In individual, and not only in individual construction, when the scope of work reaches large volumes, some work and technological elements provided for in the project can be postponed for more late date, concentrating on the main direction. One of these options is the installation of a roofing system. And here the point is not only to save on materials by postponing the attic equipment for later, simply by erecting walls, interfloor ceilings and laying basic communications without a device reliable roof no way. And if for a speedy check-in it is necessary to carry out a mass finishing works indoors, then you can wait a bit with installing insulation in the attic.

What does a cold roof mean?

Modern roofing materials, despite such a variety of shapes, materials, technologies and prices, are largely similar to each other in one thing - they can be used both for installing a cold roof of a building, and when constructing a roof with a layer of insulation. Essentially these are materials universal application, but when working with them you need to know and take into account the specifics of their application.For roofs equipped for attic spaces, a layer of insulation is used to prevent heat loss in winter time and storage indoors comfortable temperature in summer. For such options, they are used as traditional insulation technologies using as insulation mineral wool, polystyrene foam, sprayed types of insulating foam, as well as new types of new insulation materials on a natural basis that are just coming into fashion. The roof of such a building makes it possible to obtain additional space in the building, which can be used as a workshop, library or billiard room.

A cold roof, unlike a structure with insulation, has a simpler structure. This is a standard roofing structure, the main purpose of which is to protect the building from precipitation. At the same time, the installation of a cold roof can also be done as an intermediate solution, in which it is subsequently planned to install a roofing pie made of insulation and all the accompanying layers of hydro- and vapor barrier.

Cold roofing can be made from almost the entire range of roofing materials; for its installation the following can be used:

- Slate;

- Profiled metal sheet;

- Metal tiles;

- Roofing iron;

- Roll roofing materials;

- Ondulin;

- Bitumen-based materials;

- Roof tiles.

Cold roofing made of rolled metal

In order to quickly erect the roof of a building with the least loss, the most rational option today is to use a sheet metal product as a covering material. Metal profiled sheets or metal tiles have several advantages compared to other types of roofing materials:- Coverings made of metal tiles or profiled sheets are highly reliable and durable; the service life of such coverings is at least 50 years, provided that all rules of roofing technology are observed;

- Metal tiles and corrugated sheets are truly universal materials - they can be easily used to cover both large areas and small-sized roofs.

- The material, unlike tiles or slate, has less weight, which means that lighter structures can be used for the rafter structure;

- The strength of the material, as practice shows, is beyond any doubt; it can withstand heavy loads perfectly and cope with its functions on various roof slopes from 14 to 65 degrees;

- The convenience of installing a roof from these types of materials is indisputable, except large sizes and ease of installation of the roof, the metal profile itself and metal tiles include many additional accessories that allow you to install all the roof elements without any difficulties.

Metal as a roof covering, except all of the above positive qualities It also has negative ones, which very seriously affect both the condition of the roof itself and the condition of the metal. Firstly, the daily temperature difference in the spring-summer period makes it possible for inner surface a drop of condensation. Secondly, metal roofing requires the installation of special additional elements for laying communications through the coating. Thirdly, the roofing material itself is still very noisy; during rain or hail, those under the roof will clearly hear literally every drop of rain or grain of hail falling.

Based on this, installing a cold roof using metal materials requires the use of special additional materials and installation technologies recommended by the manufacturer.

The specificity of equipping a building with this type of roof is the use of materials that make it possible to completely or partially rid the interior space of the formation of condensation, and if it appears, remove it from the attic space as quickly as possible.

The basis of such a roof, like any other roof of a similar type, is a rafter structure, the standard set of which is rigid rafters located in strict accordance with the design, interconnected into a rigid structure. The dimensions of the rafters themselves, the shape and methods of joining each other in this case do not play a special role; it is important that the slope of the rafter legs provides the most optimal slope angle from 14-65 degrees.

A layer of waterproofing material is laid on top of the rafters. The essence of this layer is the ability to protect against moisture from getting into the attic space from leaks in the roof. Modern nonwoven materials make it possible to solve the problem of moisture from condensation in a comprehensive manner; today, the material used today is mainly a vapor-permeable membrane that is capable of passing steam in one direction and not allowing moisture and steam to pass back. This layer of waterproofing is laid on the rafters and secured with construction staples.

Counter battens are attached to the rafters on top of the membrane. The strips not only secure the membrane itself, but also thus form additional volume between the membrane and the coating. Further, as in usual roofing structure sheathing strips are installed and metal sheets of covering are installed on top.

Such a schematic representation allows the main elements of a cold roof, but to complete the picture it is necessary to dwell in more detail on some of the nuances of the design.

Vapor-permeable membrane waterproofing installed on top of the rafters is laid in sheets horizontally from bottom to top, so that the layer located above overlaps the bottom layer by at least 10-12 cm. This arrangement will allow moisture to quickly drain down when it gets under the metal coating. However, when laying the waterproofing layer, the material is laid without tension, with a deflection between adjacent rafters of 1.5-2 cm. This deflection ensures more efficient removal of moisture and at the same time increases the internal space under the metal tile.

Below on the rafter beams, not only drip lines are installed - solid metal strips along which water flows from the tiles, but also a special perforated strip or mesh with small cells to ensure unhindered passage of air under the roof. Perforation reliably closes the space from birds, bats, animals and large insects entering the attic and at the same time provides air flow under the metal surface.

Constant air circulation is ensured by the presence of additional holes in the upper part of the roof under the ridge strip, allowing heated air to pass through. This roof design allows air to circulate with the greatest efficiency; the air, passing under the metal covering, gradually heats up, exits through the holes under the ridge strip.

Conditions for laying communications under a cold roof

Just like for a conventional roofing structure of a house, the space under a roof made of metal profiles or metal tiles can be equipped with a chimney, cable or antenna lines, and can be installed in the roofing. ventilation ducts and viewing windows or glass inserts.

For a cold roof, the placement of these communications has some features. For chimneys passing through the attic space, especially those that use metal structures as pipes, it is necessary to mandatory carry out insulation, since it is these elements that will cause condensation on the profile. For cable lines passing through the metal covering of a cold roof, it is necessary to use special antenna outputs that fit tightly to the surface of the metal tile.

A cold roof, in addition, requires that in addition to the main ventilation system, auxiliary ventilation ducts must be installed to remove air outside. Most often, special ventilation outlets with deflectors are used as such channels, providing air draft.

A little about saving

When considering the option of constructing a building with a cold roof, as a permanent or intermediate roofing option, it is necessary to understand some of the nuances associated with the economic aspects of this type of structure. When comparing the design of a cold roof for a two-story single-apartment residential building with the same roof, only with insulation, it is necessary to add another 10-12% of the amount of annual costs to the heating costs of the task. At the same time, simple insulation of the attic surface gives reverse effect in the form of energy savings of 3-5% of annual needs.When evaluating the construction of a cold roof, it will undoubtedly cost less, while the cost of the project can be 35-50% less than the cost of an insulated roof. But in order to carry out insulation work in the future, a cold roof as an intermediate option is the most optimal, because the space can also be used as extra space storage of material. True, insulating such a ready-made roofing system will be a more complex process than building a roofing pie right away.

When planning your home design, you always want it to be warm and cozy.

To do this, you should follow the instructions when carrying out construction work.

It is also necessary to pay enough attention, in particular, to the competent provision of all types of insulation.

How to choose a vapor barrier for a roof and not make a mistake? First, let's get acquainted with the types of vapor barrier materials.

In residential premises there is always water vapor that circulates inside it. And according to the laws of physics, it rises with the warm air. Over time, it will penetrate into the under-roof space, where it will begin to absorb insulation.

With the onset of cold weather, all the moisture that has undergone condensation forms an ice crust. And when spring comes, all the ice melts, and the resulting moisture washes away the internal filling of the roof structure. This will lead to its destruction and loss of basic properties: When the insulation is slightly moistened, heat loss increases significantly.

To avoid these consequences, it is necessary which should be present in any roofing pie. Some people believe that finishing the attic with cladding, which prevents moisture from entering, eliminates negative consequences. But it is recommended to always use a special coating that is placed between the ceiling and the insulation.

Which vapor barrier to choose for the roof?

There are the following types of vapor barriers for roofs:

- painting;

- pasting.

Painting room

Used more often for high-rise buildings, soft roofs from roofing felt, iron roofing sheets, where insulation is not used. This vapor barrier is well suited for flat roofs. The main difficulty in using mixtures of this kind is preparing the surface before application. For this type of insulation, the following compositions are used:  How:

How:

- hot bitumen;

- bitumen-kukersol mastic;

- varnish based on chlorinated rubber or polyvinyl chloride.

Pasting (membrane)

This type is more popular, especially in individual construction. Materials for this type of insulation are produced in rolls and this provides some advantages:

- simplification of installation;

- ensuring a tight connection when overlapping;

- reduction in the number of seams.

PLEASE NOTE!

The adhesive insulation is laid in one layer, if the room humidity is below 75%, otherwise add one more extra.

Types of adhesive vapor barrier materials

- Waterproofing. Prevents steam from penetrating into the insulation. Have special perforation, which allows vapor to penetrate outside. It is mounted with some clearance from the roof covering, which promotes air circulation between the outer and under-roof space. Has unidirectional vapor permeability, keeps the insulation dry. You can talk about waterproofing materials.

- Anti-condensation. Equipped with special fleecy layer, which is located on their inner surface. It retains moisture and prevents contact with thermal insulation. Moisture quickly disappears due to air circulation in the gap. This type of insulation must be laid with an adsorbent layer to the inside of the room. Attached using a counter-lattice.

- Vapor tight. They provide impenetrable protection to the inside of the roof insulation. Sometimes they have a layer aluminum foil, which is capable of reflecting part of the radiant energy back inside. It is laid with a ventilation gap to the insulation. Provides good protection from moisture, while maintaining heat.

- Membranes. They are modern vapor barrier materials that can prevent moisture from escaping, while letting air through. When using membranes, providing an air gap is often not necessary. This material for roof vapor barrier has gained great popularity these days.

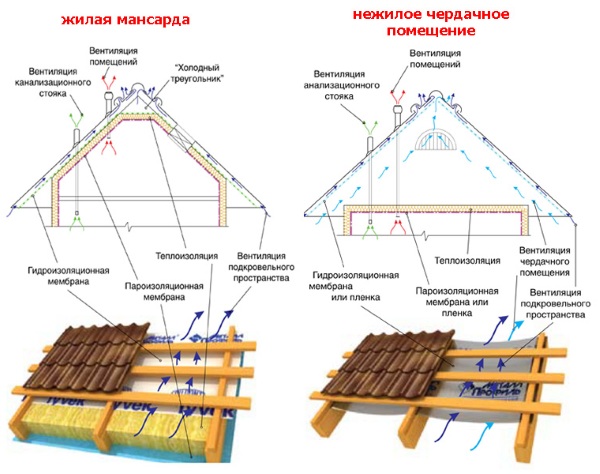

Do you need a vapor barrier for a cold roof?

The special design of such roofs does not require laying two layers: thermal insulation and vapor barrier. This saves money and construction resources. Water vapor that passes through the film ends up between the waterproofing and the corrugated sheet, from where it is removed by an air flow.

That's why main task when installing a cold roof it is ensuring good ventilation, which is ensured by creating a gap using a counter-lattice.

Cold roof installation

Do you need a vapor barrier under the corrugated roof of a cold roof? No, it’s not necessary, the main thing is to take care of good ventilation.

Vapor barrier for attic roof

The most commonly used materials are glassine, roofing felt and foil insulation. Modern membranes are also quite effective, which have proven themselves in this sector and are excellent for vapor barriers of soft roofs.

The most commonly used materials are glassine, roofing felt and foil insulation. Modern membranes are also quite effective, which have proven themselves in this sector and are excellent for vapor barriers of soft roofs.

First of all, it is necessary to seal and insulate the various structural elements. The vapor barrier is laid on and secured using a method that matches the surface material. You can read about insulating an attic roof.

Fastening to concrete, brick and metal surfaces is carried out using double-sided adhesive tape, laid with a 10 cm overlap. And it is attached to the tree with nails or staples.

CAREFULLY!

The vapor barrier film must be installed without sagging, with slight interference.

The foil film is installed with a reflective layer inside the room so that thermal energy remained inside the building. A gap is provided between the thermal insulation and vapor barrier parts for ventilation, as well as to create a warm air barrier.

Detailed diagram of the roofing pie of the attic roof

The joints of the film are taped with tape made of a material with a similar coefficient of thermal expansion. It is better to press the junctions of the foil to the wall with strips with sealant applied under them.

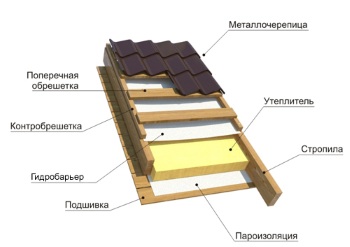

Vapor barrier under corrugated sheets or metal tiles

Metal tiles are a thermally conductive coating, so with the onset of cold weather, condensation causes irreparable damage to them. To solve this problem, it is necessary to provide the roof with proper vapor barrier and. Before choosing, you should decide what is more important: price or efficiency? Let's look at which vapor barrier is better for metal roofing:

Cheap option - glassine and polyethylene

Glassine can last a long time, while it has sufficient flexibility and low cost. However, its large mass, unpleasant odor when heated and difficulties during installation make it not the best option.

Polyethylene retains steam well and protects the thermal insulation layer from moisture. It is cheap, but polyethylene is very easy to damage. It is difficult to install it yourself. Due to its significant mass, it is difficult to install the film to the corrugated sheet using the standard method. Therefore, installation occurs to the inside of the cladding using a stapler. The film is mounted in two layers.

Reinforced film, foil, membranes

In terms of price, it is also an acceptable option. Reinforced film consists of several layers with a reinforcing fabric mesh that adds strength. Light weight and rigidity allow you to install such insulation yourself. Attached with self-adhesive tapes. A significant drawback is the lack of an anti-condensation layer, which can negatively affect the insulation.

Diagram of a metal tile roof

Which vapor barrier to choose for a roof under metal tiles? One of the best options is foil. It has low thermal permeability, which allows you to retain heat in the room, is lightweight and has sufficient strength. The big disadvantage of this material is its tendency to corrosion.

Useful video

We invite you to watch a video about the properties of vapor barriers:

Conclusion

The penetrating ability of steam is sometimes underestimated, which leads to rapid failure of thermal insulation. Therefore, it is necessary to take a responsible approach to the issue of vapor barrier and take into account all the nuances when choosing materials and carrying out work. This will ensure long term services for future construction.

Roof installation: is insulation required?

Buildings such as summer country house, barn or gazebo, do not require special insulation. Lightweight roofs can provide them with normal functioning. They will cost less, and installation will take relatively little time. The only thing that should be taken into account when carrying out the work is the possibility of subsequent redevelopment, namely, whether the attic will ever need to be converted into a living room or not.

To prevent the condensation that forms at the top, on the cold surface, from getting inside the attic, a film with waterproofing properties is placed on the rafters. Then a counter-lattice is nailed to it, a sheathing is placed on top of it, and the covering sheets, which are chosen in advance, are completed. For ventilation and removal of excess moisture, special ventilation holes are left. In the attic, dormer windows or hatch windows are made for the same purpose. If you install them in a row, in summer this room can be used as a solarium.

Significant savings in time and money are possible due to the fact that the simplified version does not require laying two additional layers, namely: vapor barrier and thermal insulation. This is precisely their main difference from insulated roofs. In addition, you can choose inexpensive materials for the waterproofing layer. The main purpose of the design is protection not from cold, but from precipitation.

Such a device can also be used in individual residential buildings, and not necessarily in the southern regions. If the ceiling between the attic and the living space is insulated in accordance with the standards for a specific climate, no additional costs will be required when installing the roof. It will provide comfortable living conditions even without this. It is only necessary to carry out high-quality thermal insulation of the ventilation equipment to protect it from the accumulation of condensation and then icing.

Choosing roof material

Types of roofing materials (tiles, metal tiles, wood, bitumen, slate).

An inexpensive micro-perforated film can be used to cover the rafters. To ensure that water flows to the center, a 20 mm sag is allowed during installation, and to evaporate moisture, a rupture is made in the waterproofing under the ridge. However, if a cheap film adheres tightly to the insulation, its waterproofing properties will be lost and it will begin to allow moisture to pass through. Therefore, if you ever convert your attic into an attic and want to insulate it, you must use a TYVEK type waterproofing membrane.

It is best to lay a profiled sheet or metal tile on the outside. Nowadays, polymer-coated steel is used for their production. Its layer protects the surface well and increases service life. For example, manufacturers of roofs coated with Colorcoat Prisma give a 20-year guarantee on it, although in reality it does not lose its quality for at least 50 years. If you value aesthetics, choose metal tiles. Outwardly, it is almost no different from its ceramic predecessor, but weighs much less.

Another type of coating for a profiled sheet, anti-condensation, significantly simplifies and reduces the cost of the process if insulation is not provided. Its structure resembles artificial felt; it consists of intertwined polyester fibers. There are many air layers between the fibers, which is why the coating can absorb large number condensate In addition, when the air is heated, excess moisture quickly evaporates. A counter-grid is not used with this installation method, as a result of which the time spent on it is halved and the cost is reduced.

For buildings without an attic: garages, verandas, sheds - especially in the case of a pitched roof, an anti-condensation coating is most suitable, since there is no need for a waterproofing film. At the same time, it muffles the noise of hail and rain, mold and mildew do not form on it, and it is easy to care for. Dirt is washed off using a hose with water.

Transparent polycarbonate sheets are of great interest to designers. They are used as inserts, and such a device makes the attic or veranda lighter. Polycarbonate absorbs ultraviolet radiation and is resistant to frost and accidental impacts. In the south, smoky materials are usually used for inserts. Moreover, the MP-20 polycarbonate sheet fits well with the MP-20 corrugated sheet and makes it possible to combine them in different ways.

All roofs for houses can be divided according to configuration into: flat, pitched. Flat, have a flat roof with an inclination angle of 3-5 degrees. These days they are used extremely rarely, since water stagnation often occurs in them. This type of roof installation is suitable exclusively for outbuildings, as well as for small-sized baths.

In turn, pitched roofs are used much more often. They, in turn, are divided into:

- (pincer);

- semi-hip gable;

- semi-hip hipped;

- multi-pincer (multifaceted).

The most popular among the above are single- and double-pitched roofs, which are often also called “cold” and “warm” due to the design of the rafter system and the roofing pie.

Cold roof construction technology

It can only be used in cases where the room has the necessary thermal insulation, including from the ceiling adjacent to the attic, or if a small room is being built.

The main difference between a “cold” roof is that it is installed directly against the wall of the house. That is, the main load will not go on the rafters, but on the room. The beams will directly support the roof, so their thickness can be adjusted from 5 centimeters or more.

The rafters are supported on the Mauerlat. Purlins, struts, racks and beams, in most cases, are not equipped, since even ordinary crossbars are quite enough to reliably hold the shape of the roof and prevent it from being beveled later during operation (due to wind and rain). The ridge purlin rests directly on the rafter legs.

A roofing pie for a “cold” roof consists of one level of sheathing, an external roof (which can be tiles, slate), vapor and waterproofing. There is no insulation layer provided, since the attic of a cold roof is not intended for use as a living space.

However, thanks to a properly designed ventilation system, the temperature inside the roof attic is 5-10 degrees higher than environment. Thermal insulation is attached to the floor of the attic, which protects the interior space of the living part of the house from cold air. Ventilation pipes are also installed here and a vapor barrier membrane is laid, which protects the house from condensation.

The construction of a cold roof is simple, so it is suitable for the construction of summer kitchens, closed gazebos, and the construction of modular block containers (which are initially insulated).

For more information on installing a cold roof under metal tiles, watch the video.

Arrangement of a warm roof rafter system

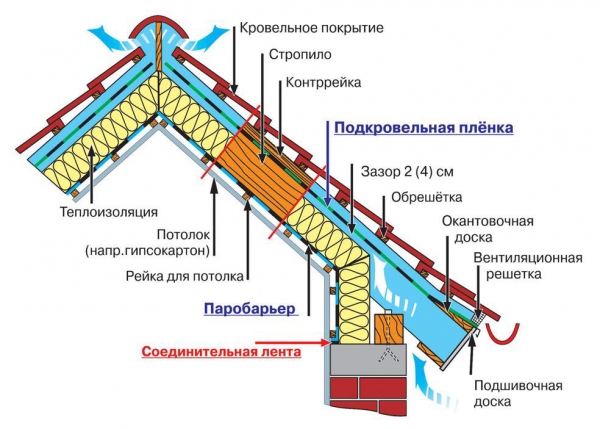

The rafter system for warm roofs is somewhat more complicated, since it involves using the attic as a living space. Most best option for this type of roof - an attic system, which allows you to get a fairly large amount of free space. The structure of the roofing pie in this case looks like this:

- roof;

- sheathing and counter-lattice;

- steam and waterproofing;

- thermal insulation (mineral wool or polystyrene foam board);

- decorative layer ( interior decoration).

The main difference between the design of the rafter system is that it is held in place by supporting

beams, as well as mauerlat. Additionally, the roof is divided into purlins and struts (for gable systems). The angle of inclination of such roofs, as a rule, is divided into two parts: at first it is about 120 degrees, then (after the last support beam) - about 35.

A fairly well-known technology for arranging roofs is the system with layered rafters. But today it is rarely used, since it requires a large amount of wood materials, although it does not make it possible to equip a full-fledged living space in the attic.

The undeniable advantages of this technology include: high-quality load distribution, adjustable roof height (the angle can easily be changed during construction). But still, roof structures with hanging rafters are much more often used.

Also in the rafter systems of warm roofs there is a so-called “wind beam”, which is responsible for the stability of the roof. The side rafter legs, as a rule, are lengthened due to wooden “fillies”, to which it is convenient to subsequently install drainage systems.

Installation of the central beam is carried out in cases where the running length of the roof is more than 7 meters. If the length is shorter, the decision should be made depending on the load on the ridge span. If it turns out to be too high, this will lead to the penetration of additional moisture and condensation into the interior of the attic, which, of course, must be avoided.

Sheathing and reinforcement strips

Counter-lattice - an additional layer of thin rafters that are used in warm roofs for installation internal thermal insulation. This type of lathing can also be attached directly to retaining strips if they are provided for in the overall design.

Installation of reinforcement strips begins with the installation of the upper retaining beam. A mauerlat is laid along the perimeter of the roof, which is tightened with ties (the beams are laid directly on the roof and secured with solid staples or studs). The fastening of the retaining strips to the main beams is carried out through metal corners(tightened with 4-6 screws).

Roof insulation and waterproofing

Mineral wool reinforcing mesh or simple polyethylene film is used as waterproofing for warm roofs. In some cases, it is recommended to install it in two layers: above the thermal insulation and below the thermal insulation. It should be borne in mind that this option is only possible in cases where a basalt mat that is resistant to moisture is used as insulation.

It is important to note one more point: waterproofing will reliably protect the roof from condensation only if it is laid between the sheathing and the counter-lattice. At the same time, it is most convenient and reliable to install the heat-insulating layer directly on internal bars(laying mats vertically between them). But it is also possible in two layers, while the inner one must be installed horizontally (depending on how the counter-lattice was installed).

In most cases, installation of sound insulation is not necessary, but if you decide to use it, then it is recommended to lay a layer behind the insulation before interior finishing (plasterboard).

Roof ventilation system

The roof ventilation system can be configured in two ways. The first one is suitable if you do not intend to use the attic for living. It is most rational to arrange traditional natural ventilation through side slopes. But keep in mind that if a warm chimney passes through the attic, cold air will accumulate in the lower part of the room. If internal ventilation is simply exhausted through the attic, cold air, as well as condensation, will form directly under the roof.

In warm roof systems, as a rule, artificial ventilation of the room is provided. Its performance is calculated based on the volume of the attic divided by 3 or 4. This system is necessary in any case, since an anti-condensation membrane is additionally installed in such roofs. And it significantly worsens the air exchange between the external and internal environment.

Instructions for laying metal tiles

It begins with the installation of the eaves strip, lower valley, and adjacent panels. Then the sheets of metal tiles themselves are laid along the rafters, which are attached to the wood base using self-tapping screws (roofing fasteners are used) and ends with the installation of the ridge element, upper valley and end strip.

For more information about installation and its main mistakes, watch the video.

The cost of installing metal tiles depends on the complexity of the work (the height of the roof, the angles of inclination) and whether it is insulated or not. On average in Moscow, the price for installation will cost 400-450 rubles per sq.m., if insulation is necessary, then the cost increases by 70 rubles per sq.m. for each layer (50 mm.). Often, in addition to installation, it is necessary to dismantle the old roof, and this adds to the cost of about 100 rubles. per sq.m.

Completion of roofing work

Work on the arrangement of the roof and roofing ends with the removal of the roof from unnecessary elements: sticks, tools, sawdust, shavings, etc. It is necessary to paint the areas where metal tiles are trimmed and cut with paint in the color of the roof - to prevent metal corrosion.

If the interior decoration of the attic is intended, it is most convenient to use plasterboard or plywood board. In order for the inner decorative layer to be absolutely smooth and even, it should be mounted on aluminum profiles (they are also attached to the counter-lattice using corners and belts). After this, you can begin installing gutters around the perimeter of the roof.

A house with a cold attic is far from uncommon in modern construction. This solution is especially relevant for outbuildings, as well as summer cottages. Often a cold roof made of corrugated sheets is also made in residential buildings, when the main area of the house is enough for its owner and there is no need to make an attic.

Installation of a cold roof made of corrugated sheets

The installation of a cold roof is advisable, first of all, for economic reasons. Firstly, you save on materials, and secondly, by isolating a large area of under-roof space from the rest of the house, you do not spend money on heating it. And thirdly, installing a cold roof is much easier than laying a full-fledged roofing pie.

This article is devoted to how to properly make a cold roof from corrugated sheets.

Installation of a cold roof made of corrugated sheets in a residential building

The design of a cold roof is very simple. The slopes do not require any insulation, vapor barrier, or, moreover, finishing. Naturally, the savings in this case are quite significant, given that the price of thermal insulation and finishing is 50-60% of the cost of the entire roof. In addition, due to the simplicity of the design, a cold roof made of corrugated sheets can be installed with your own hands without any problems.

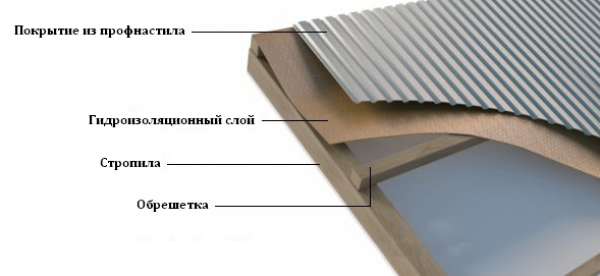

The cold roof pie consists of the following elements:

- Rafters;

- Waterproofing film or membrane;

- Counter grille;

- Lathing;

- Profiled sheeting.

Cold roof waterproofing: is it necessary?

Waterproofing a cold roof will protect the room from possible leaks and condensation that forms on the inside of the metal roofing. Since condensation is released on metal surfaces when there is a temperature difference, there is a common misconception that it will not occur if an uninsulated roof made of corrugated sheets is installed.

Naturally, such an opinion is not true, since, despite the fact that the under-roof room is not insulated or heated, the temperature inside will still differ from the temperature outside, and often quite significantly. Therefore, the answer to the question: “Will there be condensation on the corrugated sheeting if the roof is cold?” - unequivocal: “Yes, it will be.”

In this regard, it becomes obvious whether waterproofing is needed under the corrugated roof of a cold roof. The consequence of its absence will be that condensation will fall on the ceiling, increasing the humidity in the attic. This will lead, at best, to accelerated deterioration of wooden structures, and at worst, to a catastrophic decrease in the thermal insulation properties of the insulation if it is unprotected.

Installation of waterproofing film with sagging

The waterproofing membrane of the cold roof is laid on the rafters and secured with a counter-lattice, after which the lathing for installing the corrugated sheeting is installed.

If you do not intend to insulate a cold roof in the future, then you can use microperforated film as waterproofing, which costs much less than special membranes. However, it must be installed with a mandatory sag of 20-30 mm so that moisture flows into the space between the rafters, and does not moisten them, seeping through due to the capillary effect.

Vapor barrier and ventilation of cold roofs

Since microperforated films prevent the penetration of moisture from the outside, but do not interfere with the passage of water vapor, a vapor barrier for a cold attic on the roof slopes is not required. Water vapor, having passed through the film, ends up between the waterproofing layer and the corrugated sheet, from where it is removed by an air flow.

If a waterproofing film for a cold roof retains water vapor, this will lead to excessive moisture in the room and, as a result, dampness. In addition, as humidity increases, steam will condense on the film from the inside. Therefore, ordinary polyethylene and polypropylene films, as well as outdated materials such as roofing felt or glassine, are not suitable for waterproofing cold roofs.

Ventilation of a cold roof is very simple and is achieved by creating a gap using a counter-lattice: the air flow enters under the roofing through the eaves and exits through the ridge.

The presence of a counter-lattice is a prerequisite for good ventilation. It is this gap of several centimeters between the film and the sheathing that allows air flow to pass unhindered under the roofing.

Ventilation of a cold attic is carried out using ordinary dormer windows, which must be located in such a way as to ensure the passage of air flow when ventilated throughout the room. If the size of the under-roof space is large, the ventilation of a cold attic in a private house can be improved using a classic supply and exhaust circuit.

If you are planning to insulate a cold attic in the future

If a cold roof made of corrugated sheets is a temporary option, and in the future you plan to insulate it to create a full-fledged living space, microperforated film should not be used as waterproofing. The fact is that insulation cannot be installed close to it - if this is done, the film will lose all its waterproofing properties and begin to let water through.

This film must be replaced with a non-woven vapor-permeable membrane. In particular, those types of Tyvek or Dorken membranes that can be laid directly on the insulation are ideal for these purposes. They, of course, are more expensive, but their use will reduce the thickness of the roofing pie by 80-90 mm. If you already use microperforated film as waterproofing for a cold roof made of corrugated sheets, you must provide a gap of at least 50 mm between its lowest point, taking into account sagging, and thermal insulation.

In addition, vapor barrier of a cold roof converted into an insulated one is not necessary, since the steam will pass through the insulation and, without remaining in it, will be removed through the film or membrane.

Cold roof made of corrugated sheets in utility rooms

For sheds, sheds and other utility rooms, installing a cold roof made of corrugated sheets is the best option. In this case, it is recommended to use special corrugated sheeting with an anti-condensation coating.

Corrugated sheeting coated on the inside with an anti-condensation coating

This profiled sheet is coated on the reverse side with a special synthetic compound, which is similar in structure to felt. Due to the large number of small air cavities, this material can retain a fairly large amount of moisture - up to 1 liter per m2. Thus, when humidity increases, the anti-condensation coating absorbs water, which then evaporates under the influence of cold roof ventilation.

Thanks to the use of corrugated sheets with anti-condensation coating, the design of a cold roof becomes much simpler and cheaper, since neither waterproofing nor counter-lattice is needed. In addition, such material is indispensable for gazebos, verandas, canopies and other open structures, since they generally do not use waterproofing, and condensation appears no worse than in a cold attic.

Installation of cold roofing from corrugated sheets

The cold roof of a house made from corrugated sheets is laid simply and can easily be installed with your own hands without the involvement of specialists.

First, the waterproofing is installed, with sagging if microperforated film is used as it. It is fixed using counter-lattice bars nailed to the rafters parallel to them.

Then the house is sheathed. About how to make it and what step to choose depending on the brand of profiled sheet -.

Next, the direct installation of a cold roof made of corrugated sheets is carried out. If the width of the roof slopes is less than the maximum possible length of the corrugated sheet, then it is laid without any transverse joints at all, which improves the tightness of the coating. Side joints are made in 1-2 waves, depending on the slope of the roof and the grade of the profiled sheet. Read more about installing a cold roof made of corrugated sheets.

Cold roofing technology is quite simple, so its installation is quite quick. However, all wooden components of the roof must be treated in advance with special compounds that will prevent them from rotting, as well as mold and mildew.

How to insulate a cold roof?

Often, installing a cold attic is just an intermediate stage. Most cold roofs are insulated over time in order to increase the living space of the home. This is easy to do, since there is no need to remake the cold roof pie - it is, in fact, top part insulated roof pie.

In order to make an attic out of a cold attic, you just need to add a layer of insulation and finishing. If, as we recommended, you used a waterproofing, vapor-permeable membrane, rather than a micro-perforated film, as waterproofing, then the thermal insulation material is laid closely between the rafters. Then the internal lathing is made with bars of the required thickness, between which a second layer of insulation is mounted. They can also be used for finishing with wooden boards or drywall.

Insulating a cold attic using sprayed polyurethane foam

When insulating a cold attic, a layer of vapor barrier is not needed, since water vapor from inside the room will pass through the insulation and exit the roofing pie through the waterproofing membrane into the under-roof space. Therefore, before insulating a cold roof, do not forget to treat all internal wooden structures with compounds that prevent rotting.

In addition to this method, insulation of a cold roof attic can also be done by spraying polyurethane foam. This is one of the fastest and simple options, besides, this insulation is considered one of the best existing on the market. It is fireproof, has excellent heat-insulating properties, is durable, resistant to acids and alkalis, and does not rot.

In addition, insulating a cold roof made of corrugated sheets using polyurethane foam allows you to create a continuous layer of thermal insulation, in which not only will there be no cracks, but the rafters will also be covered. The only drawback of this method is the cost. Also, you will not be able to do this work yourself, since it requires expensive equipment.