Often, during construction, it is necessary to calculate in advance the required number of fasteners (hardware). How to do this? After all, building structures have different configurations and areas. In particular, there is a need to determine the number of screws for fastening profiled sheets. Possible calculation methods are given in the article.

Advantages of self-tapping screws compared to other fasteners

You can fasten corrugated sheets using various fasteners - from self-tapping screws to bolts.

Obvious advantages when using - the corrugated sheet can be attached to a structure made of any material without the need to drill holes for fastening. The self-tapping screw has a drill at the end and drills a hole and at the same time cuts threads when rotated.

A variety of design options for self-tapping screws allow them to be used for almost any combination of materials and loads. Special coatings ensure corrosion resistance of fasteners and extend service life to 45 years. The only condition is that you must use self-tapping screws designed for specific materials.

The technological advantage of self-tapping screws is most pronounced in the speed of installation. All work can be done with minimum set tools. For example, using only a screwdriver.

2. Factors affecting the consumption of self-tapping screws

The correct answer to this question is impossible without taking into account 2 main factors:

- functional application of profiled sheets

- operating conditions.

Functionally, the corrugated sheet is only an element of the enclosing structure. However, its use in this capacity is quite diverse.

Corrugated sheeting can be used as:

- roofing,

- wall material of a prefabricated building (garage, barn, hangar),

- finishing material for walls of buildings and structures,

- filling the fence span, etc., etc.

In each of these cases, it is necessary to know the number of screws, and it can vary by orders of magnitude.

Strongly influence the consumption of self-tapping screws natural conditions, in which corrugated sheets are used.

- Wind and snow loads,

- corrosion

– reasons for the increased consumption of self-tapping screws for installation.

Important! The sheet profile has a significant impact on the fastening technology, and therefore on the amount of fasteners. The more complex the profile, the greater the number of fastening points required for its reliable installation.

Rules for installing profiled sheets

There are general rules laying sheets on various designs, which will determine minimum quantity fastener installation points required for installation:

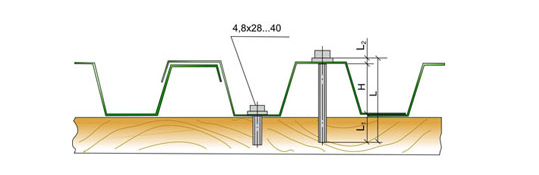

- When installing profiled sheets on the roof self-tapping screws are installed in the lower part of the profile, with the exception of the roof ridge, on which fastening is carried out through top part profile.

- When installing fences and wall cladding self-tapping screws are installed, as a rule, only in the “trough” of the wave, tightly adjacent to the plane of the underlying structure.

- In all cases, it is necessary to fasten the overlapping areas of the sheets with self-tapping screws.

- For all options for the location of the corrugated sheet, the axis of the screw must be strictly perpendicular to the surface of the profile and the fastening surface to prevent moisture from penetrating under the head of the screw. This circumstance leads to rapid destruction of the body of the fastening element and significantly reduces the service life of the coating.

Features of installing corrugated sheets on building structures

The number of screws when installing corrugated sheeting depends on the location of its installation and, as a consequence, on the method of laying out the sheets.

And if the method of laying out sheets during the construction of a fence does not cause any difficulties, then during the construction of a roof everything looks much more complicated, taking into account the different slopes and shapes of the roof slopes.

The most common options for using corrugated sheeting will be discussed below:

- roof covering;

- fence span;

- cladding of wall fences;

- walls of light buildings.

Features of installation on the roof. Calculation of the number of attachment points

The number of installation points for self-tapping screws for installing the roofing is determined by the pitch of the sheathing and the size of the sheet.

The pitch of the sheathing specifies the number of vertical fastening rows and depends on the angles of the roof slopes. When the slope angle is more than 15 degrees, the pitch is set from 30 to 50 cm.

The corrugated sheeting is attached to the sheathing in a random order through 1 wave, with the exception of the attachment points to the lower and upper tier of the sheathing - the sheets are attached to the first and last beams in each wave, since the wind load is concentrated in these areas.

Important! The most rational from the point of view of reliability and load distribution is the checkerboard arrangement of the points of attachment of the sheet to the sheathing.

The density of attachment points of the main body of the sheet is at least 4 per square meter. The points should be spaced as evenly as possible both across the width of the sheet and along its length.

It is necessary to take into account that the sheets on the gables and areas of longitudinal overlaps are attached to each beam of the sheathing. In the case of using continuous sheathing, fastening is carried out at intervals of at least 50 cm along the length of the sheet.

Based on the above considerations, in general, the approximate number of screws for attaching one sheet of corrugated sheeting to the roof can be determined by the formula:

N = n × 2 + m × 2 + S × 4

m – number of sheathing beams along the length of the sheet,

S – area of the profiled sheet in square meters.

Calculation of the number of installation points for self-tapping screws during fence construction

When building a fence, the attachment points of the sheet are located on horizontal logs. Their number is determined by the number of logs and the value of wind pressure in a given area.

At low wind speeds, it is advisable to install self-tapping screws at 3 points along the width of the sheet - at 2 points along the edges (in the overlap area) and in the center. That is, to fasten 1 sheet with 3 joists, you will need 9 self-tapping screws.

With predicted significant wind loads, it is necessary to strengthen the reliability of the fastening. It is recommended to screw self-tapping screws into each wave along the length of the lag. The total number of attachment points is calculated by the formula:

m – number of lags.

Consumption of fasteners per sheet of corrugated sheets on facades and wall fences.

When using corrugated sheets for cladding facades, the sheets are mounted on a special frame. The frame material may vary. Wooden blocks are most often used.

Self-tapping screws are installed through the wave. The condition of mandatory fastening in places of overlap must also be observed. The number of rows of attachment points depends on the frame design.

Calculation of the maximum number of fasteners for mounting 1 sheet is made using a formula similar to the calculation of fastening points on a fence:

where n is the number of waves on the sheet,

m – number of rows of attachment points.

How many of them are needed? When buying, it is easier to weigh than to count.

The values of the number of fastening elements obtained using the formulas do not take into account the installation of various elements of the roof covering, such as structures:

- adjacencies,

- snow retention,

- pipe aprons,

- strips of cornices and gables.

For an approximate calculation of the total number of fasteners, use

The data obtained in practice is that 8-9 pieces of self-tapping screws are consumed per 1 m2 of profiled sheet.

- The useful area of the profiled sheet is calculated. To do this, the overlap area is subtracted from the total area. The overlap size is assumed to be 15-20 cm.

- The resulting area is multiplied by 9. The approximate number of fastening elements per 1 m2 is obtained.

- The result is multiplied by the number of square meters of roofing.

The amount of fasteners will be quite large. How to calculate it when purchasing? Of course, no one counts the specific number of screws. Each screw has an exact weight. Consequently, the weight of any number of products is known. For convenience, manufacturing plants produce fasteners in packages of 100 to 6,000 pieces.

Conclusion

In counting the number of screws for fastening profiled sheets on various building structures there is nothing complicated. Common sense and practical experience of previous generations are the basis for the correct approach to this problem.

What screws are used to attach corrugated sheeting to the fence?

A fence, as an enclosing structure, most clearly shows the level of well-being of the owner and his aesthetic tastes, so many nuances depend on the choice of material.

Corrugated sheeting can be the best solution, as it is reliable, durable, and attractive. Due to its advantages, it has gained popularity as the main material for fencing.

Its main advantages include:

- wear resistance;

- is not exposed to precipitation and wind loads, temperature changes, because it is made of a thin high-quality metal alloy;

- moisture resistance, resistance to chemical corrosion, acid-base precipitation;

- increased strength, lightness;

- simple installation technology, ease of work, does not require special equipment and tools, only a screwdriver will be enough;

- economical, low cost, no additional costs required during operation.

Characteristics and types of self-tapping screws

To fasten corrugated sheets, fasteners are used, called a self-tapping screw or a self-tapping screw, which is a steel rod with an external thread and a head. He has the ability cut threads yourself in any building material

, into which it is screwed without pre-drilling holes.

To fasten corrugated sheets, fasteners are used, called a self-tapping screw or a self-tapping screw, which is a steel rod with an external thread and a head. He has the ability cut threads yourself in any building material

, into which it is screwed without pre-drilling holes.

The main distinguishing feature of a self-tapping screw compared to screws and screws is that the thread is made along the entire cylindrical surface of the rod. It has high strength, which is acquired as a result of thermal hardening during the manufacturing process. According to GOST instructions, all types of self-tapping screws are certified according to international standards.

The material used for making fasteners is galvanized carbon or high-quality stainless steel; sometimes it is coated with polymer paint of various colors.

The connections of the fastening elements are load-bearing because they absorb the bulk of the loads.

The range of self-tapping screws intended for fastening metal profiles is quite wide; they have different lengths, diameters and head shapes. They are produced with a diameter from 4.0 to 6.5 mm, a length from 19 to 250 mm with a head of round, semicircular, spherical, cylindrical, hexagonal shape. Splines are made cruciform, straight, hexagonal. The choice of tool used to install the fastener depends on the shape of the slot.

Watch the following video to learn how to choose the right screws:

Material consumption

Calculation of the consumption of screws for metal can be carried out using various methods. To know how many fastening elements are needed, you need to calculate the perimeter of the fence that encloses the area, taking into account the width of one sheet of corrugated board, and know the dimensions of the fence, in particular the height. The calculation is carried out using the formula:

N s = R s /b prof, Where

- Rz – fence perimeter, found by adding the length and width values on all sides, m;

- b prof – width of the corrugated sheet.

When installing a fence using the “end-to-end” technology, the installation width of the sheet is taken into account, taking into account the size of the “overlap”. A separate sheet is attached to the frame with 5-6 self-tapping screws; in some cases, auxiliary ones are screwed into the lower part of the wave to increase strength.

The standard value is the consumption, the value of which is 9 pieces per sheet. In this case you need to find the total number of corrugated sheets and multiply by 9.

Where and how to screw in self-tapping screws

There are no special requirements for fastening the fence according to SNiP and GOST. The distance between the screws is equal to two waves of the flooring, which ensures the reliability of the design. The stability of the fence as a whole depends on the correct installation of the supports.

Ordinary self-tapping screws help attach the corrugated sheet to wooden joists, and self-tapping screws with a drill - to the metal purlins. It is more expedient to fasten the corrugated sheet through the waves that most closely fit the purlins.

Self-tapping screws must be screwed in using a screwdriver that has a torque limiter. At correct installation the rubber gasket will protrude approximately 1 mm from under the washer.

Using an awl, you can make a small indentation in the place where the self-tapping screw is screwed in. The part is set to “position”. Using careful, confident movements, the element is rotated until it is deepened and secured, then the force is increased. In order not to deform it, the speed decreases towards the end of the process.

The installation of the fence is carried out in stages, but first it is necessary to preparatory work, clear of vegetation. The main stages include:

- Supports are installed along the perimeter of the fence in open recesses.

- Horizontal transverse logs made of metal products or wooden beams in several rows.

- The corrugated sheet is screwed onto the joists, starting from the end. Separate sheets must overlap the wave of the sheet that was installed earlier; the joints are treated with a water-resistant sealant for additional waterproofing.

- Corner joints and ends are covered with special strips and strips; the ends can be treated with an anti-corrosion compound to extend the life of the fence.

Self-tapping screws are secured together with rubber pads and match the color of the fence. They must be screwed orthogonally to the surface of the sheet to avoid distortion. After finishing the fastening, the places where the elements were screwed in must be primed or covered with enamel of a suitable color.

What else can you use to secure the profiled sheet?

In addition to self-tapping screws, other types of fastening are quite suitable and are also effective:

- Rivets create a permanent connection between corrugated sheets and solid materials. They are made of two types of metal: the leg is made of steel, and the cap is made of aluminum, there are painted and unpainted. The diameter of the rivets ranges from 3.2 to 6.5 mm. The sheets are fixed using a special gun. The average number of rivets used per 1 m of coating is 6-8 pieces.

- Screws, rods, having a sharp thread and head. They are made of wood and metal. Metal connections use fine thread screws. They create a detachable connection between surfaces. A hole is drilled on the surface of the corrugated sheet, where a screw is screwed in, the thread is inside.

Regardless of the type of fastening, the connection will be reliable.

Self-tapping screws for corrugated sheets

The self-tapping screw is indispensable in construction work. It is also widely used in repairs and at home. It is a universal fastening connection, which is used when installing metal tiles and metal profiles when carrying out roofing and facade works. For these purposes, special self-tapping screws for corrugated sheets are used, which are galvanized screws or have a colored polymer coating.

Colored polymer is used to protect fasteners from corrosion. You can also choose self-tapping screws according to the color of the corrugated sheet, making them invisible.

Self-tapping screws are used when working with metal and wood, and:

- for metal they are used with frequent threads (B in the picture);

- for wood - with rare (in the figure - A).

Self-tapping screws: A - for wood, B - for metal

The set of drill-shaped self-tapping screws for corrugated sheets includes neoprene washers. They are necessary to protect the roof from moisture entering the roof space.

There are self-tapping screws with a drill-shaped or sharp tip, with a countersunk, semi-countersunk, semicircular, cylindrical, spherical and hexagonal head. They are made with various types slots - straight, cruciform, figured, hexagonal and asterisk.

Since the main materials used for roofing are metal profiles and metal tiles, the demand for metal screws for corrugated sheets is constantly growing. They are the main means of fastening, so their choice must be taken very responsibly. Especially when it comes to buyers who construction work or do the repairs yourself.

Scheme for fastening a self-tapping screw for corrugated sheets

Which screws are best to choose for corrugated sheeting?

Self-tapping screw for drywall

The choice of self-tapping screws is now very wide. They fasten structures made of metal, plasterboard and wood, and each type has distinctive features. Metal fasteners are more expensive than self-tapping screws for wood and drywall.

Before buying self-tapping screws for corrugated sheets, you need to carefully select the manufacturer, since using a low-quality self-tapping screw can lead to rust.

A self-tapping screw that meets quality standards is the key to the reliability of the entire structure. Manufactured by modern technologies, it can last 50 years.

When working with corrugated sheeting, you need to know how to secure it firmly and securely without damaging the material.

How to fasten corrugated sheets with self-tapping screws

For roofing

The technique for fastening corrugated sheets with self-tapping screws when performing roofing work is as follows:

- First you need to properly frame the roof, since the durability of the entire structure depends on this.

- The choice of sheathing pitch is influenced by the type of roofing corrugated sheeting and the angle of inclination of the roof.

- After completing the preparatory stage, we proceed directly to fastening the sheets with special roofing screws.

The main fastening element of the corrugated sheet should be from 190 to 250 mm long with a diameter within the range of 4.8 ÷ 6.3 mm. The pace of work and the quality of installation are positively influenced by the use of a hexagon-shaped screw head. Such self-tapping screws are easily tightened with an electric drill with a soft start or a screwdriver.

Self-tapping screws for roofing

The length of the self-tapping screw is selected so that its thread is 3 mm. longer than the roofing material packages that are connected with it. Sometimes sheets of corrugated sheets are fastened to each other using combined rivets (for example, a cornice overhang).

When working, the question often arises: how many screws per sheet of corrugated sheeting should be used to make the fastening reliable and durable? One sheet is usually attached using 6 ÷ 8 self-tapping screws, if this is a straight section of a standard roof slope. But in order to reliably withstand wind loads, it is desirable to increase the number of fasteners closer to the ends of the sheets.

For walls and fences

Another type of work on the use of corrugated sheeting is its fastening to the wall of a building or use as a fence. Self-tapping screws with a press washer are used as self-tapping screws for a fence made of corrugated sheets, which come with a sharp tip and in the form of a drill.

Self-tapping screws for fastening corrugated sheets: 1 - up to 0.9 mm, 2 - up to 2 mm

They are also used with a countersunk and semicircular head. Sometimes aluminum blind rivets are used.

When building a fence, sheets are attached to profile pipe galvanized or colored self-tapping screws with a rubberized washer at the rate of 5-6 pieces per sheet of corrugated sheeting.

If increased strength of the fence is needed, then each wave of corrugated sheeting is secured with self-tapping screws.

The fastening of profile sheets when installing profile wall decking is carried out using self-tapping screws with a sealing gasket through the wave into the corrugation of the lower edge. Vertical joints of sheets are secured with special rivets.

Weight and price

The weight of the self-tapping screw for corrugated sheeting depends on its size and is measured in kilograms per 1000 pieces. One thousand self-tapping screws weigh from 18.5 to 41.67 kg.

It is worth mentioning in a separate line the prices for hardware products used for installing metal corrugated sheets. With a galvanized head made of self-tapping screws for corrugated sheets, the minimum price was fixed at 1.8 rubles. per piece, maximum - up to three rubles.

A screw with a polyester coating - from 3.2 rubles per piece, having a polymer protective coating with a color according to the PAL table - from 8.5 rubles.

To install a corrugated roof, it is best to use self-tapping screws. A self-tapping screw is a special rod which is made of steel.

It has an internal thread, as well as a large head that tightly fastens the corrugated sheets.

In order to firmly secure the corrugated sheet You must use the correct size screws. To attach corrugated sheets to beams, it is best to use self-tapping screws, the length of which is 32 millimeters. When attaching sheets of corrugated sheets to each other, you need to take self-tapping screws 25 millimeters long.

Self-tapping screws are produced made of fairly strong carbon steel, which ensures high level strength and durability of roof fastening. After production, self-tapping screws undergo special tests, which ensures a high level of structural strength.

Experts believe, which when attaching a roof made of profiled sheets should be:

- 300 millimeters

- 500 millimeters.

Self-tapping screws can attach a sheet to a wooden sheathing, as well as fasten them together. When installing a roof made of profiled sheets, on average, 6 to 8 screws are spent per sheet.

Self-tapping screws for profiled sheets consist of a hex head, a drill, a sealing washer and a thread. The hex head makes screwing in much easier. Using a drill, high-quality fastening is made profiled sheet to a metal profile.

The sealing washer gasket is made of neopreon rubber. Thanks to this manufacturing material, it is possible to tightness of fastening.

The basis of the sealing gasket is artificially modified rubber, which allows the self-tapping screw to self-polymerize upon contact with the surface of the profiled sheet.

Self-tapping screws for roofing are sold in boxes. There are a thousand screws in one box.Depending on the size of the self-tapping screw, the weight of one box can range from 18.5 to 42 kilograms. The diameter of the screws can be from 4.8 to 6.3 millimeters.

In order to correctly calculate the consumption self-tapping screws, it is necessary to use the corrugated sheet layout diagram. For example, if a profiled sheet is used to install the roof, the width of which is 100 centimeters and the length is 122 centimeters.

When calculating self-tapping screws, it is necessary to take into account and the fact that they need to be attached to the outer support, on each wave, and the intermediate ones - through the wave.

The sheets are fastened with screws to each other, taking into account a distance of 100 centimeters from the support. The support pitch can be 25, 50, 100 centimeters. When calculating self-tapping screws, the number of sheets is multiplied, and extreme hardware is added.

When calculating self-tapping screws, it is necessary to take into account the percentage of scrap. As a result of the calculation, it turns out that one square meter is obtained from 6 to 9 screws.

For example, if a profiled sheet is used for the roof, the width of which is 110 centimeters, the length is 80 centimeters, and the pitch of the sheathing is 50 centimeters, then the screws will be attached every 50 centimeters. In this case, taking into account the wind side, 20 screws will be required.

In order to properly install a corrugated roof, it is necessary not only to calculate them correctly, but also to install correctly. The surface of the corrugated sheet should be in clear contact with the sheathing.

This will ensure a strong and high-quality fastening. To ensure that the screws do not deteriorate during roof installation, you must use a drill or screwdriver to tighten them.

And also watch a video on how to choose screws:

Corrugated sheeting is a widespread type of roofing covering, which is popular mainly because of its technical characteristics, aesthetic appearance, affordable cost, etc.

For high-quality fastening of corrugated sheeting, you will need special fastening materials - self-tapping screws, which are worth talking about.

About the technical characteristics of fastening material

As a material from which self-tapping screws for installation are made metal roofs, as well as for wall fastening of corrugated sheets, carbon steel grade C1022 is used.

In accordance with GOST, the surface of the fastening material in question may have a zinc coating in the range of 12.5-15 microns.

Zinc coating is used in self-tapping screws to impart anti-corrosion properties.

Paying attention to the fact that fixing corrugated sheets using self-tapping screws involves the impact of loads, all batches of this fastening material are thoroughly tested for tensile strength, while the normal value is considered to be 102 kg/cm (most manufacturers of self-tapping screws prefer to give a higher value, reaching 170 kg/cm. ).

The design of the self-tapping screw is often the same: the self-tapping screw is a screw-drill having a semicircular, hexagonal, or countersunk head.

Self-tapping screws for corrugated board fences differ from roofing screws with a smaller thread pitch.

In turn, the screw head is painted in a color identical to the color of the corrugated sheet being installed.

Also, the head of the self-tapping screw may have a polymer coating.

Essentially, the drill is the lower part of the self-tapping screw.

Due to this, additional drilling of holes during installation work is avoided.

The self-tapping screw can be screwed in manually, or you can use an electric tool for this purpose - a drill with the required attachment and soft start, or a screwdriver (in the case of a power tool, installation of metal sheets is significantly faster).

In addition to this, the self-tapping screw for installing corrugated sheets is equipped with a washer made of neoprene rubber.

Rubber in this case plays the role of a hermetic material that protects the joints from moisture.

The washer is pressed against the working surfaces of the corrugated sheets using a standard press washer or EPDM, supplied in the kit.

It is worth noting that the EPDM washer has a number of positive qualities, the main one being elasticity.

When choosing self-tapping screws, you need to pay attention to the following:

- zinc coating;

- type of tip;

- polymer coating;

- presence of a washer;

- required product length;

- the presence of a neoprene layer under the washer.

How to make the correct calculation of fasteners

Correct calculation in this case is necessary in order to protect yourself from the short service life of corrugated sheeting.

Also, the correct calculation will come in handy if there is a desire to save money on fasteners.

Calculation features

For example, let’s take a profiled sheet whose width is 1000 millimeters and length is 12,200 millimeters.

Please note that the exact size of the sheet of roofing material is very important!

The corrugated sheet is fixed to the outer supports with each wave, and also through one wave - to the intermediate ones.

The sheets are fastened to each other using self-tapping screws at a distance of 1 meter from the support in increments of 250, 500, 1000 millimeters.

The lower self-tapping screws are calculated, resulting in a result of 6-9 units per 1 m 2.

Dimensional accuracy during calculations is essential.

Technique for fastening corrugated sheets

The durability of the roofing covering is closely related to the correct execution of the sheathing.

Thus, it will be necessary to perform the correct calculation of the sheathing pitch.

The pitch of the sheathing should include the angle of inclination of the roof and the type of corrugated sheeting used.

Be sure to use a vapor barrier film.

Fixing sheets of material should begin with high-quality preparation.

Roofing screws for corrugated sheets, as a rule, have a section thickness of 4.8-6.3 millimeters.

The length range ranges from 19-250 millimeters.

The speed of work, as well as its quality, depend on whether the screw head has a hexagonal shape.

If the screw is hexagonal, then the speed and quality of work on fastening sheets of corrugated sheets is significantly accelerated due to the possibility of using a power tool in the form of a drill or screwdriver.

A lot also depends on the correct selection of the screw length.

The threaded part of the self-tapping screw should be 3 millimeters greater than the width of the surfaces that are connected.

Sometimes you can use combination rivets to connect roofing sheets.

The neoprene washer, supplied complete with a self-tapping screw, plays a protective role, since it makes it impossible for moisture to enter the under-roof space.

At the stage of calculating self-tapping screws, the point is taken into account that one sheet of corrugated sheeting will require 6-8 screws (in the case of installing ordinary roofing corrugated sheeting).

Closer to the end part of the sheet, the number of screws increases for better protection from the wind.

The fastening pitch should not be less than 500 millimeters.

The procedure for attaching profiled sheets is worthy of consideration.

Materials and tools:

- Bulgarian;

- screwdriver;

- roulette;

- lacing;

- level;

- nails and hammer;

- stapler and staples.

Sequence of work:

How much do self-tapping screws cost?

The minimum cost of self-tapping screws with a galvanized head is within 1.8 rubles per unit of product, while the maximum price for the product in question reaches 3 rubles.

A self-tapping screw with a polyester-coated head will cost 3-3.5 rubles.

Imported polymer-colored self-tapping screws with a protective coating have a retail price of about 8.5 rubles per piece.

When performing calculations and installing profile sheets, you should carefully and attentively pay attention to everything related to roof construction.

Otherwise, there is a risk of getting a short-lived work result, and, consequently, unnecessary financial costs.

Watch the video about choosing screws.