Any building needs external decoration. This will help, firstly, to decorate the outer walls of the home, and secondly, to make living in such a house more comfortable. Let's find out how to choose the right finishing material for the exterior walls of your home.

Types of external finishing materials for walls

The choice of material for exterior finishing should be focused on achieving several goals at once:

- attractive building design;

- sound, hydro and thermal insulation are the most important performance characteristics, without which any finish loses its practical meaning;

- efficiency.

So, all the numerous types of exterior decoration can be reduced to the following several points:

- Plaster. External walls are simply covered with a layer of plaster, which allows you to level the walls and create a uniform coating for painting. This material is for facade works can be gypsum or cement. The second option is cheaper, but less durable, since it has better adhesive properties and also allows moist air to pass through, preventing the walls from becoming waterlogged. At the same time, any plaster is the most in a simple way finishing the house, although labor-intensive (all work is done manually).

- Siding. Siding is qualitatively different from plaster - it allows you to install such panels yourself, because their installation is very simple. It can be metal, vinyl (PVC), wood and even cement (the latter is used for the base). Finishing material siding for external walls of a house has excellent value for money. It has many advantages: it repels dust and dirt, does not fade in the sun, and is itself an environmentally friendly material.

- Facing brick. It is the choice of those who want to make their home warmer. This material has very low thermal conductivity. This brick is frost-resistant, reliable, strong and durable. And the design of this facing material can imitate any natural materials, have a smooth or embossed structure, and various patterns.

- Artificial and natural stone. Their appearance is almost identical, but their properties are different. Natural stone is much more expensive, and its installation is more labor-intensive. At the same time, a house decorated with natural stone looks noble and even majestic. Artificial stone is suitable for buildings with a less powerful foundation, and here you are not limited in the choice of colors and textures.

Choosing the right materials for the exterior of your home is a very important task. Currently, there are many options that have differences among themselves, but they are all united by a common goal - creating a beautiful and reliable coating. Indeed, the choice of cladding for exterior work should not be based only on the decorative component; an important parameter is the protective properties of the product.

Finishing materials for the exterior walls of a house should be selected based on the characteristics of the surfaces. Buildings can be constructed from various products; accordingly, the resulting foundations will have different characteristics. Thus, objects made of aerated concrete blocks have high vapor permeability, so facing products should not interfere with vapor exchange.

There are two main groups of division of building facades:

- By type of coverage. This includes surfaces that were laid in various ways. These can be dry and wet options. The former involve the use of mechanical fasteners (frames, screws, nails), while the latter are created by applying solutions.

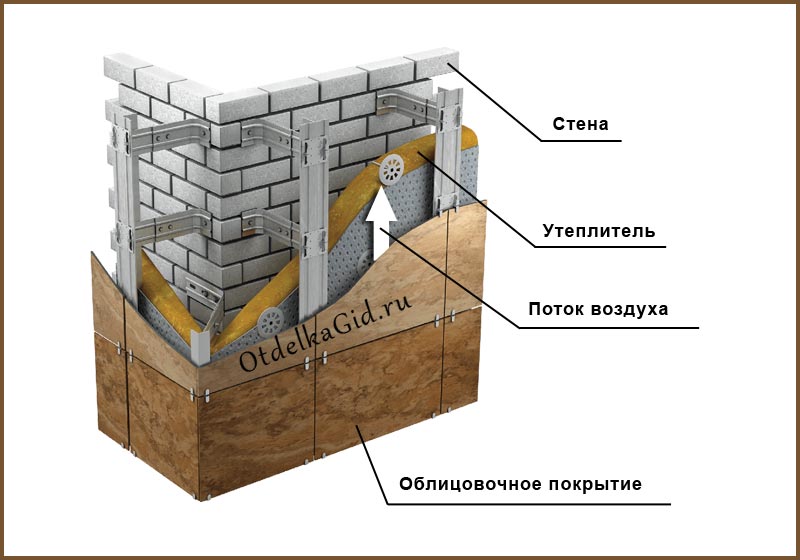

- By the presence of a gap. There are two technologies that differ in the presence or absence of a gap between the base and the constructed covering, so the facades can be ventilated or non-ventilated.

A ventilated facade is characterized by the presence of a gap between the wall and the finishing material

A ventilated facade is characterized by the presence of a gap between the wall and the finishing material Types of materials

The choice of material for finishing the outside of a house is of great importance. The main factors that you should pay attention to are the combination of advantages and disadvantages, as well as installation technology.

Natural and artificial stone

This material is divided into two large varieties. The first includes natural, natural options that have a unique decorative effect. Such products are rarely used for complete cladding of the facade; this is a very expensive pleasure. Therefore, decorative imitation is used much more often. This option is not inferior in its visual qualities to the previous one, but its cost is quite affordable. A feature of artificial parts is their low weight, which does not place a large load on the building.

The materials have similar advantages:

- Long service life. Of course, natural elements are considered more durable, but analogues are not much inferior, because tens of years is an impressive period. But to obtain such an impressive result, you should pay attention to choosing truly high-quality products.

- Unique appearance. It’s hard to argue with this statement; every detail is individual. This is why the outside of the house always looks exclusive.

- Completely safe for health. Many people believe that this parameter should be the last thing to pay attention to; this is wrong. Both natural and artificial facing materials are completely environmentally friendly. Naturally, products must have the necessary certificates.

- Impact resistance. The stone surface can withstand all the vagaries of nature, as well as various types of mechanical loads.

We cannot ignore the disadvantages:

- High price. This applies more to natural products, but even artificial variant significantly exceeds the cost of other types of facade materials.

- Decorating the exterior of your home will require some experience. This is explained by the fact that fragments (especially natural ones) must be placed strictly according to the rules.

Finishing the facade of a house with stone - durability and exclusivity

Finishing the facade of a house with stone - durability and exclusivity Installation is carried out in two ways, which differ radically from each other:

- Fixation directly to the base. For this, a special glue is used, which is evenly applied to the parts and to the surface. The main thing is to accurately carry out the preliminary markings.

- Laying on the lathing. The method is to fasten it with self-tapping screws.

Which method is better depends on the product chosen.

Note! Currently, flexible stone has appeared on the construction market. It consists of thin sheets with an applied imitation and allows you to quickly decorate the outside of a house.

Brick

Brick for cladding includes materials for facade finishing, which differ significantly in the included components and production method. Each of the existing options has its own characteristics and visual design.

Brick cladding - attractive appearance and reliability

Brick cladding - attractive appearance and reliability The most popular types of bricks are:

- Clinker. Such products are obtained by pressing and firing special types of clay. Among the available advantages are strength, durability and excellent decorative look. It is because of this, as well as the production method, that the products are quite expensive. The parts have significant weight and put a serious load on the walls.

- Ceramic. This material is quite popular for finishing the facade of a house. The fact is that it costs significantly less than the previous option, and has good characteristics. You should also take into account the problems that you may encounter: not entirely accurate geometry of the parts, the need to carefully select the composition for installation and possible errors during installation. The elements also strongly absorb moisture.

- Hyper-pressed. A bit like ceramic brick, but better technical properties. In addition to resistance to various influences and the correct geometry of the fragments, the material has a wide range. But you need to pay attention that the products create a load on the surface due to weight and change color over time.

- Silicate. Most cheap option, the most accessible among other varieties. This façade material has properties that make it possible to obtain a reliable and durable coating, but the product is hygroscopic and has little decorative choice.

The technology for installing facing bricks requires appropriate experience. There are two methods that allow you to obtain a ventilated or unventilated façade. Special attention is given to strengthening the masonry through additional reinforcement or wire laid at the seams.

Plaster

Plaster is considered the cheapest among all finishing options. There are several varieties that differ in the type of final coating. Such materials have a number of advantages:

- Aesthetics. Of course, to obtain a visually attractive surface, you will have to try, because the mixture, especially with a decorative effect, requires adherence to application technology. The outside of the house can be painted multiple times.

- Ease of use. Naturally, there are certain nuances, but general principle The job does not require any special experience.

- Excellent resistance to various influences.

All possible shortcomings largely depend on non-compliance with the installation technology; it is because of this that cracks and peeling appear.

But the choice of a suitable composition is also of great importance. The following plaster options are considered the most popular:

- Mineral. The most popular mixture, which has a low price. It has a set of excellent characteristics, but is not always suitable for facade decoration. The fact is that such products have poor elasticity; this is not very good even for buildings that were erected a long time ago.

- Acrylic. It has the necessary elasticity and durability, but is a material with low fire resistance. Many craftsmen note that the resulting surface becomes dirty quite quickly, which significantly worsens the appearance of the house.

- Silicone. This option is much better than the previous ones; its properties and long service life make it almost ideal. But the very high price makes you think about the advisability of using it.

It should be taken into account that such external finishing materials must have a special mark indicating their suitability for cladding facades. There are also compositions that are designed for different types of base. For example, for aerated concrete there is a mixture that takes into account the high vapor permeability of such surfaces.

Plaster on walls can be applied manually or by machine. The bottom line is that the solution is laid in portions, after which it is carefully leveled. To avoid cracks, the coating is reinforced. This option also allows you to create surfaces with an additional layer of insulation.

Siding

Siding appeared on the construction market relatively recently, but has already become one of the most popular products for outdoor work. Besides long term services, products are distinguished by a wide range and the possibility of quick installation. Due to the use of the frame method, the resulting space is ideal for laying insulation.

Siding - a variety of options and ease of installation

Siding - a variety of options and ease of installation The following types of siding are currently available:

- Vinyl. This material for the facade of a house is made of PVC and allows you to create an imitation of wood, stone or brick. It is due to this that the popularity of this option remains very high. Although there are a number of other advantages: long term service without loss of properties, light weight and resistance to environmental influences.

- Metal. Can be made of aluminum or steel. The latter is used most often to sheathe the outside of a house, since the aluminum variety has a high cost. This material has excellent performance qualities and virtually no disadvantages.

Note! Analogs of siding are considered to be lining and block house, which are also used for work outside the building.

Decorating a house with siding is quite simple. The technology is as follows:

- The process begins with careful preparation of the base. It includes the elimination of all defects and coating with antiseptic compounds.

- The main activity is the construction of the frame. It is mounted from metal profile or wooden beam. If necessary, a layer of thermal insulation is laid.

- The panels are laid in a given sequence. Fixation is carried out through a locking connection and hidden fasteners.

Additionally, special overlays and profiles are used, which give the coating a finished look.

If it is necessary to increase work productivity, then siding is successfully replaced with corrugated sheets, which are sheets of different sizes.

Sandwich panels

These finishing materials for facades are classified as composite; they are based on a multilayer structure. That is, between two protective sheets, one of which acts as the front decorative part, there is the required number of layers of thermal insulation.

Finishing with sandwich panels - high thermal insulation and durability

Finishing with sandwich panels - high thermal insulation and durability Product advantages:

- Insignificant weight even taking into account the thickness of several centimeters.

- There is no need to additionally insulate the building.

- Resistance to temperature changes and precipitation.

- Durability.

Naturally, the price of the products corresponds to the quality. Such sheet materials, like siding, are installed by creating sheathing. To simplify the cladding, there are thermal panels that can be attached directly to the base.

The development of modern building materials technology makes it possible to build cheaper and faster. Frame-panel and monolithic houses, buildings made of foam concrete and wood concrete, which until recently were perceived as exotic, are now becoming classics of the genre.

Oddly enough, but the most close attention potential developers are not focused on construction technologies, but to new materials for home decoration. And this is understandable, for the vast majority it is not enough to build the box of a building; you also need to be able to present the goods face-to-face or make a very precise and expressive decoration of the house.

The most popular new finishing methods

Traditionally wide range materials for finishing a newly built building are divided into several large groups:

- Decorative materials for interior finishing work. This also includes floor and ceiling coverings, wall finishing materials for auxiliary premises;

- Facing and protective coatings used in finishing the facade of a building;

- Coverings for bedrooms and children's rooms;

- Universal materials based on ceramics, composites and plastics.

For your information! Most new materials and coatings represent further technological developments of traditional finishing methods.

Most manufacturers follow this approach to developing new materials for two reasons. Firstly, it is easier and faster to overcome a person’s psychological barrier to the perception of new materials. Secondly, a modified product is much easier to sell than a completely new product.

Traditionally, the development of new materials proceeds in three directions:

- Getting a new look. For example, most of today's new wallpapers have such a range of paints, patterns and colors that were previously simply technically unavailable for production;

- Improvement of old finishing characteristics. With the introduction of new technologies for the production of ceramics and porcelain stoneware, the design, quality and durability of floor and wall tiles have increased by an order of magnitude;

- Increasing the safety and environmental friendliness of coatings, especially for children, people suffering from allergies and intolerance to certain groups of chemical compounds. Demand for new, safer finishing options is growing much faster than for coatings with unusual appearance.

The bulk of new finishing materials have emerged through the widespread use of gypsum mixtures, acrylic and polyurethane resins, and the production of updated types of ceramics and compounds. Technologies producing materials for exterior decoration of houses have received the greatest development.

New technologies and materials for facade finishing.

Truly innovative in the cladding of facades and external walls was the emergence of new building mixtures for producing decorative plaster and the introduction of a new principle of surface-mounted finishing.

New plaster and paint coatings

Decorative plaster based on acrylic resins and many different marble or calcite fillers made it possible not only to change the color and texture of the walls, but also to give them a new look through imitation natural stone or the formation of a certain surface topography. This coating practically does not fade in the sun, is not afraid of rain and frost, and if the application technology is followed, it can stay on the walls for more than ten years.

The disadvantages of plaster materials include the high dependence of the quality of new coatings on the qualifications of the plasterer; in addition, most of the work has to be done manually, especially at the stage of forming the texture of the walls.

Important! A real discovery in the field of finishing facade walls was the emergence of new water-soluble acrylic, water-based and water-dispersed paints, which have a colossal number of new shades and colors.

With their appearance, the outer walls and facade of the house can be painted in the most exquisite tones and colors. In the vast majority of cases, new paint and varnish materials for the exterior of the house made it possible to give old and gray concrete buildings a fresh, updated look with minimal effort.

Decorating external walls with hanging decor

With the introduction of frame finishing technologies, it became possible to radically change the appearance of buildings, giving the walls a completely new look. For example, the use of thermal panels with glued porcelain stoneware or imitation tiles for finishing natural stone makes it possible to give an old cinder block building the appearance of ancient masonry made of natural stone, facing brick, or even very accurately imitate wooden walls from timber or rounded logs.

Similar results in finishing can be achieved by cladding building facades with more durable panels of plastic and metal-plastic siding, a wooden block house and even new modified lining. Unlike thermal panels, new plastic and wooden cladding panels are easier and cheaper to install, therefore they are most often used in combination with new thermal insulation coatings.

In addition to hanging decor, new ceramic facing materials are increasingly being used to decorate walls - bricks and tiles made of porcelain stoneware and hyper-pressed mixtures. The new type of finishing is cheaper than traditional facing bricks, and in terms of durability and appearance not inferior to him.

Most of the new technologies are, in fact, universal and are used in the development of new materials for interior decoration premises.

What's new in home interior decoration

Most of the innovations in interior decoration concerned the development and use of new finishing mixtures, the use of plasterboard and MDF panels for wall repairs, the use of porcelain tiles for floor finishing and the installation of self-leveling floors. In fact, most new products are adapted for interior works already known materials for exterior finishing.

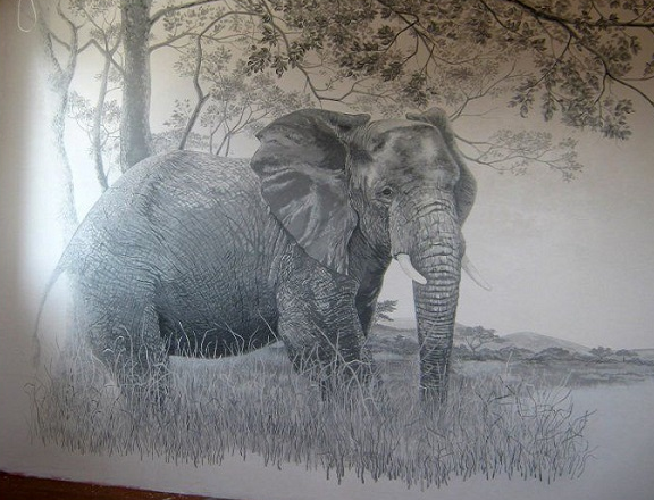

A real discovery in the matter of interior decoration was the emergence of hand painting and new environmentally friendly natural materials.

Relief and graphics

Applying graphic images to the walls of an apartment or house cannot be considered a truly new type of decor. Wall painting has been known for several thousand years. But with the advent of high-quality gypsum and decorative plasters it became possible to make the perfect background or base for drawing.

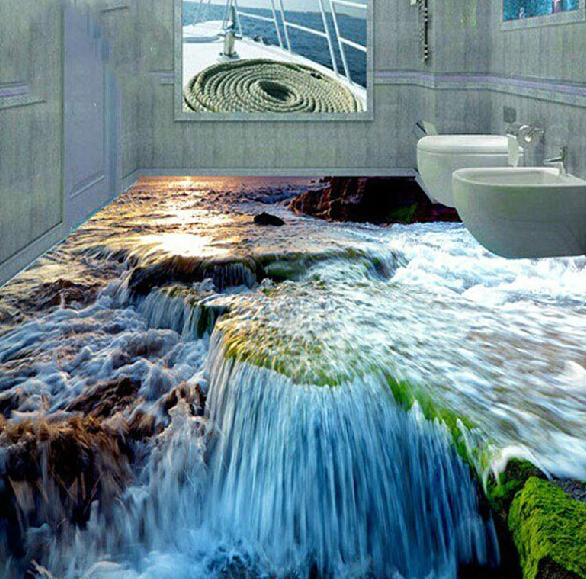

Hand painting instantly turned into an exclusive type of decoration, along with photo wallpaper and 3D decor.

Graphic images have become fashionable, especially in thematically oriented design of rooms using natural materials, specially made interior items and design.

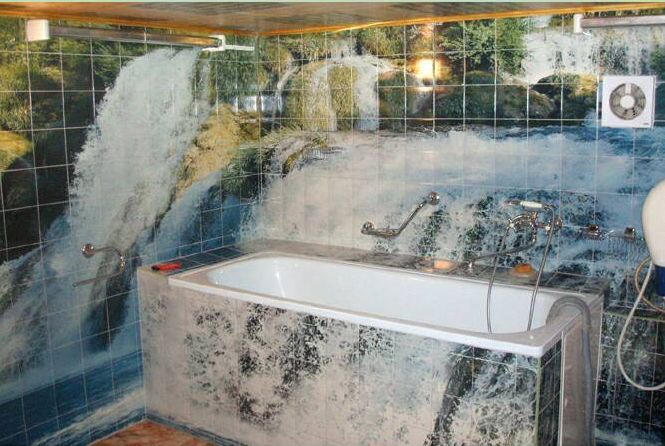

The new 3D photo wallpapers and tiles with a printed photo are considered very interesting. After sticking it on the walls of the room, the perception of space and perspective completely changes. A simple technique allows you to visually increase the spatial perception of small rooms, for example, a bathroom and a bedroom.

Natural materials

Traditionally, finishing from natural materials was limited to laying wooden parquet and gluing standard paper wallpaper using adhesive solutions based on modified cellulose. Modern interpretation environmentally friendly premises are increasingly forcing homeowners to abandon vinyl or non-woven wallpaper in favor of more exotic trellises made of cork, reed or woven bamboo fiber.

It is no secret that even new gypsum plaster mixtures contain surfactants, polymer plasticizers and dyes, so composite plaster materials based on finely ground silicon and lime are increasingly used to decorate the most important rooms in the house. The use of natural types of plaster is considered an absolute novelty, for example, Moroccan tadelakt - a waterproof coating without dyes and synthetic binders.

The most expensive type of finishing is the use of genuine leather and fabrics made of cotton, linen and jute.

New panel materials for finishing walls and ceilings

The advent of frame finishing of interior spaces has made it possible to solve the issue of repairing old rooms with crooked walls at a completely new level. Instead of throwing tens of kilograms of cement-sand mass, to level the surface, a relatively simple technology is used for laying flat, glass-like gypsum boards on a pre-assembled frame made of steel profiles. With the help of new technology, it turned out to be possible to level and cover walls even with extremely curvature of the surface.

Along with plasterboard for finishing work, MDF boards made from pressed cellulose fibers began to be used. The outer surface of this material is covered with a laminated layer that imitates wood, stone, or tile. The new, lightweight and flexible material can be used to decorate ceilings and walls, simulating cladding made from expensive types of wood or natural stone.

Relatively new technology finishing of ceilings is the use of heat-shrinkable polyvinyl chloride membranes. To decorate the ceiling surface, it is enough to stretch a thin polymer sheet onto a pre-mounted frame and heat the surface with a heat gun. As a result of shrinkage, the membrane is leveled to a mirror state, hiding defects and problem areas of the ceiling.

New floor materials

Among the new materials used for floor finishing, we can mention the appearance of self-leveling floors, the use of heavy-duty multi-layer linoleum and the creation of parquet flooring from tongue-and-groove boards.

The self-leveling floor is a mixture of mineral filler and water-soluble polymer resin. Using a low-viscosity but fast-hardening mixture, you can make a perfectly flat floor, which is subsequently covered with laminate or parquet boards. It is almost impossible to achieve such a surface quality by grinding or pouring concrete screed.

Commercial brands of linoleum of classes 33 and 34 can rightfully be considered a new finishing material. Unlike house brands of 21 and 23 classes, new material has an additional polyurethane coating, ensuring a service life of one and a half decades. Home linoleum will have to be replaced at least once every 5 years.

CEDAR façade board made of fiber cement and brick. A simple idea of zoning and a house from a simple boring brick “rectangular box” turns into a stylish, more expensive building, even just visually.

Popular options for exterior decoration of the facade of a house

Today, there are a lot of methods and all kinds of finishing materials for exterior finishing of facades. country houses. And the most popular among them are:

- vinyl siding,

- fiber cement siding,

- natural stone and clinker brick,

- facade decorative plaster.

Below we will discuss each of them in detail.

Vinyl siding

Vinyl (plastic) siding - facade panels made of high-quality polymers. The material is characterized by high mechanical strength, lightness and an impressive degree of resistance to negative atmospheric phenomena.

The photo shows “VOX” siding (Poland) (photo taken from open access on the Internet) Typical house

The photo shows the decoration of the facade of the house with fiber cement siding CEDARAL (feel the difference)

Structurally, vinyl siding consists of two-layer polyvinyl chloride (PVC) panels produced using double extrusion technology. The rigid inner layer occupies about 80% of the volume of the entire panel and serves to give the product the necessary strength and eliminate possible deformations. The thin outer layer is responsible for maintaining color brightness, fire resistance and protection from adverse external phenomena.

Vinyl siding panels are traditionally used for cost-saving purposes for cladding the walls of residential buildings and outbuildings. Externally, they imitate lining, ship timber, natural stone, etc. The main advantage of vinyl siding is the price. The material has a certain fragility, the thickness is only about 2-3 mm, for example, fiber cement siding has a thickness of 10 and 12 mm, fiber cement facade panels from 14 to 16 mm.

The advantages of vinyl siding are simple:

- low price;

- light weight;

- moisture resistance (plastic does not allow air to pass through, does not absorb water);

- waterproof (artificial material, does not decompose in nature);

- simple and easy installation;

- service life

- all availability (can be bought at any market).

But there are also disadvantages:

- Economy class. It looks “cheap” even on an expensive house structure. Does not visually increase the value of a house or building without increasing its capitalization. Indicates obvious savings. Your neighbor will definitely not envy you, and the investor will not appreciate the idea and will not add money for the façade solution;

- Mostly typical pastel colors, like everyone else;

- The material is not about design, a typical layout. Designers and architects don't like artificial materials.

- Poorly compatible with other materials in a single design solution. It's better to use it whole. Not best option for zoning or combination.

- The material does not burn, but melts slowly and can release substances harmful to health. (It’s no secret that one of the main problems of fire and risk to people’s health and sometimes life is smoke poisoning from plastics and chemicals. Without noticing the fire, people do not have time to leave the house or building and are poisoned by smoke.)

- Some types of plastics are electrified and attract dust;

- Brittle when exposed to low temperatures;

- Does not like impact loads or leaning heavy interior items (swings, benches), can be crushed under the load;

- Does not like heat - unlike fiber cement boards, it is not recommended for finishing facade areas where the surface is heated from a barbecue, tandoor, stove islands, etc.

- Low ergonomics, not a natural material.

- After use it pollutes environment, refers to non-degradable materials.

The choice is always up to the user. We only highlight the pros and cons of materials, and everyone makes the choice for themselves. The easiest way to do right choice- compare!

Plastic siding can be installed at any time, taking into account the physical characteristics of the material. It should be taken into account that plastic tends to expand when exposed to high temperatures and contract when exposed to low temperatures. Therefore, during winter installation a gap for expansion of at least 10-12 mm should be left. If the above rules are not followed, the facade will very quickly lose its attractiveness, moving in waves with the onset of heat or cracking during the first frost.

Fiber cement siding

On Russian market, a new generation of material has finally arrived for private housing construction, as well as any residential and commercial, social, cultural and administrative real estate; it has been widely used around the world for decades. And the climatic conditions in our country have long required a new, affordable solution in the form of boards for facades.

In this article we will focus on the application for finishing the facades of private houses, cottages, townhouses, verandas, bathhouses and terraces.

Fiber cement siding is excellent for exterior decoration of house facades, gazebos, terraces, bathhouses, garages and any buildings on the site or property. Belgian CEDRAL fiber siding panels uniquely combine the natural, warm aesthetics of natural wood with the physical characteristics of concrete. They do not require special care, are not afraid of exposure to precipitation and are characterized by impressive durability. Installed fiber cement siding is incredibly durable and easy to use. You don’t have to worry, it will crack from a minor impact like plastic or plaster.

How to upgrade a town house from “economy class” to “comfort +” and even “business class” category with minimal additional costs? This question is asked by every developer/builder. Simply add a façade solution with CEDRAL fiber cement boards. Effective, simple, affordable, fast.

Fiber cement siding Kedral combines perfectly with other natural finishing materials and can organically fit into any landscape, be it a fluffy green lawn with a gazebo and children's swings or a swimming pool under open air, gracefully bordered with stone tiles. And in order not to destroy the harmony of buildings, make a gazebo in the same style with a Kedral board; you will be surprised at how new your site with your house will look.

Advantages of fiber cement

Fiber cement is a very simple material. Fiber panels contain only 4 components: sand, cement, cellulose and water. During the process of forming and drying the panels, no chemicals are used; maturation of the material occurs in autoclaves under pressure and temperature. The finished panels are primed and coated in several layers with a super-resistant acrylate composition. Even after decades, the fiber cement facade will look fresh and new, will not fade, crack or become covered with efflorescence.

Add to list undoubted advantages fiber cement siding also includes:

- exceptional frost resistance; (already today objects with Kedral in all climatic zones)

- resistance to temperature changes over a wide range;

- resistance to moisture, sun, mold; (objects with KEDRAL in the forest thicket)

- absolute environmental friendliness;

- not susceptible to rotting;

- wide and stylish color range;

- easy installation all year round, does not require special training or long training;

- no need for special preparation of walls;

- affordable price, more than 300 points of sale throughout Russia from Arkhangelsk to Sochi, from Pskov to Vladivostok.

Unlike most materials for exterior finishing of facades of private houses, fiber cement siding can be installed year-round and used for cladding both new buildings and reconstructed old ones. Fiber cement boards do not become brittle in the cold and do not change their physical characteristics under the influence of different temperatures.

Natural stone

Natural and artificial stone a popular type of facade materials in finishing the facade of a private house. - But you should understand that cladding with natural or artificial stone is not suitable for every home. A simple, small house will simply look ridiculous with such a facade solution. The house, of course, must have a design and façade solution worked out by the architect, since it is quite difficult to create a successful layout on your own.

An example of a façade solution with a stone finish on different types house designs. An example of how important it is to choose the right material for finishing the facade of a house.

But zoning is quite accessible and does not sometimes require the expensive participation of a professional in exterior design.

But first, a little more information about the stone. A natural or artificial stone facade is not only durable if installed correctly. Important point, installation of stone can only be carried out at above-zero temperatures, since the work will involve wet processes. By combining several materials in a facade solution, you can truly create the facade of your dreams, taking as a basis the features you like from the whole variety of styles and trends.

We will not list the advantages of a façade made of natural stone; we will only note that one of the main ones is the opportunity to make a house very expensive both in appearance and in price, and of course, this good decision for houses with complex configurations and expensive and complex architecture.

Natural and artificial stone for the facade of a house

Another question is that today this option for exterior decoration of the walls of a house is the most expensive of all existing ones.

Most often, the following types of natural stone are used to decorate the facades of country houses:

- granite,

- quartzite,

- travertine.

As a slightly more affordable analogue of natural stone for external cladding, clinker bricks are used, produced from a special type of clay through complex technological processes. It consists of fireclay (fireclay), feldspar and special clay minerals. By mixing different clay masses, you can achieve a huge number of color nuances.

Facade solution for a Scandinavian-style house with fiber cement siding CEDARAL / CEDRAL

Installation of natural stone and clinker bricks involves wet work, which can only be carried out at positive temperatures. Additionally, you need to take into account a number of requirements, including:

- thorough pre-cleaning wall surfaces from ice and snow;

- introducing plasticizers into the masonry mixture to prevent it from freezing;

- use a freshly prepared solution for a maximum of half an hour;

- covering the masonry with a layer of waterproofing at night and some others.

Facade plaster

Exterior finishing of the facade of a house with plaster has a number of advantages, first of all, it is the ability to cover complex facades. Historically, plaster facades were most often used on buildings of pre-revolutionary architectural heritage, and it was on them that, even at the expense of reliability and strength, it was necessary to maintain the same appearance in the finishing. Otherwise, the owner of the building is free to decide which style of decoration is closer to him.

Plaster facades are still widely popular on the Russian market. But in Europe they are traditionally combined with other types of materials and this is already a tradition.

For example, like this:

Zoning in the decoration of the facade of the house, plaster and fiber cement siding CEDAR, looks expensive and stylish, especially in contrasting colors. You just need to pay special attention to the quality of the plaster, so the façade board will serve for at least 50 years without repair.

Fiber cement siding CEDAR and plaster. A simple example of 50/50 zoning. (feel the difference)

Plastering of facades is permitted in the temperature range +5…+25оС. If the rules for diluting the plaster solution are not followed or the preliminary preparation of the walls is carried out incorrectly, the plaster facade may crack after the first weather strength test.

What are the main advantages of the plastering system? Of course, this is the possibility of application to complex surfaces, excellent compatibility with other materials, variability and freedom in choosing color, texture and economy, in a certain sense of the word.

Disadvantages: limited temperature conditions for application and use, and the need for repair and renewal after several years of operation. For example, in areas with low temperatures, plaster facades are not the most popular type of facades, but in the south it is the opposite.

Fiber cement siding CEDAR and plaster, zoning and combining materials.

This analysis gives you the opportunity to consider different variations in home decoration for both private and commercial purposes. The best comparison is your own analysis based on the principle of “price - quality and labor costs”.

Analysis of the ease of installation of all the above materials for the exterior decoration of facades of private houses, the winners are materials that do not require special knowledge and effort, these certainly include facade boards and siding, including fiber cement siding, which is gaining popularity in our country by leaps and bounds.

More information about materials and the ability to compare them can be obtained from our dealers, see the Where to buy section. Samples different systems you can see, hold in your hands and compare live, which is extremely important and draw your own conclusions.