For most private country houses comfortable conditions in winter time are provided not with centralized, but with autonomous heating. To operate it, electric, solid fuel and liquid fuel boilers are used, but the most popular option is gas equipment. The reason for this choice is high efficiency, automation of work and favorable energy prices. However, when using boilers, it is necessary to comply with the requirements for a gas boiler room in a private house, depending on the location of the equipment.

Rules for installing home boiler rooms

A separate building or even a room for a gas boiler is not required if its power does not exceed 30 kW. This simplifies the task of many private homeowners to accommodate heating equipment. Boilers can be placed in the kitchen, especially when it comes to wall models, occupying a minimum of space. However, this room is subject to no less requirements than separately located boiler rooms:

- The minimum kitchen volume is from 15 sq. m;

- room height – from 2.5 m;

- air exchange rate - from 3 to 5 room volumes per hour (for a kitchen with a volume of 15 cubic meters this is at least 45 cubic meters per hour);

- window glazing area – from 0.3 sq. m per 1 cubic. m of volume (for the same room this figure is 4.5 sq. m). The kitchen windows must have vents that are open when the boiler is operating.

Among the additional requirements for the kitchen in which the boiler is installed, we can note the presence of air intake holes under the door, ensuring air flow into the room. And the distance from gas equipment to flammable materials (wooden partitions and furniture) should not be less than 100 mm. If the boiler needs to be installed on an unsuitable enclosing structure, a metal sheet is placed between it and the partition.

Separate accommodation in a residential building

If the boiler power exceeds 30 kW, it is placed in a separate room, including basements, attics and attic floors. One of the prerequisites is a separate exit to the street and sufficient natural lighting. A to additional requirements the premises include:

- a volume of at least 7.5 cubic meters for boilers with a capacity of up to 30 kW, 13.5 cubic meters for models with a capacity of 30–60 kW and from 15 cubic meters for more powerful equipment;

- the possibility of convenient access to the boiler and its individual components;

- three-fold air exchange of supply and exhaust ventilation.

Heating equipment is located in such a boiler room at a sufficient distance from flammable surfaces. And the room itself is separated from other rooms by partitions and walls with fire resistance RE1 45. That is, by such structures that can protect from flames for 45 minutes.

Completely separate building

The advantage of a separately located boiler room is increased safety, reduced noise levels and saving space in a residential building. Disadvantages include increased costs for creating the system autonomous heating. Requirements for such boiler rooms include:

- the presence of a separate foundation not adjacent to the main building;

- separate base for a gas boiler;

- the height of the pedestal for the boiler above the floor is no more than 150 mm.

Only non-combustible materials should be used for the walls and roof of the boiler room. And a sewer pipe connected to the boiler must be connected to common system. With its help, the coolant is periodically drained from the pipes - it is recommended to completely replace this liquid at least once a year.

Features of doorways

Among the requirements for gas boiler houses there are also recommendations for arranging doors. For individual rooms inside the building, the door leaf and frame must be made of fire-resistant materials of class RE1 15. It is advisable to use metal for their manufacture - or buy ready-made metal structures.

For separately located boiler rooms, the doors, on the contrary, should be unsecured. Thanks to this, the energy of the blast wave will be directed to the door leaf and frame, and not to the walls. Another advantage of weak doors is the free passage of gas through them. Often, for this purpose, additional ventilation holes are made in the lower part of the door.

Ventilation requirements

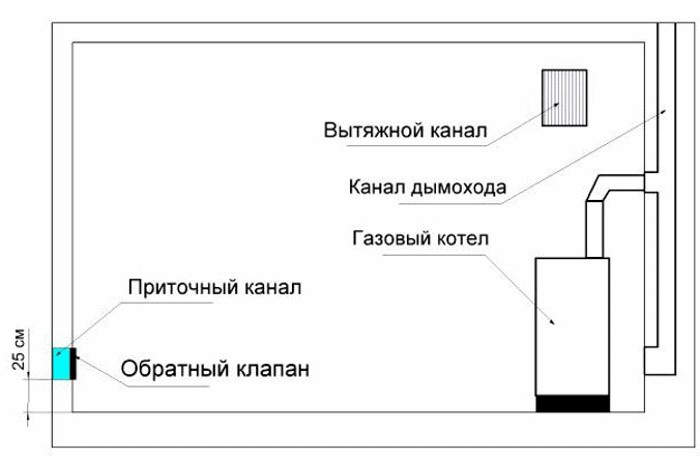

It is not difficult to provide natural ventilation for a small boiler. To do this you should:

- punch a hole with a diameter of 100–150 mm 250–300 mm from the floor and at a short distance from the boiler firebox, install a plastic pipe in it;

- From the outside, put a special mesh on the ventilation outlet to protect it from debris, and from the inside, install a check valve that prevents air from escaping from the room;

- in the upper part of the room (preferably immediately above the boiler equipment), a hole for air outlet is made in the same way. It does not require a mesh and a check valve, but it is possible to install a visor to protect against precipitation.

If it is necessary to create artificial ventilation, which will not depend on either the weather or the air temperature, fans are installed on the same pipes for powerful boilers. Their power is selected according to the volume of the room and should provide three times the air exchange.

Chimney installation rules

Another important element of any boiler house is the chimney. Without an effective smoke removal system, combustion products will remain in the room, increasing the risk of carbon monoxide poisoning and worsening the well-being of people in the room. And for a boiler room located in a house, an inefficient chimney creates a danger for the entire building. Therefore, when arranging a system for removing smoke and gases, use the following recommendations:

- the pipes must have a diameter no less than the size recommended in the boiler passport;

- the maximum number of turns in the system is three;

- top mark chimney should not be more than 5 m above the roof level;

- the pipe must have only a cylindrical shape - that is, round or oval in cross-section;

- chimney material is metal only. Brick pipes are not suitable for gas boilers.

The top of chimneys should not be covered with umbrellas or any other protection. And there should be two holes in the wall of the boiler room. The first is intended for the chimney, the second is for its maintenance.

Conclusions

Despite large number requirements for boiler rooms, all of them are justified. Compliance with instructions and recommendations increases the safety of gas equipment operation, reducing risks to the health and life of others. And saving on creating conditions suitable for a gas boiler is not very profitable - given that the consequences may not be comparable in comparison with the savings.

The number of requirements largely depends on the power of the equipment. So, the owner of a small one-story house you will have to comply with much fewer requirements compared to residents of large buildings, especially those with two or three floors. And in order for the installation site of a large boiler to exactly comply with the standards, you will have to spend both money and time. Although the last resource can be saved by entrusting the design of the boiler room to experienced specialists.

Requirements for a gas boiler room in a private building updated: June 14, 2017 by: kranch0

Building codes and regulations provide for a number of strict requirements that apply to gas boiler rooms.

Firstly, heat generating units must be located in separate non-residential premises. It is allowed to place the boiler in the kitchen - regardless of whether it has a gas stove or gas boiler, - but only if the boiler power does not exceed 60 kW. With a heating boiler power of up to 150 kW, for a gas boiler room you need to select a separate room on any floor of the building - including the ground floor or basement. If the boiler power for heating and hot water supply is 150-500 kW, then in this case the boiler room should be located in a separate room on the first, ground or basement floor or in an extension to a residential building.

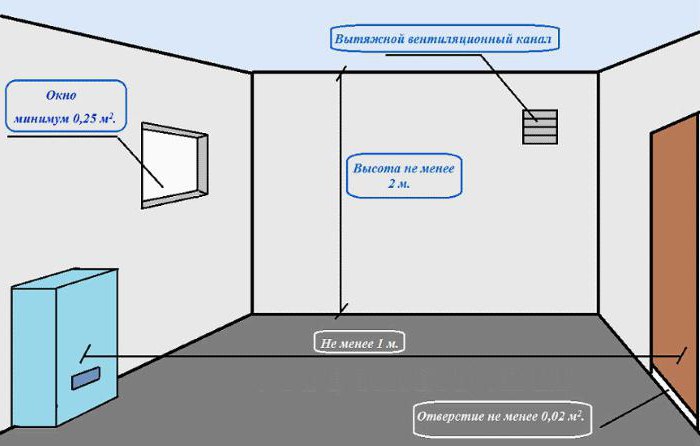

If the gas heating boiler is located in the kitchen, then it must meet the following parameters: ceiling height of at least 2.5 meters, room volume of at least 15 cubic meters. meters plus 0.2 cubic meters. m. for every 1 kW of heating unit power. The kitchen must be well ventilated - it must have exhaust ventilation in the amount of three air exchanges and an air flow in excess of the exhaust volume (to maintain gas combustion). There should be a window on the kitchen window, and at the bottom of the door there should be a grille or gap for air flow with an area of at least 0.025 square meters. m.

If a heating unit with a total power of up to 150 kW is located in a separate room on any floor of the building, then the requirements are as follows:

- ceiling height in the room is at least 2.5 meters;

- the volume of the room is not less than 15 cubic meters and the free area is suitable for convenient maintenance of the units;

- The boiler room must be protected from neighboring premises walls with a fire resistance limit of 0.75 hours and a zero value for the limit of fire spread throughout the structure;

- the room must have natural light with glazing of at least 0.03 sq.m. per 1 cu. m. premises;

- ventilation of the room: three times exhaust and inflow, exceeding the amount of exhaust by the volume of air required for gas combustion.

If heating equipment with a total thermal power of up to 500 kW is located in a room attached to a residential building, then this extension must be characterized by the following parameters.

The attached boiler room should be located near a blank part of the wall, and the horizontal distance from window or door openings for residential buildings should be 4 meters, and for industrial buildings - at least 2 meters; the minimum vertical distance from the ceiling to the window should be 8 meters.

The wall of the attached premises should not have any connection with the walls of the residential building.

The enclosing walls and structures of the attached premises must have a fire resistance limit of 0.75 hours with a fire spread limit of zero.

Minimum room height - 2.5 m.

The volume and area of the extension must ensure convenient maintenance of the equipment (but not less than 15 cubic meters).

The room must have natural lighting with a glazing area of 0.03 sq.m. per 1 cu. m. premises.

The room must be provided with a ventilation system with triple exhaust, and the inflow must ensure that the exhaust volume exceeds the amount of air that is spent on gas combustion.

If a gas boiler room is installed on the first, ground or basement floor of a building, then it must have direct access to the outside. In addition, the boiler room may have a second exit to utility room, equipped fire door Type 3.

If liquefied gas is used as fuel, then placing gas appliances in basements and ground floors buildings are prohibited.

You can order an autonomous boiler room by calling the company "ELSO Energogazmontazh". Design, installation, coordination and service.

When planning the construction of a house, you need to accurately and in advance select a place for arranging the boiler room. During a major reconstruction or redevelopment of a house, the question of where the boiler room will be located in a private house is a priority. Correct arrangement heating system, a reliable, practical and economical boiler will make the microclimate in the house comfortable and cozy for many years.

The question of where to place the boiler room in a built house can be somewhat problematic. The fact is that the old layout of the house does not always allow the installation of a boiler room in compliance with all current standards and safety requirements. But these rules should not be violated in order to avoid major troubles in the future.

A boiler room means a specially equipped room in the house, or a separate room for installing a heating system. Also, this is the whole complex heating devices and systems designed to provide the entire house with heating and hot water. The article discusses in detail all necessary conditions and stages of installation of a boiler room in a private house.

Heating equipment can be installed both inside the house and in an attached room. This is an important stage in the preparation of reconstruction or construction, which is decided in the first stages. The issue of placement is decided in each individual case, based on the capabilities of the owner of private property. The best solution is a boiler room mounted in a separate building.

A heating boiler will be installed in the boiler room, which directly serves as a heat generator. The type of boiler depends on the type of fuel used.

It is the type of boiler used that determines all the regulatory parameters required for the room, as well as correct installation ventilation system and chimney. It should be noted that the installation of electric boilers does not require a separate room; they can be installed in any room.

Types

Once again, it should be said that placing a boiler room in a constructed building is much more difficult than in the case where the room was determined in advance.

Types of boiler rooms are determined based on their location in relation to the house:

- Freestanding. Equipment installed in such a room is connected to the house using utilities. This arrangement is the most correct, since it is possible to install any type of boiler here. At the same time, its operation will not create inconvenience for residents.

- Attached. Such boiler rooms are installed in an extension to the house. The advantage is the possibility of installing a boiler room close to any building.

- Built-in. In this case, all boiler room equipment is installed directly inside the house. At the stage of designing a house, the room is located in such a way as to simplify the laying of communications to all rooms. Here you should take into account the fact that the boiler room will require additional, increased noise insulation. For example, boilers with forced-air burners make quite a lot of noise and, if there is insufficient sound insulation, will interfere with the environmental friendliness of the house.

Installation of heating equipment in the house must be carried out in accordance with SNiP. This should be done by specialists in this field.

Norms and requirements

Regardless of the type of room, when installing heating, water heating equipment and utilities, you should adhere to standard requirements and standards. The requirements for the boiler room differ somewhat depending on the type of fuel used and the type of boiler. Details of the SNiP documentation can be found on the Rostekhnadzor website. Also, exact information is indicated by the manufacturer in the documentation and instructions supplied with the heating boiler.

General requirements and standards for the arrangement of boiler rooms of all types:

- It is prohibited to place more than two boilers in one room.

- Storage of flammable and explosive substances in the premises is prohibited.

- The walls must be concrete or brick; floor – concrete (can be covered with metal sheet). The floors and walls should be tiled; surfaces may be coated with non-flammable mineral plaster.

- The heating boiler should not be adjacent to the walls on either side. Free space between the walls and the boiler is necessary for safety reasons and for necessary maintenance and repair work.

- The ventilation system and chimney must be calculated correctly, in accordance with the power and parameters of the heating boiler.

- A door that opens outward must be installed at the entrance to the boiler room. The door must be made of fire-resistant material.

General requirements for the placement of heating boilers:

- The boiler can be located in any separate room on any floor of the house. Including in basements and semi-basements.

- The location of the heating boiler in the kitchen is possible regardless of the installed gas stove. The power of the unit should be no more than 60 kW. The total power of such an individual heating system should be no more than 150 kW (including the hot water supply system).

- When installing a boiler room in an extension, or in a basement or basement, the total power of the entire individual heating system is no more than 350 kW.

- The internal dimensions of the boiler room must comply with the following standards: ceiling height in the boiler room from 2.5 m; The minimum room volume is 15 m3. Plus, for every 1 kW of boiler power, 0.2 m3 should be added.

- A prerequisite for installing a heating boiler is the installation of a ventilation system. Ventilation can be calculated based on the area of the room. Calculations are made according to the formula, based on the calculation of fresh air intake of 3 m3/s per 1 m2. This is a general calculation and is done without taking into account the number of people living in the house.

- A kitchen room with an installed boiler must have a window with a window. The door must be raised above the floor, or a grille must be installed in its lower part for fresh ventilation.

Basic requirements for the premises when installing boilers with a power of up to 150 kW:

- Such heating boilers can be installed in a separate room: in an extension, in the basement, on any floor of the house. Basic standards:

- The area and height of the room must be convenient for servicing the equipment. Room volume from 15 m3.

- The boiler room must be separated from adjacent rooms by reflective walls. The fire resistance limit is 0.75 hours. The fire spread limit across the structure is zero.

- The room in which the boiler is installed must have good ventilation and a properly equipped chimney. The ventilation hole of the air duct has a cross-section of 150 x 200 mm.

- If there is no ventilation hole under the door, a gap of 2 cm is left for natural ventilation. In this case, ventilation is carried out through a window in the window.

- The doors of the boiler room and adjacent rooms must open outward.

Device and circuit

The heating system consists not only of a boiler and pipes; there are other important devices and communications that allow the system to function effectively.

Important components:

- A heating boiler is a heat generator. The coolant is heated by the combustion of fuel in the combustion chamber of the boiler. Heat from pipes and radiators enters the room.

- The water heater tank (boiler) serves to provide the residents of the house with hot water. Inside such a tank there is a tube with a heated coolant circulating through it, which in turn heats the water in the boiler.

- Distribution manifold designed for the most convenient distribution and circulation of coolant in all devices of the heating system. The distribution manifold consists of a hydraulic distributor, circulation pump, combs. The collector also maintains the temperature of the coolant.

- An expansion tank is necessary to compensate for the increase in pressure in the system when the coolant is heated.

- The safety group is able to protect the heating circuit from excess pressure and removes excess air. Includes: safety valve, pressure gauge, air vent.

- The make-up system monitors the decrease in coolant pressure in the system due to evaporation or some other leaks.

- Pipelines, shut-off valves, used to block the flow of the medium.

- The chimney is installed to remove combustion products from the boiler to the street. The efficiency and safety of the heating boiler and system directly depends on the accuracy and quality of installation and calculation of the chimney.

- Automation is electronic device, designed for complete control of the entire boiler room. Ensures clear, coordinated operation of all components of the hot water supply and heating system.

It should be noted that all of the listed equipment for the boiler room is mandatory. The exception is the boiler, this is due to the fact that not all individual autonomous boiler rooms are designed for hot water supply.

Diagram of a gas boiler room in a house

Some additional conditions and nuances:

- Gas boiler houses have special requirements due to their increased explosion hazard.

- Electrical equipment of gas boiler houses is removed outside the premises. The lamp must be sealed. Hidden electrical wiring is laid in steel pipes.

- Boiler houses operating on liquid or solid fuels are not subject to such stringent requirements as gas boiler houses. But electrical wiring indoors must be hidden. Lighting devices must be protected with a metal mesh.

- If the boiler room is installed in a separate building, then it is necessary to provide water and a sewer pipe to it (to drain emergency drains) and take care of insulating communications running from the boiler room to the house.

In conclusion, it should be noted that the design and installation of a heating system is one of the most labor-intensive, complex and expensive engineering work in the construction of an individual house. From correct installation depends on the efficiency of the system, safety, service life and comfortable living.

Designing a boiler room in a private house is a serious issue that must be approached responsibly. In order to successfully complete all the work, it is advisable to study the regulatory documentation and get advice from specialists in this field.

In addition, remember about the ease of maintenance of the furnace, as well as ease of access to locking units. Further in the article we will consider the process of arranging a boiler room in a private house, which complies with generally accepted standards.

Basic Requirements

It is ideal to start developing a boiler room diagram at the construction design stage, that is, before the start of construction. In this case, it is possible to fully familiarize yourself with the necessary regulatory documentation that concerns this issue. This approach will allow you to take into account all sorts of nuances in advance and avoid mistakes. In the Russian Federation, the most stringent requirements are imposed specifically on gas boilers in private homes (and not only). You can study the rules in the instructions for placing heat generators MDS 41-2.2000. Further in the article, all recommendations will be based on this regulatory document.

It is allowed to install a gas boiler both in the kitchen and in a room specially designed for this purpose (furnace room). If private house has several floors, the equipment should be located on the ground floor or in the basement. Another option could be separate building, not related to living space.

Placing equipment on a flat roof is permitted if the rules for the reliability and load-bearing capacity of the coating are observed.

General restrictions:

- when installing a gas boiler in the kitchen, its power can be no more than 60 kW;

- in a separate extension (room, furnace) you can place equipment for heating and hot water supply with a total capacity of no more than 350 kW. If this indicator is exceeded, it is necessary to erect a heat-generating building that will comply with the rules and regulations for the arrangement of a boiler room;

- regardless of the type of boiler room, the ceiling height should be 2.5 meters or higher.

As for water heaters, it is not the area of the room that is taken into account, but its volume. In accordance with MDS 41-2.2000, for equipment with a thermal power of less than 150 kW, the norm is 15 m 3. For each subsequent kilowatt, an additional volume of 0.2 m 3 is added.

Equipment placement should be based on ease of maintenance. If such a need exists, place the gas boiler and other appliances with a margin of at least 700 mm on all sides. A space of at least one meter is required from the front part to the nearest partition, which corresponds to generally accepted standards for the placement of boiler equipment.

When the total power of the heaters exceeds 150 kW, they are placed only in extensions adjacent to external wall. The placement of a gas boiler and other equipment that exceed this figure inside the house is prohibited. In addition, the installation is carried out taking into account the need for maintenance and installation of utility networks.

In the extension, it is important to have windows that will perform the following functions:

- Source of natural light.

- Functions as an easily ejectable structure in the event of an explosion.

Based on the accepted standards for the arrangement of a boiler room, the window size is calculated based on the volume of the room, respectively, 0.03 m2 for each cubic meter. The dimensions apply only to glass.

Requirements for boiler room ventilation

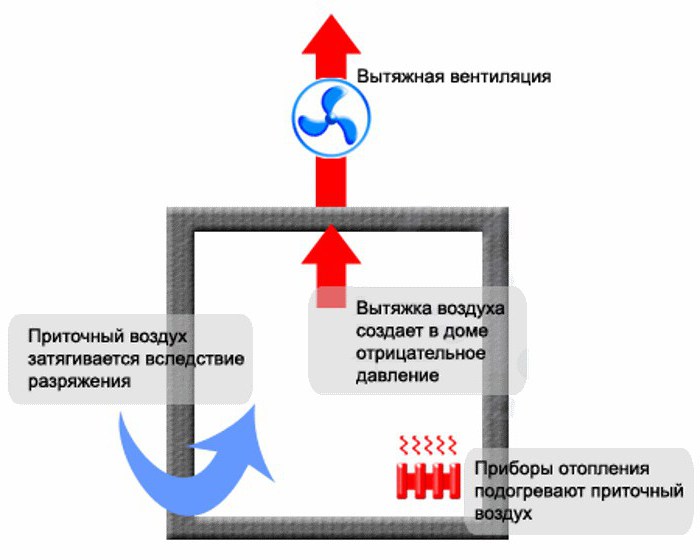

When arranging a boiler room, the most important step is proper ventilation. General rule states that the hood must provide air flow at the rate of three times exchange in one hour. In other words, the air in the room is renewed three times within an hour. This parameter is calculated simply: the area is multiplied by the height (the volume is determined), then the resulting figure is multiplied by 3. In a private house, ventilation is organized in the traditional way - through a shaft or pipe.

Supply ventilation must compensate for the exhaust air and supply oxygen in order for the combustion process to take place. The heat generator takes the mixture and then exhausts the processed air along with combustion products through the chimney. As a result, consumption supply air– this is the total consumption of the air mixture for exhaust and combustion (this is prescribed in the standards).

Security required quantity inflow is also carried out using additional holes in entrance doors. So the hood provokes the flow of additional air, which is required by the boiler room. This grille can be built into both an external door and an internal one. In the second case, already heated air will begin to flow, and the operating efficiency of the gas boiler will be noticeably higher.

Before starting work on arranging your home boiler room, consider the following tips:

- Do not rely on information that has been obtained only from the Internet, books or other information media. For every rule, advice, recommendation there must be appropriate confirmation normative document. In other cases, these are empty words and speculation.

- After familiarizing yourself with all the various requirements and rules, get advice from specialized services that will issue permission to organize and operate a boiler room. In addition to approval, it is possible to get information from them about specific nuances that you might have missed.

- You should not design and implement a boiler room yourself. Hire a design service that will save you from many potential problems in the future. If the project is simple with low power, consult a specialized engineer.

- Use your country's regulations. Do not apply the rules and requirements of other CIS countries. For the Russian Federation, study the relevant rules dictated by current legislation.

Combustion of fuel in a boiler is accompanied by the release of combustion products into the air of the boiler room. Ventilation in a boiler room in a private house is necessary to protect residents from fire, explosion, carbon monoxide poisoning and other combustion products.

It has special requirements.

Ventilation of a boiler room in a private house: requirements

The presence of ventilation prevents the occurrence of reverse draft, leading to the spread of combustion products in an individual home. The air circulation pattern in the boiler room is determined by the type of heating equipment.

Requirements for ventilation of a boiler room in a private house.

- Air is supplied to the boiler room through special channels or openings.

- The boiler room is part of the common individual house. The air outlet is through the ceiling or top part walls of the room where the boiler is located.

- For 1 kW of heating unit power, an influx of fresh air is required through openings with a cross-section of 30 cm 2 when it is supplied from the inside and at least 8 cm 2 if the draft is produced from the outside.

- There should be two horizontal channels on the hood: one for the ventilation chimney, and the other (0.25-0.35 m lower) for cleaning it.

- The distance of boiler equipment from the walls should not be less than 0.1 m.

- Exhaust and air supply are located on opposite sides of the room.

In accordance with SNiP, the ventilation of a gas boiler room in a private house must perform three air changes per hour. Its amount to support combustion is not taken into account.

In accordance with SNiP, the ventilation of a gas boiler room in a private house must perform three air changes per hour. Its amount to support combustion is not taken into account.

In accordance with accepted requirements and standards, the boiler room is created in several versions.

- Separate building.

- Extension to the house.

- Built-in room inside the house.

- In areas of the house, for example, in the kitchen.

- System in the attic.

- Block-modular system - container with equipment.

The choice of premises is determined by the performance and dimensions of the equipment.

Gas boilers up to 30 kW can be installed in the kitchen. Not suitable for liquefied gas or basement. Fuel has specific gravity more than air. Gas may accumulate if there is a leak in the lower rooms, which is unacceptable.

Requirements for the boiler room:

- floor area not less than 15 m2;

- room height from 2.2 m;

- the presence of a window with an area of 3 cm 2 per 1 m 3 of boiler room volume;

- The window must open or have a window.

Natural ventilation

Ventilation in a boiler room in a private house is mainly done using natural draft. Air can enter under doors or through ducts in walls. The supply air duct for boiler power up to 30 kW is made with a diameter of no more than 15 cm and is located no higher than the working area of the boiler. It contains a plastic pipe, which is closed on the outside with a mesh and equipped on the inside. check valve preventing air from getting out.

The exhaust vent is located above the boiler, at the top of the room, and can be equipped with a check valve. Then air will not enter the room from outside. The pipe is easy to install with your own hands. A metal rain umbrella is attached to the top of it.

A big disadvantage is the lack of control over air exchange, which also depends on the ambient temperature, wind strength and atmospheric pressure.

Forced ventilation

For powerful boiler houses, forced draft ventilation systems are installed. Fans with characteristics corresponding to the flow sections are installed in the channels. The hood power is taken with a margin of 25-30% in relation to the maximum load. The length of the air duct, cross-section and number of bends are also taken into account.

The housing in which the fan is installed must be reliably protected from corrosion and fire. For this purpose, reliable coatings, aluminum or copper alloys are used.

Forced draft is expensive in terms of equipment and energy costs. You can reduce energy consumption if you use only pressure or exhaust. But it is truly effective only when air is pumped in and out by fans.

An automation system is required in the boiler room. It not only ensures safe operation of the equipment, but also reduces gas consumption by reducing gas consumption when it is not needed.

Ventilation of a boiler room in a private house: norms and rules

The basic rules regarding boiler room ventilation are as follows.

- The location of the exhaust duct inlet is at the top.

- The presence of an additional channel for cleaning the exhaust pipe.

- Providing fresh air through ventilation duct or under doors.

- If the air supply is from the street, the size of the vent per 1 kW of power is at least 8 cm 2, and for inflow from other rooms - from 30 cm 2.

Chimney for boiler room ventilation

Ventilation in a boiler room in a private house is equipped with a separate chimney that is not connected to the exhaust of the heating system. Separate rules and regulations have been developed for it.

- Combustion products from the furnace are not allowed to enter the room. The diameter and length of the exhaust pipe are determined by the boiler power.

- To create the necessary draft, the outlet of the chimney must rise above the roof ridge by at least 2 m.

Calculation of the ventilation system

A 3-fold air exchange per hour is achieved in a boiler room with an optimal height of 6 m. Due to the fact that it is difficult to ensure this in a private house, the air exchange is increased by 25% for each meter of height reduction.

A simplified calculation of boiler room ventilation includes the following parameters:

- volume v = b * l * h, where b is the width, l is the length, h is the height of the room;

- air flow speed w = 1 m/s;

- magnification factor k = (6-h)*0.25+3.

Calculation example

The dimensions of the boiler room are 3x4x3.5 m.

We define v = 3 * 4 * 3.5 = 42 m 3; k = (6 - 3.5) * 0.25 + 3 = 3.6.

In 1 hour it ensures the passage of air in the amount of V = 3.6 * 42 = 151 m 3.

The cross-sectional area of the exhaust pipe channel will be S = V / (v * t) = 151 / (1 * 3600) = 0.042 m2.

Using this indicator, you can select the closest internal diameter of the hood from the standard range d = 200 mm. The inlet opening must have the same cross-section.

When a ventilation shaft is installed, when its flow area is less than the calculated one, forced ventilation is done to compensate for the missing performance.

Features of installation of the ventilation system

With natural ventilation, air channels are placed only vertically, not lower than 3 m. For forced ventilation, horizontal sections can be installed, but without turns.

Any homeowner is interested in the question of how to improve ventilation in the boiler room of a private house? The optimal option includes both methods of ventilation. When one of them fails, the other can be used. In both options, it is necessary that the incoming air volume be equal to the outgoing air, which is ensured by the operation of fans and dampers. But here it is important that the required system performance is ensured.

The location of the equipment must be carried out in accordance with SNiP. When using solid fuel boilers, additional fans should be installed where soot appears.

Installation of natural ventilation

Supply ventilation in the boiler room of a private house is done as follows.

- A pipe is applied to the wall and its dimensions are noted.

- A perforator is used to cut a channel with a slope of 6 0 outwards to drain the condensate.

- A pipe is inserted into the hole with a layer of insulation and a grille on the outside.

- A housing with a check valve is attached to the wall with dowels.

Exhaust ventilation is done in the same way, only the pipe is installed vertically.

Installation of forced ventilation

The presence of a fan significantly improves system performance. Supply ventilation is easy to install.

- Using a diamond core bit or hammer drill, a hole is made in the wall with a slope towards the street.

- A pipe is installed in the hole. The cracks are foaming.

- A duct fan is being installed.

- The electrical wiring to power the fan motor is laid and connected.

- Sensors, noise absorber and filter are installed.

- Grates are attached to both ends of the pipe.

Exhaust ventilation is installed in a similar way, only the air should be extracted and not forced.

Exhaust ventilation is installed in a similar way, only the air should be extracted and not forced.

Conclusion

Ventilation in a boiler room in a private house must fully comply with the requirements and standards. All of them are aimed at ensuring safety in the home. The best option is a combined system that can operate according to natural and forced ventilation.