The presence of autonomous heating in a private house requires the installation of a boiler room in it. This room needs a serious approach to its layout. There are special standards and requirements for the arrangement of a boiler room, and we will talk about them further.

Boiler room in a private house: arrangement of a room for a gas boiler

Before considering the rules for arranging a boiler room, you should familiarize yourself with the types of boilers that will be installed in it. Since the type of boiler determines certain fire safety standards and requirements in a given room.

The most popular heating device is a gas boiler. Among its advantages, one should highlight the ease and simplicity of its operation, the affordable cost of the equipment itself and the fuel that is used in it. Despite this, the installation of these boilers must be carried out in accordance with special requirements and standards, since the slightest mistake can lead to an explosion.

If a gas boiler is installed in the house, the power of which is up to thirty kilowatts, then there is no need to equip the boiler room. It is possible to install such a boiler in the kitchen or hallway, depending on their size.

Installing a gas boiler in the kitchen is possible in this case:

- if the minimum value of its area is not less than fifteen kilowatts;

- the presence of windows with an area of 30 cm square by 100 cm square;

- mandatory ventilation in the form of vents;

- minimum room height 220 cm;

- the presence of a free passage measuring 70 cm;

- the presence of an air intake hole, which ensures fuel combustion in the boiler;

- high fire resistance of the premises, including the finishing materials used for its repair.

Also, installing a wall-hung boiler is only possible if the kitchen wall is made of non-flammable or non-combustible materials. If you plan to install a floor-standing boiler, then a substrate in the form of a metal sheet or concrete floor must be installed underneath it; it must protrude beyond the outer parts of the boiler, at least 100 mm on all sides.

If the walls of the house are made of flammable materials, for example, wood, then before installing the boiler you should install a protective screen that will protect the walls from fire.

If the boiler power is from thirty to two hundred kilowatts, then a separate room is required for its installation. It is possible to install a boiler room in the basement or basement. In this case, the following rules must be followed:

- provide natural light;

- in one hour, all the air in the room must be renewed at least three times, that is, natural or forced ventilation must be organized;

- mandatory access to the street;

- minimum wall height 250 cm;

- The minimum volume of the room, as for the kitchen, is fifteen square meters.

The best option is a gas boiler room in a private house, of a separate type. Thus, it will be possible not only to improve the comfort of its operation, but also to reduce the risk of fire throughout the house. The following requirements apply to free-standing boiler rooms:

- the presence of a mandatory foundation for the building;

- lack of connection to the house;

- after the foundation of the building has been arranged, the foundation for the installation of the boiler is laid;

- the boiler is installed 150-200 mm above the floor;

- To fill the floor, a concrete solution is used, which necessarily contains sand.

For the manufacture of the roof and walls, use only non-combustible finishing materials. As for interior decoration, ceramic tiles are most often used for its implementation. In addition, to remove the coolant, it is necessary to have a sewer drain in the boiler room. In addition, before starting construction work, it is necessary to develop a project that is agreed upon with the gas workers.

Boiler room in a private house: layout diagram for a solid fuel boiler

The use of solid fuel boilers is highly popular in those regions where there is no centralized gas supply. Such boilers operate on wood, pellets, peat and other solid fuels. Among their advantages it should be noted:

- variety of fuels;

- availability and low cost of fuel;

- ease of installation and operation;

- fewer requirements and standards for the arrangement of a boiler room;

- not explosive;

- if you plan to install a long-burning boiler, then this equipment operates without human intervention for up to three days.

Despite this, solid fuel boilers have lower efficiency than gas boilers. In addition, they are quite sensitive to high air humidity and require constant loading of fuel and cleaning of the boiler.

We suggest that you familiarize yourself with the basic rules according to which a boiler room is equipped for boilers operating on solid fuels:

- the place where the boiler will be installed must be easily accessible, since fuel is constantly loaded into it and the ash pan is cleaned;

- the minimum distance between the wall and any side of the boiler is 100 mm;

- when installing the boiler near walls lined with highly flammable materials, it is recommended to cover them with a metal sheet, the thickness of which is 2.5 mm;

- In front of the base of the firebox, material in the form of a steel sheet should also be laid.

Please note that it is best if the floor in the room in which the boiler is installed is made of concrete and lined with any non-combustible material.

Please note that special requirements apply to the arrangement of the ventilation system:

- for one kilowatt of boiler equipment power, it is necessary to arrange 80 cubic millimeters of windows;

- the diameter of the boiler chimney opening should be smaller than the diameter of the chimney;

- in addition, care should be taken to ensure that there is a special hole that will allow technical work to be carried out on the chimney;

- the chimney must have the same diameter over its entire area;

- the inside of the chimney must be plastered, so that smoke will not enter the room;

- in addition, the premises require a water supply and sewer system;

- if coal or wood is used to heat the house, then the minimum area of the boiler room is eight square meters.

If only coal is used as fuel for the boiler, the boiler room must contain hidden electrical wiring and special hermetic lighting devices, since coal dust is highly explosive.

Please note that in addition to a properly installed chimney, the room must have natural or forced ventilation. Since every time fuel is added from the boiler, its combustion products enter the room. Their accumulation will lead to the release of carbon monoxide.

Boiler rooms in a private house photo: room for an electric boiler

An electric boiler is one of the safest heating boilers. In addition, its installation does not require a separate room, but any free corner of the house is sufficient.

Among the advantages of electric boilers we highlight:

- affordable cost of the device itself;

- ease of installation, which does not require the involvement of specialists;

- saving space, since boilers of this type are compact;

- safety, since there is no open flame in the boiler;

- no need to install a chimney;

- noiselessness and comfortable operation;

- environmental safety.

Despite this, electric boilers have certain disadvantages:

- possibility of receiving an electric shock;

- the need for grounding;

- high cost of electricity used for heating.

The use of such boilers is quite rare, since electricity costs are too high. Such boilers are most often used as additional heating sources.

Requirements for a boiler room in a private house

We suggest that you study in more detail the requirements for a gas boiler room in a private house:

1. What should the boiler room be like?

- if you plan to equip a boiler room in a private house, then you should definitely allocate a separate room or an extension for it; installing a gas boiler in a living room is unacceptable;

- the minimum ceiling height in the room is 220 cm;

- the size of a boiler room in a private house is calculated based on four square meters for the installation of one boiler;

- The walls of the room must be plastered; do not use highly flammable finishing materials for their finishing;

- the minimum width of the doorway is 80 cm;

- ten cubic meters of room requires thirty centimeters of square windows.

2. The presence of communication systems is mandatory.

- the electrical network must be characterized by the presence of a single-phase current of twenty Amperes and a voltage of 220 V, it is necessary to have grounding and install a special circuit breaker that protects the network;

- each boiler must have a shut-off unit;

- in addition, water must be supplied to the boiler room, with the help of which hot water is supplied to the house;

- to ensure emergency drainage of water from the system, a sewerage system should be installed;

- Monitor the gas and water pressure in the system, which must be in accordance with certain standards.

3. Ventilation system in the boiler room.

- if the house has previously organized ventilation, then it can be combined with the ventilation of the boiler room;

- to install a chimney, you need to punch two holes located directly in the wall;

- to supply air, it is enough to make a hole in the wall or door and install a ventilation grille on it;

- To calculate ventilation, the boiler power is enough, for example, 2 kW multiplied by 8 square centimeters, the result is 16 square centimeters - this is the area of the minimum ventilation hole for the boiler room.

4. Chimney and rules for its installation.

- any type of chimney installed in the boiler room must be gas-tight; fuel combustion products must not enter the room under any circumstances;

- the hole for the chimney, which is located on the boiler, should be smaller in diameter than the chimney itself;

- After installing the boiler, it must be freely accessible from all sides.

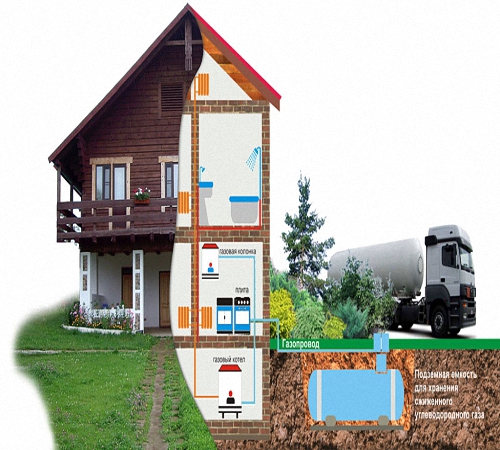

Installation of a boiler room in a private house: main components of the equipment

Boiler room designs for a private home vary in the area of the main room and technological features, however, almost any boiler room includes the following components:

- boiler for a heating system - a device that generates heat to heat a house; the boiler contains a combustion chamber, in which energy is released from the fuel, with the help of which the coolant is heated and the entire building is heated;

- water heating tank in the form of a boiler - performs the function of heating water, is used only in double-circuit heating systems, thus, the boiler not only heats the building, but also performs the function of supplying hot water;

- expansion tank - is able to compensate for too high pressure in the system that occurs when the boiler heats up too much; the liquid, during the heating process, heats up and increases in volume, while the pressure in the system increases to prevent pipe rupture, an expansion tank is used, excess water enters it, then, in the process of cooling, they return back under pressure;

- in order to distribute the coolant fluid in the system and ensure uniform heating of all rooms, it is necessary to have a distribution manifold; in addition, with the help of this device, it is possible to regulate the temperature of the coolant fluid; this device contains a circulation pump, a comb and a hydraulic separator;

- chimney - allows you to remove fuel combustion products from the room; the quality of work and efficiency of the heating system itself depends on the correct technology for installing the boiler;

- to protect the system from overheating, it is necessary to have a safety group, which includes a thermostat and an expansion tank;

- In order to transport the coolant in the system, it is necessary to have a pipeline and shut-off valves that help block the movement of the coolant.

1. Please note that there should be a maximum of two boilers in one room, no more.

2. The choice of a chimney, exhaust system and their features directly depends on the type of boiler that will be installed in the boiler room, therefore, before arranging the room itself, it is advisable to purchase a boiler.

3. For the manufacture of boiler room walls, it is best to use refractory brick or concrete.

4. Ceramic tiles, plaster or steel sheet are used to finish the floor.

5. If there is an adjacent door between the house and the boiler room, it should be made fireproof.

6. The presence of free space around the boiler is mandatory, as it provides free access to the equipment in case of repair.

The area of the boiler room in a private house depends on the power of the boiler.