Storage water heaters, which are equipped in a large number of modern apartments and houses, significantly increase the comfort of living, ensuring stable operation of hot water supply systems. The reliability and safety of these devices completely depend on simple mechanisms that are included in the so-called “safety group”. Let's consider one of these devices, namely a safety valve for a boiler.

Purpose of the safety valve

When heated, the volume of water in the water heater tank increases by 2-3% depending on the difference between the initial and final temperatures. Even 2% for a 120-liter boiler is almost 2.5 liters of incompressible substance, which is any liquid. According to the laws of thermodynamics, in a closed system, as the temperature increases, the pressure also increases.

To be able to control the water temperature, boiler manufacturers install thermostats and thermostats in their products.

However, imagine what could happen if these elements fail. The water in the tank will boil, and the pressure inside the boiler will increase. An increase in pressure will provoke an even higher boiling point of the liquid, this process will proceed like an avalanche. At some point, the water heater tank will crack and some of the hot water will pour out, and cold water will begin to flow in its place. tap water. The entire volume of liquid will instantly boil, releasing large quantity steam, which will cause an explosion.

To ensure that the pressure does not exceed the permissible parameters, a safety valve is used that will release part of the liquid to the outside when the pressure inside the water heater critically increases.

In fact, the functions of water heater safety valves are not limited to protecting the device in critical situations, but have a broader purpose:

- prevent the return of heated water from the tank to the water supply;

- help smooth out surges in water pressure at the inlet to the boiler, thereby preventing the possibility of water hammer;

- dump excess liquid from the tank when temperature and pressure rise critically;

- provide the opportunity to drain water from the water heater during maintenance and repair work.

Valves currently produced have a variety of designs and configurations, including various shut-off valves, pressure gauges, etc. It is important that the installed device matches the parameters of the entire hot water supply system.

Design and principle of operation

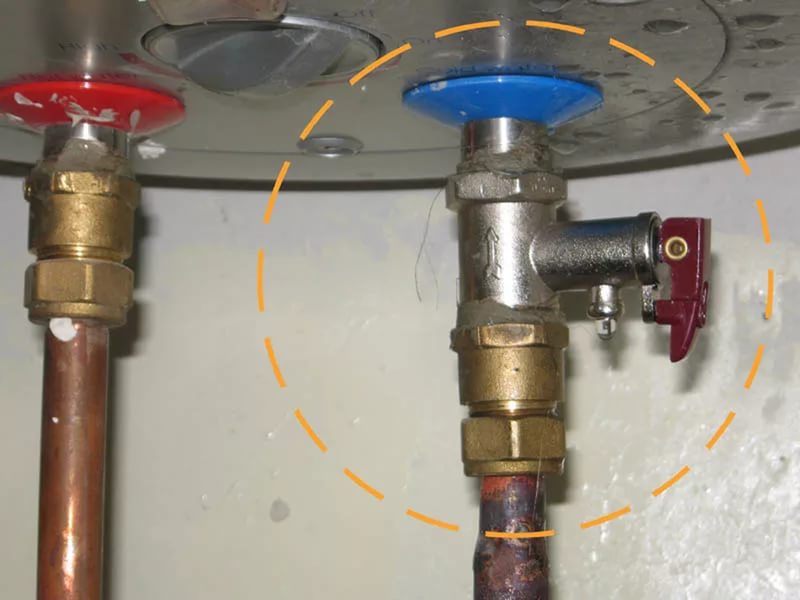

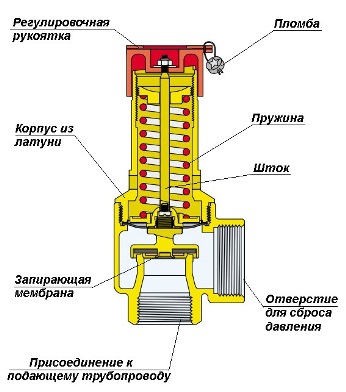

The boiler safety valve consists of two parts - the safety mechanism itself and check valve. Structurally, the device consists of two thin-walled cylinders of different sizes located perpendicular to each other with a common working cavity.

Inside the cylinder larger size a check valve is installed, consisting of a plate, a spring and a seat made in the device body. The threaded part on both sides of this part of the safety valve allows the device to be connected to the boiler inlet.

The smaller cylinder contains a similar locking device, the only difference being that the spring in its design initially has greater rigidity.

Most safety valves have the ability to adjust the opening pressure by changing the compression ratio of the spring.

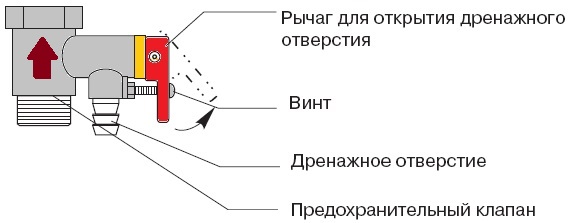

Behind the locking mechanism there is a drainage hole through which excess water is drained.

Often the design of the device provides an external lever, by pressing which you can move the plate away from the valve seat, thereby depressurizing the system. This is done to allow water to be drained from the tank without disconnecting the boiler from the pressure pipe.

The safety valve works as follows:

- When you open the tap on the inlet line, the check valve plate is pressed away from the seat and allows water to flow into the container. The liquid does not have access to the drainage hole, since the rigidity of the safety spring is set to a pressure significantly higher than the water pressure;

- When the boiler is completely filled, the pressure in the tank and the main line is equalized and the check valve closes. An increase in the temperature of the water in the container leads to an increase in its pressure on the check valve plate, pressing this element forcefully against the seat. Due to this, it becomes impossible to return heated water to the water supply system;

- If the pressure inside the boiler drops below the water supply (due to water withdrawal), the process of filling the container is repeated;

- If the thermostat fails, an uncontrolled increase in temperature will lead to a critical increase in pressure. This will compress the safety valve spring, opening the way for excess fluid to reach the drain hole.

The system could work without a shut-off valve. If the pressure inside the boiler increased, the excess water would simply be squeezed back into the supply line. However, in this case, you must be prepared to increase your electricity bills, because the boiler will have to heat not only the internal volume, but also an additional amount of water returning to the water supply. In addition, you need to be prepared for the appearance of hot water in “cold” taps. Some careless installers, who consider the safety valve to be an overkill, are convinced of this from their own experience.

Installation and operation rules

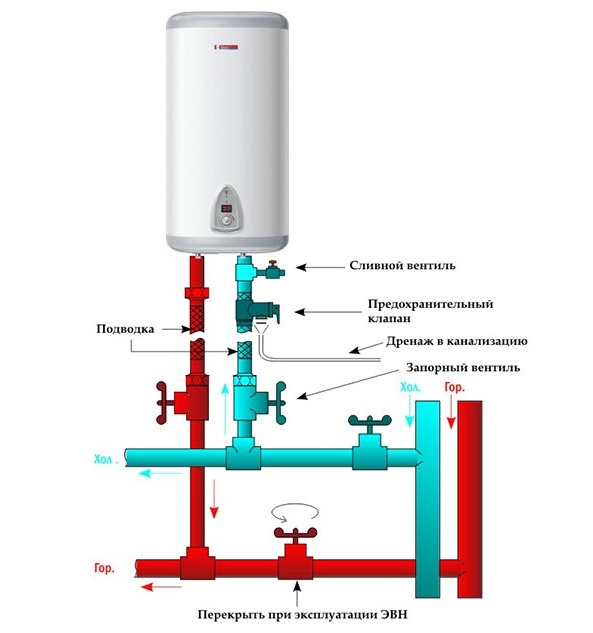

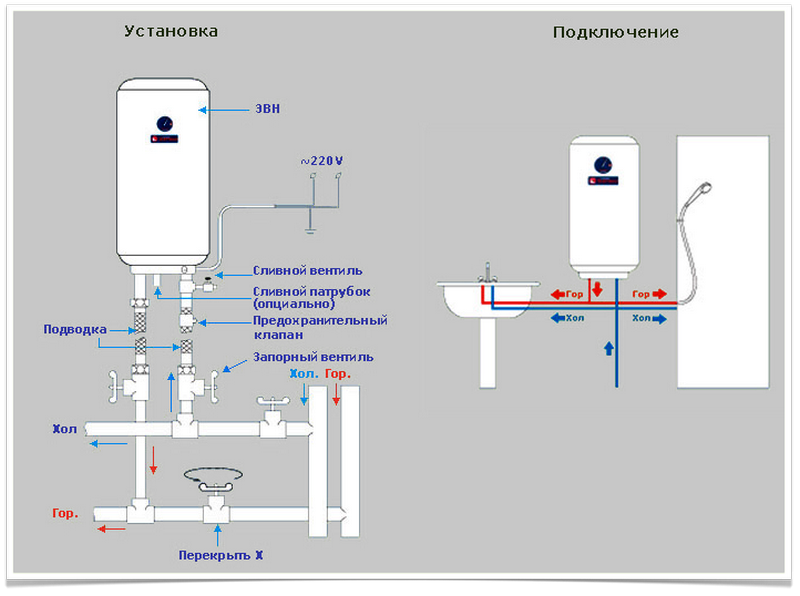

Typically the safety valve is installed directly on the boiler supply pipe. When installing it, you should orient the device along the arrow marked on its body. This mark indicates the direction of water flowing from the water supply.

The use of a transparent hose installed at the drain outlet will allow you to visually assess the serviceability of the valve. The end of the hose is discharged into the sewer or a suitable container.

When operating the boiler, ensure that the drainage hole of the safety valve is not blocked. To do this, you need to periodically check its serviceability by pressing the lever and draining a certain amount of water. This procedure is necessary to avoid a situation where the drainage becomes clogged with rust and dirt coming from tap water. Some devices have in their design not a lever, but a handle. In any case, you need to check the instructions to know how the forced opening mechanism of the valve works.

Do not change the factory settings of the spring stiffness in valves that can be adjusted in this way. This can lead to destruction of the water heater tank due to an unacceptable increase in pressure inside the device.

In some cases, water constantly oozes from the valve drain hole. This happens for two reasons - the valve is set incorrectly or the pressure in the pressure line is too high. In the first case, it is necessary to replace or adjust the device, and in the second, use a pressure reducing valve.

When installing a hot water supply system yourself, approach the selection of safety valve parameters responsibly, in accordance with the operating instructions for the water heater. If you are not confident in your abilities, then it is better to entrust this work to specialists.

Hot water- a useful and pleasant function in a person’s home. But there are cases when there is no such central communication, or the liquid flows barely warm. We have to buy a water heater. This apparatus combines near-boiling liquid and electricity. Therefore, measures must be taken to prevent danger.

The storage type heater tank is a hermetically sealed tank in which water is heated. During this process, steam is generated and pressure increases. That is why among the technical characteristics of the unit there is an indicator of maximum pressure. For household appliances it is usually 10 bar.

When in the evening all family members took a shower, bath and washed the dishes, the hot water was used up, and the tank was filled with cold liquid. While people sleep, the water heater heats the water, and the pressure inside the housing increases. All taps are closed, there is no return flow into the system. This means pressure accumulates in the boiler itself.

Having reached the set heating parameter, usually 60° - 65°, the thermostat should turn off the device. At the same time, the pressure in the water supply system is 2.7-3 bar, plus the steam from the water heated in the tank, for a total of about 4 bar in the heater housing. The situation is within normal limits.

Let's imagine that the sensor did not work. According to the laws of physics, the boiling point increases in proportion to pressure. For water at 10 bar, this parameter will be 180o C. The volume of liquid in the tank is about 80-100 liters, now all this mass has turned into steam. If the housing fails, an explosion will occur. A boiler safety valve can protect you in such a situation. This mechanism performs two functions:

- Prevents spontaneous drainage of liquid from the heater into the system when there is no water in the communications.

- Relieves excess pressure from the tank in automatic and manual modes.

Operating principle

Two valves are placed in one housing.

- The first, check valve, is located on the supply side cold water. As the tank empties, the pressure in the water supply becomes higher than in the tank and the inflow pressure pushes the seat away from the inlet. The path through which water enters the boiler is cleared. When the device is filled and the pressure in it and the pipes is equalized, the spring returns the seat to its place, thereby blocking the outlet from the boiler back to the water supply network.

- Second, safety valve for the boiler , during normal operation of the device is closed, and in the event of excess pressure, the jet from the unit acts on the valve, the calibrated spring is pressed out and the outlet channel opens, allowing the excess liquid to be discharged.

Installation

- The device is mounted directly on the inlet pipe of the water heater.

- When connecting, the direction of fluid movement must be observed. To do this, there is an arrow on the valve body, which should point towards the boiler.

- Some models may have an internal position stop. Such safety valve for boiler You can screw it all the way. If this option is not available, then when tightening the mechanism, you should make no more than 4 turns. Violation of this rule can lead to a narrowing of the safety channel.

- Having mounted the mechanism on the heater, look inside its body from the side where the cold water enters. The check valve seat should be visible. Try to press it lightly with a blunt object. If the installation is done correctly, the obstacle should move forward and return to its place after being released. If the saddle does not move, then the work was done incorrectly.

Attention! Cannot be replaced boiler safety valve a simple check valve. In this case, only the tank empty warning function will work. Excess pressure will not be released.

Examination

This procedure will take several hours to complete. During the entire test period, do not open hot water taps.

- After fully connecting the water heater and filling it with water, set the heating limit on the control panel to about 80 O .

- As the temperature rises, closer to the maximum, a trickle or drops of escaping liquid should appear from the fitting.

- If this does not happen, wait until the thermostat turns off the water heater.

- Depending on the characteristics of your model, increase the limit to the maximum possible.

- When the heating process is completed, liquid should drip. If there is no leakage, or the device is able to reach a level of more than 80 O It is recommended to have the valve checked by a workshop or replace it with a new safety mechanism.

- Place a hose onto the fitting of a working mechanism and secure it with a clamp. The second end must be taken to the sewer.

- If water begins to flow immediately after filling the tank, the device is defective, it must be replaced with a new mechanism.

If the safety valve is not installed on the boiler, operation is prohibited.

Selection

The basic rule that should be followed when choosing this device is that the response pressure of the mechanism corresponds to the characteristics of the heater. This parameter is indicated on the case or in accompanying documents. It is better not to buy models from which you can set action limits.

Please note that there is a forced fluid release lever. Inspect threaded connections, and make sure of the quality of their performance and the absence of thread defects.

The drain fitting should be placed so that it is convenient to put the hose on it.

Possible faults and solutions

- If, when the boiler is cold, water flows out of the emergency discharge hole, this means that, most likely, foreign elements have entered the valve. Open the drain channel completely using the lever and allow the liquid to flush thoroughly through the mechanism. When clean, transparent liquid flows through the hose, close the outlet with the lever. The leak must stop, otherwise the device must be replaced.

- Water is constantly flowing from the valve. This malfunction indicates that the spring pressing the seat has weakened. Since this part is calibrated, a new valve must be purchased. An extraneous cause of such a nuisance could be a significant increase in pressure in the cold water supply system, but this is unlikely and will be noticeable when using other plumbing fixtures. Unfortunately, there is another possibility for this defect - the absence or insufficient volume of the expansion tank in the boiler. The best option To solve the problem, you will need to replace the water heater with products from another manufacturer. If this solution is not possible, install an additional expansion tank at the outlet of the heater.

- If no liquid comes out of the fitting at all, and all the taps are working properly and there are no leaks in the hot water distribution system, wash the device as described in paragraph 1 or replace the mechanism.

Adjustment

Safety valve for boiler, adjustment

Safety valve for boiler, adjustment Having purchased a safety valve for a boiler, the adjustment of which is done manually, install the mechanism in the manner described above.

- Complete installation, connection and filling of the water heater.

- Turn on the device in a mode close to maximum in accordance with the manufacturer's instructions.

- Immediately after reaching the set temperature, turn the adjusting screw or knob, depending on the valve model, until water begins to flow out of the fitting.

- Drain some of the liquid from the tank. There will be space in the tank that will be filled with cold water. Accordingly, the temperature inside the heater will drop. Turn on the boiler's maximum operating mode again. Now water will flow from the discharge channel automatically. If this does not happen, loosen the spring until a thin stream appears. Check with another drain and reheat cycle.

- Set the operating mode to about 60 O . You should not constantly use higher temperatures unless absolutely necessary. This can cause increased wear on the heat exchanger.

Service

During use, depending on the intensity of hot water consumption, it is necessary to rinse safety valve for boiler from scale, rust fragments from pipes and other foreign matter in the water. To do this, you just need to sometimes open the emergency discharge channel of excess liquid using a lever.

This mechanism should not be used to empty the water heater. Particles settling at the bottom of the tank passing through the bleed spring will get stuck and interfere with its further normal operation.

By following all the rules for using the water heater and ensuring that the safety valve is working properly, you will confidently and safely use hot water.

To determine why exactly a safety valve for a water heater is needed, it is first worth remembering some rules from physics. Namely, everyone knows that when water starts to heat up, it increases in volume. If you heat it to 80 o C, then it will increase in volume by 2 - 3%, depending on what temperature the water was before heating.

Safety valve for boiler

Due to the fact that the container in which the water in the boiler is heated is completely sealed, strong heating increases the pressure inside it. If the pressure is not regulated, an explosion may eventually occur. In this case, a safety valve comes to the rescue by releasing a certain amount of pressure.

In other words, check valve:

- Prevents water from penetrating back into the water pipe;

- Helps normalize pressure inside the device;

- Provides the ability to drain water if required maintenance devices.

It is imperative to install it, just as it is important that it must be reliable.

Check valve for water heater

If you carefully examine the water discharge valve and what it is needed for, you will see that it is a whole system of valves, two in particular.

Namely:

- The first is responsible for relieving excess pressure. The safety valve is connected to a hole located on the side of the housing.

- The second valve is located below near the inlet. It is due to this that cold water does not flow out of the device if there is no pressure in the water supply.

Until there is less water inside the container than in the water supply, it presses the plate in the check valve and enters the container. As soon as the pressure becomes the same, the spring begins to press on the plate in the housing socket, which prevents the flow of additional liquid.

Subsequent actions to activate and block the valve are carried out as required.

Inside the boiler, the liquid gradually expands when heated. Once the permissible hot water pressure limit has been exceeded, the spring in the safety valve is compressed.

Next, the plate leaves the socket, opens the hole and drains the excess liquid. Once the optimal pressure level is reached, the plate returns to its original position.

Considering the device and how the mechanism works, we can conclude that a fuse is required for emergency pressure release, so as not to damage the equipment and not encounter an emergency.

Water pressure relief valve: how to choose

The drain valve for each type of boiler is individual, and it is included in the kit from the manufacturer.

The peculiarity of each valve is:

- Parameters;

- Connectors;

- Installation method and location.

If you need to replace the valve, you must first familiarize yourself with the technology of the work and, if necessary, it is better to contact a plumbing specialist. On average, the thread of pipes in apartment buildings and private buildings on water pipes is ½ inch, and therefore the product is selected according to the operating pressure.

The pressure value is indicated in the instructions for each water heater.

If the level of the protective device is designed for high pressure, then when installing the device there may be emergency up to the rupture of the tank, pipe and more. If the part is installed with less pressure than in the device, the valve will constantly leak.

When purchasing a boiler, you must definitely check the presence of a safety valve, and also make sure that it is in good working order and fits perfectly into the intended location.

The water heater data sheet contains information about which direction the valves should be turned when checking. When purchasing a valve separately, you need to consult with the seller so as not to endanger either yourself or the device. During operation of the water heater, it is necessary to check the valve and all equipment for malfunctions.

Safety valve adjustment

Installing a valve on a water heating tank requires careful work and maximum concentration. It is at the time of installation that a kind of adjustment is made to the valve, which has a spring mechanism. Regulation is carried out with a special handle, which does not need to be selected, because it is included in the kit. Namely, a part such as an adjusting cap is rotated, compressing a steel spring, and thus the load moves along the lever.

Important! If heating system functions stably and without interruption, and if the pressure is not exceeded, the relief or safety valve does not work for a long time.

This contributes to clogging of the valve and, accordingly, its contamination.

To avoid this you will need:

- Inspect the valve regularly;

- Turn on the valve and perform a special maneuver;

- A kind of cleansing.

This is how you can avoid damage to the product, because it may be needed at absolutely any moment, and if it malfunctions, serious consequences can occur, including breakdown of the product.

It is strictly not recommended to use on-off valves in the heating system. This is understandable, since when a critical pressure level is reached, the device automatically opens, which reduces the level as quickly as possible, just like the subsequent closing of the valve. All this causes water hammer, which leads to the rupture of the reservoir and the tank itself.

Installing a safety valve on a water heater

The operating principle of an indirect or safety valve is quite simple, because it contains two cylinders. The large cylinder is a so-called check valve, which has a special flap or poppet valve. It is driven by a small spring.

Both ends of the cylinder have special threaded parts, through which the product is connected to the required connectors.

The small cylinder is installed vertically relative to the large one. The ends are plugged with special plugs and it is equipped with a drainage tube as well as a built-in small valve. There are certain types of valves installed on the boiler.

They may differ in key parameters, for example, in the installation method:

- Irretrievably constipated.

- Adopted.

- Steel.

- Ball.

Depending on the principle of operation of the water heater, there are various types check valve: direct, indirect, two-position and proportional.

There are also types of check valves that have different heights of lifting the constipation:

- Full lift.

- Mid-rise.

- Low lift.

The purchase of a safety valve should be carried out in specialized stores and preferably taking the old part with you. In the absence of such a detail, you should rely on technical specifications water heater models. It is worth noting that by leaving the work of installing or servicing fuses to a technician, you can thereby protect yourself from serious consequences.

In particular:

- Breakdowns;

- Pipe rupture;

- Tank explosion.

Specialists not only use the necessary equipment, but also provide a guarantee for the actions performed. In other words, by entrusting the work to a specialist, you don’t have to worry about the fact that the service life of the equipment may be shortened or the valve will not perform its intended task.

Why do you need a safety valve (video)

It is strictly forbidden to start the boiler without proper installation of the valves and without first checking the quality of the installation, which is carried out through a test run of the equipment. If there are no leaks or air leaks, the device can be operated without fear. The blast defense mechanism must be in good working order.

Attention, TODAY only!

Buying your first electric boiler is a significant event. It is impossible to forget it, if only because for the first time you have to figure out why the water heater needs a power cord, as well as how to connect and install the entire system.

Subsequently, as a rule, no questions arise, so when replacing the boiler with a new one, reading the accompanying instructions is often skipped. Today we will talk about why a safety valve for a water heater is needed and what will happen if you “forget” to install it.

Laws of physics

Every person knows from childhood that when heated, objects expand, increasing in volume. The value depends on the material of the object, temperature and conditions environment- these are the laws of physics. And water is no exception. If there is an increase in volume in a sealed enclosed space, then mechanical damage to the boundaries is quite possible - they will simply be torn apart. The safety valve for the water heater, which is necessarily included in the boiler installation kit, serves to protect the walls of the tank from destruction.

If it is missing, it must be purchased and installed separately. To understand the operating principle of a water heater safety valve, let's mentally assemble a model of the tank and connect it to the system.

Experiment

Two pipes are connected to the boiler: the supply of cold water and the return of already heated water. While the taps on the outgoing line are closed, the volume of the tank will be filled with cold water, which will begin to be heated by the heating element to the set temperature. As soon as you open the tap, hot liquid rushes out of the tank, squeezed out by portions of cold liquid coming from the system. However, there are several points that do not allow the boiler to be operated with this switch on. Firstly, since the entire mass of cold water (in the tank and pipe) is not divided by anything, the heating element will constantly work, trying to heat the entire available volume. Secondly, if for some reason the water disappears in the supply pipe or the pressure drops significantly (not uncommon in domestic systems), then the stored and heated liquid from the tank will partially flow back by gravity into the supply pipeline. To prevent this from happening, a check valve is installed on the connection pipe. The spring-loaded plate allows water to flow in only one direction, mechanically separating the two media - the simplest, but incredible effective solution. Why do you need a safety valve for a water heater? Let’s mentally complicate the task by adding to the design the usual one installed on the feed. In this case, heating will occur without losses, and the disappearance of water in the supply pipeline does not threaten anything.  But what happens if the heating value is set not to 20-30 degrees, but to 60-80, as often happens? In accordance with the well-known law of physics, the water will begin to expand, and since all the taps are closed, the internal pressure will increase. If the walls of the tank are of poor quality, they will be locally damaged (burst). And if the tank material is chosen correctly, then the following happens: the pressure and temperature increase, but the water does not boil, since at high pressure the point moves. As a result, it turns out that the boiler may well contain water with a temperature of over 100 degrees. But then someone opens the water tap. The pressure drops sharply, returns to the usual 100 degrees, an avalanche-like release of steam occurs, which sharply increases the pressure and the tank bursts. If you manage to avoid injury, it can be considered lucky.

But what happens if the heating value is set not to 20-30 degrees, but to 60-80, as often happens? In accordance with the well-known law of physics, the water will begin to expand, and since all the taps are closed, the internal pressure will increase. If the walls of the tank are of poor quality, they will be locally damaged (burst). And if the tank material is chosen correctly, then the following happens: the pressure and temperature increase, but the water does not boil, since at high pressure the point moves. As a result, it turns out that the boiler may well contain water with a temperature of over 100 degrees. But then someone opens the water tap. The pressure drops sharply, returns to the usual 100 degrees, an avalanche-like release of steam occurs, which sharply increases the pressure and the tank bursts. If you manage to avoid injury, it can be considered lucky.

Safety valve for water heater "Ariston"

To prevent such accidents, they are designed in such a way that when a certain value of internal pressure is exceeded, part of the water is automatically discharged (usually a few milliliters). The layout of these elements is the same, so there is no difference whether they are installed on an Ariston, Termex, or other boiler. Inside there are two spring-loaded plates: one of them functions as a simple check valve in the supply, and the other holds water in the tank until until the pressure exceeds a certain limit.

The operation of water heating equipment is directly related to changes in the pressure level in the system. Its adjustment is necessary for the safe operation of the electric storage boiler. Modern water heaters are equipped automatic protection from high pressure in the tank. However, a water heater safety valve is essential to ensure safe operation.

Purpose

The storage boiler is based on maintaining a certain volume of hot water, which is automatically replenished when it is used. In the absence of outflow from the tank, the electric heating element continues to operate. Hot water expands and its force inside the tank increases.

Water is a substance that is practically incompressible. When the temperature rises to 80⁰ C, it increases in volume by 2-3%. Excessive pressure inside the tank can damage it and create an emergency situation.

To relieve excess water pressure it is used protective device safety – safety valve. Installed on the pipe for introducing cold water into the boiler. Excess volume is removed through it. When the pressure inside the tank normalizes, the protective mechanism closes and the outflow of excess volume stops.

Design features

Safety valve design for water heater:

- Frame

- Reset fitting

- Release lever

- Two poppet valves with opposite direction of operation

- Safety valve spring

- Check valve spring

Structurally, the safety valve looks like two cylinders placed perpendicular to each other. The large cylinder has a threaded part at the ends for mounting to the water heater and water pipe. There is a check valve inside the cylinder, pressed by a spring.

The cylinder perpendicular to the large one is smaller in diameter. One side of it enters the cavity of a large cylinder. On the other side there is a plug or handle for forced pressure release. In the cavity of the small cylinder there is a drainage pipe with a poppet valve in the opposite direction of operation.

Structurally, it looks like two cylinders placed perpendicular to each other. The large cylinder has a threaded part at the ends for mounting to the boiler and water pipe. There is a check valve inside the cylinder, pressed by a spring.

The cylinder perpendicular to the large one is smaller in diameter. On one side it goes inside the large one, on the other side there is a plug or handle for forced release of the water pressure. Inside the cavity of the small cylinder there is a drainage pipe with a disc-shaped design in the opposite direction of operation.

Operating principle

The safety safety valve is a direct-acting device. When the tank of the water heating device is filled, the force of the liquid presses the poppet valve, allowing the tank to be filled.

After filling the tank, the water pressure inside will increase; under its influence, the check valve of the large cylinder will close, preventing the outflow back through the water supply system. As the liquid inside the reservoir decreases, its force gradually decreases. The check valve is pressed out, resuming filling of the tank.

Increasing the temperature increases the pressure level. Under its influence, above the permissible value, the disc-shaped structure of a small cylinder is activated, a drainage hole opens, and the excess volume is discharged out. The pressure inside the system is equalized, the reverse returns to its original position.

Functions

- Prevents the reverse outflow of liquid from the storage tank.

- Removes excess volume from the water heating tank to stabilize internal pressure.

- Eliminates pressure drops within the central water supply system.

- The positive release lever can be used to drain during maintenance.

- Extends the service life of electric heating elements and water heating equipment.

- Saves energy by preventing the heating element from running idle.

- Protects against emergency situations of overheating and explosion of the storage boiler.

Species

They differ in the following points:

- Release lever. It is needed to check the proper operation of the mechanism; it is advisable to check it once a month. By lifting the lever flag, you can empty the storage tank. It is important to pay attention to the design of the checkbox. Some models are manufactured with a small screw attached to the lever to prevent accidental opening and emptying of the tank.

- Arrow on the body, designation of the nominal operating pressure of the safety mechanism. It is recommended to purchase devices with these designations on the body in order to choose the best option.

- Drain fitting. Produced different shapes. It is preferable to have an oblong, stepped shape to make it easier to put on the outlet hose and crimp it with a clamp if necessary.

- Without release lever. When purchasing this modification, you should pay attention to the presence of a threaded cap. It will allow for further maintenance (removing blockages, scale, dirt). This is the preferred option.

- For large-capacity boilers (from 60 liters), other models with additional mechanisms are available: ball valve, pressure gauge, standard fitting thread. These models are more diverse in species composition. You can choose the option you like best. Their cost increases significantly compared to standard analogues, and can even reach the price level of cheap heating equipment.

Safety or reverse?

Installing the reverse instead of the safety one can lead to unpleasant, life-threatening consequences.

The reverse will prevent the flow of hot water from the boiler tank through the plumbing system. The liquid warms up to its maximum temperature, its effect inside the tank increases. If the thermostat fails, the temperature will continue to rise along with the pressure, increasing the boiling point.

When dumping excess volume through water tap The boiling point will return to 100⁰ C, but the temperature in the tank will still be significantly higher. Instant boiling of the remaining liquid and the release of a large amount of steam will lead to a strong explosion that will damage water heating equipment and the walls of the room.

If the safety valve is not installed

Without the safety mechanism installed, the water heater will not operate properly.

With a constant volume inside the storage tank, an increase in temperature will cause an increase in the force of impact. Having reached a value that exceeds the pressure level of the central water supply network, it will begin to push hot liquid through the water supply. If you do not open the hot water tap, the normal pressure inside the tank will be regulated by releasing it into the cold water pipe. Water heating equipment will waste electricity.

If the pressure in the water supply system decreases (reduction of load at water pumping stations at night, accident, repair work), the supply pipe will be empty. Hot water from the water heater storage tank will flow out through the empty pipe. For models without automatic control of the electric heater (or with malfunctioning automation), the heating element will heat idle, which will lead to its burnout.

- You should choose a spring mechanism. It is reliable and has good resistance.

- It is recommended to take into account the features of the water supply system and, if necessary, install a reducer to regulate the pressure of water supplied from the central water supply network.

- Need to take into account throughput defense mechanism.

- It is necessary to correlate the maximum permissible pressure level in the water heating system with the operating pressure of the safety mechanism. If the pressure of the latter is low, water will constantly flow from it. At high – it will not operate when the water pressure rises above the permissible level.

Installation

- The water heater must be disconnected from electrical network, empty the storage container.

- Install the valve mechanism on the cold water pipe. Connect one end to the pipe, install the other into the boiler. It is necessary to monitor the direction of water movement (indicated by an arrow on the body).

- If necessary, install a water reducer upstream of the valve structure to stabilize the water pressure from the central water supply system.

- Connect the drainage outlet of the mechanism with a flexible hose to the sewer system. To monitor proper operation, it is recommended to connect a transparent hose.

- When concealed installation behind water heating equipment is prohibited:

— install locking devices between the boiler and the safety valve mechanism;

- make the distance from it to the boiler more than two meters.

How to check if it's working properly?

You can check the serviceability by turning on the water heater (do not open the hot water tap) and wait until the water is completely heated to the maximum possible temperature. After a while, excess water should drip from the safety mechanism.

The valve will not work if:

- the hot water tap is faulty (pressure will be released through it);

- the thermostat is set to 30-40⁰ C (the water will not warm up to such an extent that the pressure inside the tank reaches the permissible level);

- the operating pressure of the safety valve device is high and does not correspond to the productive capacity of the water heating equipment (the maximum permissible pressure in the storage tank will not be sufficient for the safety valve mechanism to operate. It may have dangerous consequences).

Water from the valve device must be drained periodically. If this does not happen and all of the above cases are excluded, the fuse itself is faulty. It needs to be replaced with a new one, having first checked its performance.

A safety mechanism must be installed on water heating equipment to ensure long, uninterrupted, safe operation of the device. You should choose the option that is most suitable in terms of all design and functional parameters, otherwise its operation will be ineffective and even dangerous. In this case, it is necessary to periodically check its serviceability, approximately once a month. If a malfunction is detected, the inoperative valve must be replaced with a new one.

It is very dangerous to improve it independently, replacing it with a check valve mechanism. This will lead to unpleasant consequences, due to which it is likely that you will have to replace the purchased water heater with a new one.