- How to correctly calculate floor beams?

- Calculation of the load on the installed floor

- What cross section should the beams have?

- How to calculate floor beams using an example?

Accurate and correct calculation of floor beams must ensure their main quality - reliability, therefore preparation of wooden products is carried out only after calculation of all dimensions. Among the main calculation parameters, the length and cross-sectional size of the product stand out.

The future floor must have a certain width, which determines the length of the beams. The cross-section of the product is calculated based on the planned load on the installed floor, the installation pitch, and the span length. All calculations must be made in accordance with a special methodology.

How to correctly calculate floor beams?

Beams are structural elements for performing load-bearing functions. The calculation of beams and their installation is subject to compliance with the following rules:

- When the span is measured, only after that the required number of wooden products, their length with all other dimensions are determined.

- An important point is to take into account the depth provided for introducing structural elements into the walls and securing them.

Brick walls require a depth in the walls of at least 150 mm, provided for wooden products that are made from timber. If they are made of boards, then the depth will be at least 100 mm. For cutting them in wooden houses, a minimum depth of about 70 mm is provided.

If during installation of the structure corners or brackets will be used, then the length of the products is taken equal to the span. The weight of the entire floor in this case must be supported by metal structures. In this way, it is usually possible to cover a span whose length ranges from 2.5 to 4.0 meters.

A wooden product made from timber must have a maximum length of 6 m. For house projects that require the use of longer beams, glued laminated timber or intermediate supports, which are partition walls, are used.

Return to contents

Calculation of the load on the installed floor

The load transmitted by the structure is summed up, taking into account total weight simultaneously with the weight of the insulation. At the same time, the sum of the weights of all objects is obtained. Performing a correct calculation is only possible if the services of specialists from a design organization have been used.

If you use another calculation method, it will only be available if you perform it yourself according to the following scheme:

- If the attic elements have a sheathing board in the absence of large loads, then their effect will be 50 kg per square meter if insulated with mineral wool.

- The calculation of the load on the structure will be: 1.3*70 = 90 kg/sq.m; 1.3 – safety factor value.

- The total load should be calculated as follows: 90 + 50 = 130 kg/sq.m.

If the structure contains inter-beam insulation, which is heavier than mineral wool, a lining of boards of sufficient thickness is used. The load level will be 150 kg/sq.m, with: 150 * 1.3 + 50 = 245 kg/sq.m – the total load.

Additional load factors in the presence of an attic are the mass of the existing floor covering, furniture, and other items, so the increase in load will be up to 350 kg/sq.m. The load value is taken to be 400 kg/sq.m when the beam is part.

Return to contents

What cross section should the beams have?

After determining the length of the products, taking into account design load the pitch is calculated, as well as the cross section. If logs are used, their diameter is calculated. These values are related to each other, so the ratio of the height of the product to its width should be in the optimal ratio of 1.4:1. You can select the dimensions depending on the thickness of the insulation, which can vary in the range of 100-300 mm. When using logs, they are taken with a diameter of 110 to 300 mm.

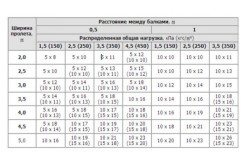

The choice of installation pitch of the structure should be in the range from 300 to 1200 mm. Be sure to take into account all the dimensions of the inter-beam insulation used, as well as the material for filing. The distance between the posts of the frame structure must correspond to the pitch of the beams. The distance between the beams can be found in the table.

For attics, the permissible bending value is equal to 1/200, and interfloor ceilings require a parameter value equal to 1/350. When calculating the cross-sectional size, reference literature is usually used.

The attic floor must be strong enough to withstand the required load. The strength of the floor is influenced by several parameters that can be changed - the span, the cross-section of the beams, the pitch of their installation, the connections between the beams...

Let's take a closer look at how to choose attic floor beams for a private house, the method of their calculation, and design options.

Factors determining the load on the floor

The load on the attic floor is created by:- the weight of the ceiling itself;

- temporary operational load - people, loads that may be on the ceiling.

If screed and partitions are additionally used, then their specific gravity must be increased. Typically, when using dry screed and lightweight hollow interior partitions, the specific load from wooden floor and these structures are taken equal to at least 100 kg/m2.

Determining the load on the attic floor

The temporary operating load may vary depending on the purpose and use of the attic space.- If the premises are not used at all, then the specific operating load according to SNiP is taken to be at least 100 kg/m2. (75 kg x 1.3 - safety factor).

Then the total specific load on the attic floor will be 100 + 50 = 150 kg/m2. - For interfloor slabs, the temporary operational load, according to the standards, must be at least 200 kg/m2 (150 kg x 1.3).

If an unheated attic is supposed to serve as a warehouse for unnecessary things, then it is equivalent to an interfloor ceiling. - If the attic floor is residential, and a floor screed (floating floor with sound insulation) and light intersection partitions, furniture, equipment, etc. are used, then accordingly the interfloor ceiling

will have a total specific load of 300 kg/sq.m. (200 + 100 kg/sq.m.).

Determination of the section and installation pitch of beams

The initial data for the calculation were previously determined:- total specific load on the attic floor;

- the size of the span between load-bearing walls;

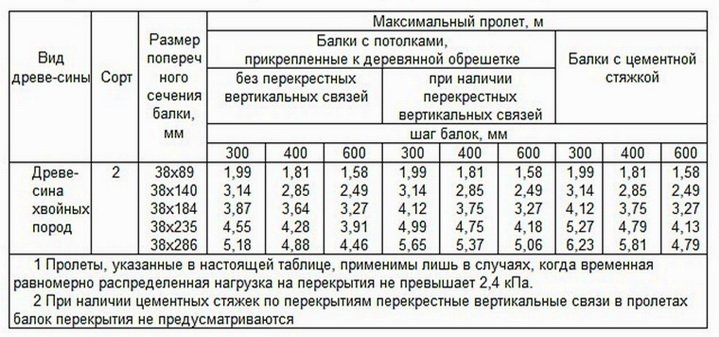

You can use the tables for selecting beams for attic floors, which are given in SP 31-105-2002 “Design and construction of energy-efficient single-family residential buildings with a wooden frame”,

For an unused attic, the following section of floor beams and their installation pitch are proposed, depending on the size of the floor. But here the temporary operating load is assumed to be 35 kg/m2. - This is a very rare visit to the attic by only one person. This ensures that the beam deflects no more than 1/360 of the span length.

The following table is for interfloor slabs with a specific load of 240 kg/m2. The maximum deflection of the beam is also provided for no more than 1/360 kg/sq. m.

There are also different calculation methods for designing beams, and at the amateur level various programs and calculators are used. You can see:

Additionally, read:

What connections should be used between beams made of boards?

If wooden boards are used as beams (no wider than 80 mm with a height of up to 250 mm), then measures must be taken to prevent the beams from twisting. It will be enough if the boards on top and bottom are sheathed (connected to each other) with continuous flooring made of sheet rigid materials such as chipboard, CBPB, OSB, plywood... with a thickness of at least 12 mm, for a beam installation spacing of no more than 600 mm.Sheathing joints should be located in the center of the beams. The fastening of the skins is carried out with self-tapping screws in increments of 200 mm to a depth of 40 mm.

The result will be a frame that not only prevents twisting, but also increases resistance to deflection and vibration.

On one side, the frame can also be formed by counter-lattice slats, which are installed perpendicular to the beams with a pitch of no more than 600 mm and a cross-section of at least 20X90 mm. The sheathing can be sheathed with a less rigid material - gypsum fiber board, gypsum plasterboard.

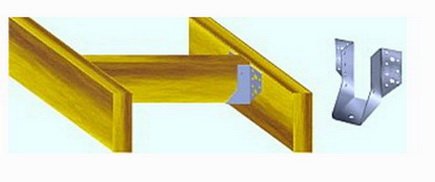

If the upper continuous cladding of the beam-boards is not provided, and there is no counter-lattice, then the frame is strengthened with vertical struts. They are inserted between the beams and attached to them with metal corner elements, their cross-section is from 40X100 mm. The installation step of such connections is no more than 2.1 meters, but usually they are placed at the joints of the ceiling cladding, while the lower counter-lattice is not made.

When choosing boards for flooring, you should take into account that wide, even boards are more expensive than narrow ones (calculated per 1 cubic meter).

The height of the board (beam height) must be selected based on decision taken about the placement of the entire layer of insulation and the construction of counter-battens.

The pitch of the beams can be reduced based on the feasibility of fastening the sheathing, a multiple of the size of the sheets.

You can also find out

It is impossible to build a house without connecting elements - floors. They are the supporting foundation of each floor of the building. Even if the building is one-story, the ceilings serve as the ceiling and floor. The entire weight load falls on the floors. Things that are in the premises, people - all this load must be successfully carried. It should also be taken into account that with each additional floor the weight load on the underlying areas increases. This is why the correct calculation of floor beams is so important.

What are floor beams

Traditionally, wooden and reinforced concrete floors are used in houses. They represent a dividing plane between the floors of the building. Each of them is installed along the main load-bearing elements - floor beams. Their strength is very important. In addition to the load that the floor itself can withstand, the beams also take on the weight of the structure separating the floors itself.Rules for laying floor beams

If a brick building is being erected, then special holes are left in the walls for the construction of interfloor ceilings, which are prudently left during the laying of the walls. If the house is being built from wood, then the holes into which the beams will subsequently be laid are simply cut down in the right places. The beams must be laid in such a way that the supporting length of the ends extends into the openings by at least 15 cm. The horizontalness of the laying is checked by a level or spirit level. To maintain the exact distance between the beams being installed, you can use a piece of lath of the required length. It will serve as an indicator of the distance through which the next beam should be installed. These supporting elements should be fastened every two beams. They are made using anchors. To align the beams horizontally in the openings in which they are laid, you can place wooden dies under their ends. We should not forget about insulation when carrying out this work. All the free space that remains in the openings after installing a beam in it. should be filled with insulation. Typically glass wool is used for these purposes. It is also important to do waterproofing. Therefore, pieces of roofing felt in two layers or dense polyethylene are laid in each opening. Beams can be positioned in both parallel and cross directions. But the latter is quite difficult to install and is rarely used in practice.

Calculation of floor beams

The basis for calculating the cross-section of the beam that will serve as a support beam is the following rule: the cross-section of the support must be at least 1/25 of its length. For example, if the length of the beam is 6 meters, then its thickness should be at least 25 cm. The shape of the room over which the ceiling is erected is often rectangular. It is more expedient to lay the beams in such a way that their length is as short as possible. That is, the support for their ends should be the openings in the longest walls of this room. For example, if its dimensions are 3/6 meters, then the beams should be installed three meters long. But this is a conditional figure, since it only indicates the width of the span. The beam itself should be 50-60 cm larger for the reason that it should rest on the walls at both ends by at least 25 cm. Next, in order to correctly calculate the floor beams, the weight load should be taken into account. For residential buildings its average value is 400 kg/m2

For an attic floor this value can be half as much. Next, the distance between the beams is included in the calculation. It can be 1 meter, 75 cm or something else. Optimal width span for wooden beams - 2.5-4 meters. The best beam shape is rectangular, with a beam height to width ratio of 1.4:1. Next, the maximum bending moment is calculated using a special formula. If the distance between the beams is 1 meter, then it will be 80000 kg/cm. There are special tables that show average indicators for certain types of wood, take into account the percentage of wood moisture content, its service life coefficient and many other indicators. All this can be found on specialized websites or in the literature on house construction. In the event that the joists will first rest on the floor beams, and then the boards, then the cross-section of the joists should also be calculated.

Read also:

Beam floors

When choosing the type of flooring for a future home, the general concept of the structure is of great importance. It is unlikely that anyone would think of wooden cottage use a metal I-beam or reinforced concrete beam as a floor. There are certain rules and regulations that impose their own limitations on the design and make their own adjustments.

02/24/2013 at 13:02

Types of floors. Requirements for floors.