Steam heating is a type of heating that uses superheated water vapor as a coolant. It was this type of heating that was used at the beginning of the 19th century to heat residential premises. Steam was later replaced by water, but the name "steam heating" is still often used (incorrectly) to refer to centralized heating systems for residential buildings. We have already written about this in an article about this very thing.

The reason for refusing to use steam as a coolant was the high degree of heating of the surface of heating devices up to 100 degrees Celsius or more. Any contact with the surface of a heating radiator could cause a burn, and a broken pipe could lead to serious injury and property damage.

Currently, the use of steam heating in residential and public buildings is prohibited. It can only be used for heating industrial premises, passages, entrances and greenhouses, if the heating system does not pose a danger to people.

There is no ban on the use of steam heating in private homes. Here everyone is free to do as they see fit. But before you make your choice, you need to analyze all the pros and cons of steam heating.

Let's start with the pros:

- The steam heating system is not in danger of defrosting. It can be turned on and off at any time of the year, without fear that the coolant will freeze. It is this factor that is decisive when choosing steam heating for a country house.

- Steam heating is efficient: heating devices transfer thermal energy to the surrounding space by convection and radiation. For comparison, with water heating, the convective component is predominant in heat transfer, and the emissivity of radiators is low.

- When installing steam heating, you can use smaller diameter pipes and smaller radiators

- There is virtually no heat loss in heat exchangers

- Low cost heating system

Disadvantages of steam heating

- High surface temperature of heating devices

- High degree of corrosion of the heating system

- High emergency hazard in case of heating breakthrough

- Noise when steam moves in the heating system

How does steam heating work?

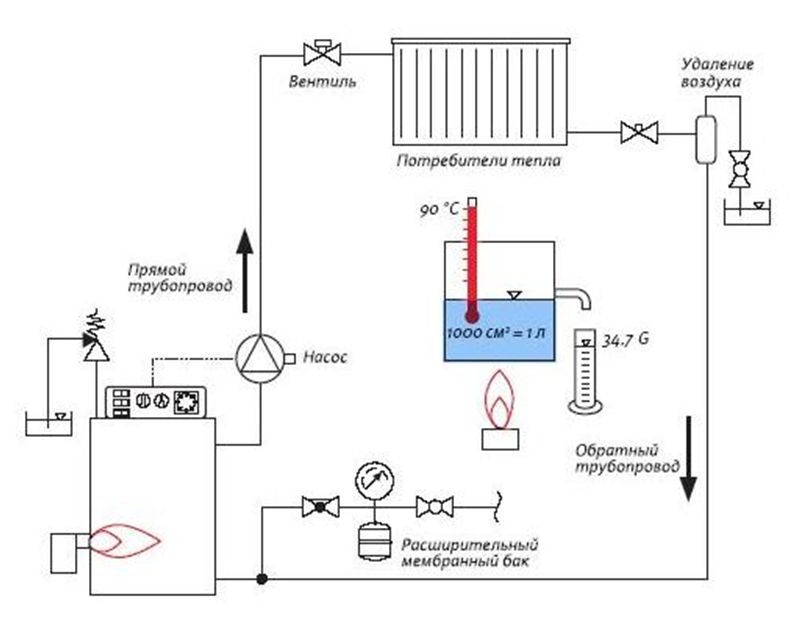

Steam heating systems for private homes use a low-pressure steam boiler that generates superheated steam and supplies it to the heating system. Steam moves through the pipes, cools and condenses on their inner surface, releasing a large amount of thermal energy, which is the basis for the high efficiency of steam heating.

For comparison: condensation of one kilogram of steam releases 2300 kJ of thermal energy. At the same time, when a kilogram of steam cools by 50 degrees, only 100 kJ of thermal energy is released. The resulting condensate (water) is returned by gravity to the boiler or supplied to it using a pump.

The steam pressure in steam heating systems of private houses can be lower than atmospheric (in this case we are talking about vacuum steam systems) or higher than atmospheric with a pressure of no more than 6 atm.

To regulate the heat supply in steam heating systems of a private house, a change in steam flow is used. If necessary, the steam supply is stopped, creating conditions so that the house can cool down.

Cast iron and steel radiators, as well as finned pipes, are used as heating devices in a steam system.

Types of steam heating systems

The steam heating system of a private house can be closed or closed. In it, the condensate returns by gravity to the boiler. In this case, the condensate return pipes are made of a larger diameter.

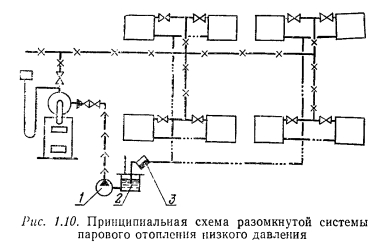

For private houses, open or open steam heating systems are also used, in which condensate is collected in a separate tank, and when it is filled, it is pumped into the boiler using a pump.

Video - Make a heating boiler with your own hands

Steam boiler

![]()

For private homes, low-pressure steam boilers (up to 6 atm) are produced with a temperature limit of superheated steam of no more than 130 C. Steam boilers can operate on any type of fuel. Considering that steam is a source of danger to human health, it is recommended to use only boilers with appropriate quality and safety certificates in heating systems.

The boiler must be equipped with a pressure gauge to measure the steam pressure level. The boiler is installed below the level of heating devices and pipelines. This creates optimal conditions for the upward movement of steam, as well as for the gravity return of condensate from the heating system to the boiler.

When steam is supplied, there are usually no problems with the formation of air pockets. The air is displaced by a stream of steam and discharged through special valves.

Selection of pipes for steam heating

For steam heating, steel or copper pipes are used, the connection of which is made by welding. Plastic pipes are not used in steam heating. The connection of heating devices and pipes can be threaded or welded. It is important that it is sealed and resistant to steam.

Installation sequence

You already understand what is needed for a steam heating system. But how to make steam heating correctly? We need to start by drawing up heating system design diagrams and put it on paper. Take into account all the details: the length of the pipes, the presence of tees and adapters, turns, risers, radiators. Place the boiler in a specially designated place (not in the basement) with ventilation. An expansion tank should be installed 3-4 meters higher from the boiler. Lay a pipe from it, attach a radiator to it and install the entire system according to the diagram.

For steam heating, the following design schemes for laying pipelines are used:

- With overhead steam distribution line

- With bottom location of steam distribution line

- With intermediate gas distribution line

- With laying of dry condensate pipeline

- With laying of wet condensate line

Diagram “a” shows a steam heating system with an upper distribution steam line, where saturated steam from the boiler enters the steam line through a separator, passes through heating devices, condenses, releasing heat to the environment.

The resulting water flows through the condensate pipeline into the boiler. In this case we are talking about a wet condensate pipeline. The boiler is fed with water through the pipeline.

The figure also shows a diagram of the location of a steam valve designed to regulate steam flow, as well as a tee designed to distribute steam evenly across heating appliances.

Top steam distribution is the best option for steam heating of a private home. Sometimes, to reduce the number of pipes when installing a heating system, a lower steam pipeline is used, the disadvantage of which is that condensate drains towards the movement of steam, which can cause water hammer.

It is considered more rational to lay the steam pipeline with a slope towards the movement of steam, and the condensate pipeline with a slope towards the movement of the boiler. For convenience, bypass loops are installed in such a system.

If the heating system is branched, a collection tank equipped with a float is used to collect condensate. When it is filled, the pump turns on and the condensate is pumped into the boiler.

Steam heating elements

Before installing steam heating, you need to make a list of necessary purchases to install the system.

- The entire heating operation in the house depends on the choice of a high-quality steam boiler. It must be selected depending on the area of the premises to be heated. Up to 200 m2, a boiler with a power of 25-30 kW is sufficient, for 300-600 m2 - 30-60 kW, for an area larger than 600 m2 you need a powerful boiler from 60 kW. The boiler can operate on solid fuel or gas.

- You can choose the pipes you like. Steel pipes are reliable and durable, but their installation requires welding, and they are also not resistant to corrosion. Stainless and galvanized are connected without welding, but very expensive. The best option, but also not cheap, would be copper pipes. They tolerate high pressure and temperature well and are connected by soldering at high temperatures.

- Radiators are reinforced, for system pressure 16 bar and standard - 6 bar.

The main thing in a steam heating system is the boiler. He heats the water to a boil. As a result, steam is released, which immediately accumulates. Since high pressure is formed, steam enters through the pipes and at the same time expels the accumulated air. Then the steam is compressed and enters the boiler again in the form of water. Based on the method of returning condensate to the boiler, open and closed heating systems are distinguished. In open systems there is a separate tank for condensate, which then pumps water into the boiler. And closed systems have a wide pipe through which the condensate itself flows directly into the water heater.

It happens - in addition to heat, hot water is obtained from it for domestic needs.

It is beneficial to install steam heating in country houses, multi-storey cottages or houses with several outbuildings that need to be heated. If you find it difficult to figure out how to install steam heating in your home, then it is better to turn to professionals who will help you.