheets on their country property. This material is cheap and the process of constructing the fence itself is inexpensive.

The video material presented in this article will provide additional information on the topic.