Large diameter steel pipes are products with an external volume of 530 mm or more. The leading areas of use of these types are: oil pipelines, gas networks, water pipelines, heating networks and drain lines. They are also in great demand during construction activities.

They are also used in the field of mechanical engineering and in the manufacture of metal structures, in ventilation and other pipelines. And everywhere the dimensional products have proven themselves to be the best.

Almost all products in this product line are of high quality and reasonable prices. Leading domestic manufacturing plants are located in Chelyabinsk, Almetyevsk, Khartsyzsk, Izhorsk.

For large diameter steel options. This is done using special materials. For water supply and oil and gas pipelines this is a necessity.

This protection helps reduce costs and heat loss in production; it must be selected and applied to products correctly. Otherwise, the pipeline will not be able to function without accidents, and operating costs will increase.

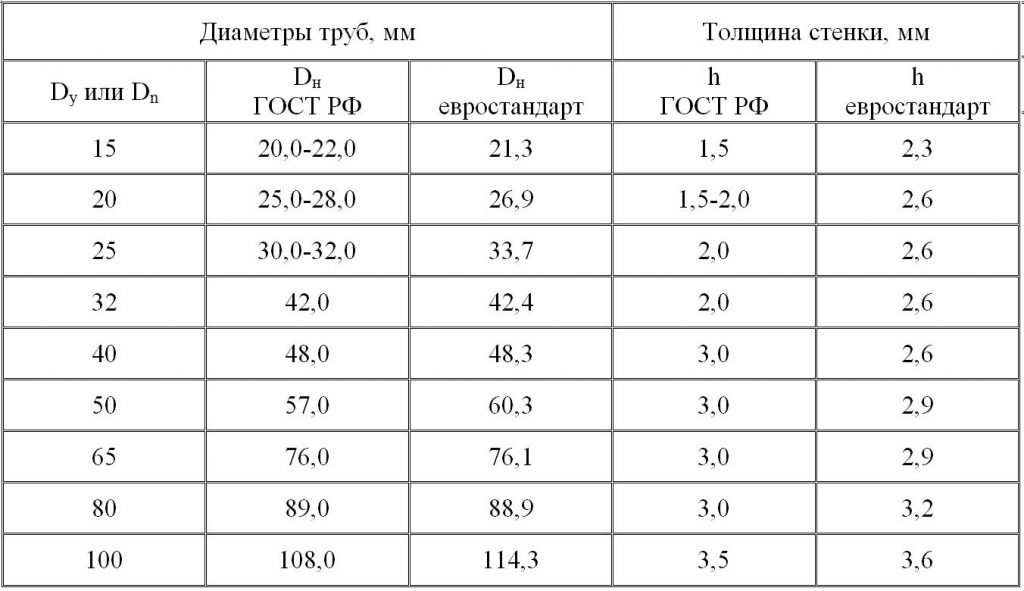

Outer and inner diameter. They may be as follows.

- Conditional. Displays the nominal internal dimensions.

- Nominal. This is the actual size of the dimensions.

- Outer. .

- Internal. This value is very important when choosing connecting elements for large volume pipes.

At the same time, the indicator of wall thickness for pipe-rolling materials of this type becomes no less important.

Certain fixed values for the outer diameter of these products are also known. They make it possible to select the required dimensions, taking into account the preliminary tasks of the structure being designed.

In reality, the outer diameter plays a significant role in certain situations. For example, when constructing units for drainage in premises, because in this situation fasteners are selected taking into account the values of the outer diameter of the main elements.

Volume Standards

Standard diameters of steel pipes are provided in GOST 10704-91. All standard products are conventionally divided into the following.

- Large size pipes. This includes dimensions exceeding 508 mm. They are mainly installed by gas and oil networks.

- Types of medium volume. These product lines range from 114 to 508 mm in diameter. Their task is to provide the city water supply pipeline and maintain industrial pipelines that collect crude oil.

- Products with small diameter (up to 114 mm). They are installed in pipelines of end-use networks.

Video

You can find the required sizes in the table provided (all designations are shown in):

| Large | Average | Small |

| 1420 | 530 | 108 |

| 1220 | 478 | 102 |

| 1120 | 426 | 95 |

| 1020 | 406 | 89 |

| 920 | 377 | 88 |

| 820 | 355 | 76 |

| 720 | 325 | 73 |

| 630 | 273 | 70 |

| 530 | 244 | 63 |

| – | 219 | 60 |

| – | 193 | 57 |

| – | 180 | 54 |

| – | 177 | 53 |

| – | 168 | 51 |

| – | 159 | 48 |

| – | 152 | 45 |

| – | 140 | 44 |

| – | 133 | 42 |

| – | 127 | 40 |

| – | 114 | 38 |

| – | – | 36 |

| – | – | 35 |

| – | – | 33 |

| – | – | 32 |

| – | – | 30 |

| – | – | 28 |

| – | – | 27 |

| – | – | 26 |

| – | – | 25 |

| – | – | 24 |

| – | – | 23 |

| – | – | 22 |

| – | – | 21 |

| – | – | 20 |

| – | – | 19 |

| – | – | 18 |

| 16 | ||

| 15 | ||

| 14 | ||

| 13 | ||

| 12 | ||

| 10,2 | ||

| 10 |

What dimensions does it have? steel pipe table shows standard sizes. Tables are convenient to use when determining exact dimensions. But, the range of steel is often shown in inches. This measurement is widely used in many countries around the world.

![]()

GOST

Large-diameter steel pipes are in great demand in the field of metallurgical products. They are installed during the construction of ventilation, water and steam pipelines, gas and oil pipelines. Large diameter pipes meet the highest quality standards.

They are distinguished by reliability and a long period of use. It is for these reasons that they are produced for systems where reliability and long term use are the primary requirements.

They are distinguished by reliability and a long period of use. It is for these reasons that they are produced for systems where reliability and long term use are the primary requirements.

Dimensions and all permissible deviations must comply GOST 10704. When producing pipes of large dimensions, only one seam is made. According to regulatory requirements First, a seam is made on the outside, and then on the inside.

Assortment

The range of large-diameter steel pipes is determined by GOST standards, which differ in production methods. On the secondary market you can find products with volumes from 159 to 1420 mm.

Video

This range for large-volume pipes starts from 53 cm. At the same time, straight-seam (l/w) options larger than 1420 mm are not provided for by GOST, but there are straight-seam options of this volume. Straight-seam products are produced from 8 mm, and types with a spiral seam are produced with a volume of at least 159 mm. Such variations in overall dimensions are based on the release technology.

According to the assortment, each product has an individual spectrum wall thickness. The larger the volume of the steel billet, the greater the minimum thickness of its walls. It should be added that the size of the walls has a direct impact on the weight of the product and its cost.

GOST does not set strict standards for the length of pipes. In addition to the requirements for geometric parameters, the entire range of pipes must meet specific technical standards. They determine the types of seams, steel, markings and complexity of testing events that the pipe must undergo.

Electric welded pipes

Electric-welded steel pipes of large diameter are produced from strips or sheet material through molding and electric welding. When welding the transverse axis, a straight seam emerges. This is where the name for this type of product comes from – straight-seam.

To increase the anti-corrosion capabilities, the products are treated with special compounds. And the raw material for the manufacture of such products is carbon and low-alloy steel.

The main areas of use of these steel products are pipelines, metal structures and mechanical engineering. Electric welded pipes large diameters are used in gas and oil networks, water supply and heating mains.

Straight-seam electric welded products produced by welding are widely used in laying highways and constructing metal structures. Depending on the type of steel, electric welded options receive this marking.

- SP. These are straight-seam electric-welded options made of mild steel.

- PS. These are electric-welded straight-seam products made of semi-quiet steel.

- KP. These are electric welded products made from boiling steel.

GOST standards for large-diameter seamless steel pipes are becoming the most popular when laying systems for various purposes. The thickness of the walls of these pipe-rolling materials reaches 5 cm. They also have a high permeability indicator, which provides for an internal pressure of up to 12.5 MPa.

They are made from the following types of steel:

- Structural unalloyed (S185, S195T, etc.).

- Half calm and calm (VSTZ).

- Carbon half calm and calm ST3, ST4.

- A low-alloy type permitted by the requirements with a carbon composition of no more than 0.48.

Video

Typically, the length of the assortment of large pipe products is impressive, reaching fourteen meters. For seamless types, a significant variation in length is achieved. According to GOST they are:

- Measured. The largest deviation in this case may be no more than 1.5 cm.

- Multiple measured.

- Limited type within the limits of dimensional extent. The largest deviation in this case is no more than 50 cm.

- Unmeasured. The length indicator in this case is specified by the client.

Manufacturing

The production of large diameter steel pipes occurs as follows. The quality level of these pipe-rolling materials is controlled by quality control testing; they are checked for stretching, bending, compression, and are subjected to water hammer.

The labeling information provided to clients is as follows.

- Name of the enterprise - manufacturer.

- Product name.

- Real specifications.

- Production date.

- Batch number.

- Conclusion on how well this product meets the requirements of the specifications and working documentation.

Many domestic companies that produce large-sized rolled steel products are independent cells of the production sector. They have proven themselves to be reliable partners and supply products of the highest quality and at competitive prices.

Video

Their products are characterized by a high level of operational and technical capabilities, and are almost not subject to deformation changes and temperature changes.

The entire line of products is manufactured in strict compliance with regulatory requirements and has received all the necessary certificates. This level of quality opens up great possibilities for the consumer to use them.

Speaking about the production of this line of goods, one cannot fail to mention their transportation. The whole point is that their transportation must be carried out in strict accordance with accepted safety standards.

Such transportation is carried out on low-frame long vehicles. These cars are equipped with special clamps that make it possible to secure the load.

Steel pipes standard length and small volumes can be bundled, but large-sized assortments must be laid and fixed separately.

For such transportation, it is allowed to use movable carts that are combined with tractors with a hitch, and it must have its own tagging system.

Video

IMPORTANT! Vehicles traveling in a convoy transporting large-sized rolled steel products must be accompanied by a truck crane. It may be needed for emergency lifting of accidentally dropped goods.

(2 ratings, average: 5,00 out of 5)

Discussion is closed.

The diameters of steel pipes, the table of which will undoubtedly be useful during construction of any scale, are the main parameter that is as important for marking as the wall thickness.

If we talk about pipes not made from steel, then along with the wall thickness and dimensions, the material from which they are made must also be taken into account. The diameters of pipes, depending on their purpose, are clearly regulated relevant technical specifications or state standards.

It is also important to take into account the fact that the determining parameter is the diameter exclusively for cylindrical standard pipes. For profile pipes, due to their special shape, the width and height of the cross section are specified.

When marking products of this category, the value of the external (outer) diameter is taken. But the internal diameter, which determines throughput pipes, can be found by subtracting double the wall thickness from the outer diameter: D (inner) = D (outer) - 2t (where t is the wall thickness)

Diameters of combined and polymer pipes

IN mandatory must be consistent with GOST R 52134-2003.

The dimensions of pipes made from polyethylene can be found in GOST 18599-2001. And the different diameters of metal-plastic (multilayer) pipes are determined by GOST R 53630-2009.

Polymer pipes

Very rarely, in some cases that are not provided for by currently existing state standards, the diameters of combined and polymer pipes may have different sizes.

Diameters of metal water pipes

Steel pipe diameters

The dimensions of steel pipes, the table of which is given below, are defined in GOST 10704-91. Standard products are divided into three categories:

- large diameter (more than 508 mm). Used in the construction of main gas and oil pipelines;

- medium diameter (114-530 mm). Their main function is to provide city water supply systems and maintain field crude oil collection systems;

- small diameter (no more than 114 mm). Installed in water supply systems at end points of consumption.

Steel pipes

You can find the required dimensions in the following table:

Cast iron pipes

In accordance with GOST 6942-98, the diameter of cast iron pipes can be 150, 100 and 50 mm. It should also be taken into account that in this case the diameter is conditional passage D y, equal to the internal diameter of the cast iron pipe. The size of the connecting parts also depends on it.

Aluminum and copper pipe sizes

In most cases, the outer diameter of copper pipes (used for domestic purposes) is measured in inches.. Find full row diameters (in mm) can be found in GOST 617-90.

Copper pipes

And the size range includes the following values (in mm): 132; 130; 127; 125; 120; 113; 110; 105; 100; 95; 93; 92; 90; 83; 70; 58; 55; 42; 41; 39; 38; 36; 34; 32; 30; 29; 28; 26; 25; 24; 22; 20; 18; 16; 13; 12; 8.

Water supply steel pipes are still successfully used to create water supply networks. To find out exactly in what situations it can be used, you will have to understand in detail all the pros and cons of its operation.

Since the time they began to use pressure-type water pipes and pumps to increase water pressure in pipelines, water mains began to be installed from steel. It would seem that there is an abundance of others modern materials could have displaced these products from the ranks of popular ones, but this did not happen.

Rolled metal pipes modern market takes up a significant share of sales. If they are very popular, it means they have certain characteristics that set them apart from similar products.

A steel water main is appropriate where there is a risk of mechanical stress on the pipeline. If it takes place underground or on the street, then undoubtedly the most best material for her it is steel. This conclusion is based on strength capabilities, because this material has its drawbacks in other areas.

Also for pipelines transporting water under high pressure loads, best option than steel, you simply cannot find it.

For example, after the booster pump, the line is under the following adverse influences:

- Vibration.

- Significant pressure surges when the replenishment is turned on and off.

It is incorrect to call these products the cheapest, although they are among the least expensive. Also a big plus is that it is easy to select fittings for such highways. While similar plastic parts are sometimes not easy to buy, steel fittings have large assortment.

Due to the small coefficient of thermal expansion, these pipes can be installed under plaster. The use of other materials in this situation is fraught with the occurrence of cracks when heated.

See also everything about: galvanized and non-galvanized, with threads, etc.

Steel water pipelines have the following characteristics. Some positive aspects have already been partially discussed above, but not everything is so rosy with this pipe assortment.

He also has negative characteristics:

- Corrosive formations. Unfortunately, steel is susceptible to this effect. And the water supply system feels this with particular acuteness. In it, moisture is constantly combined with atmospheric oxygen. Such a combination is simply destructive for steel.

- Decrease in lumen over time. Such a highway tends to become overgrown over time. Her clearance can catastrophically decrease in just a couple of years.

- Labor-intensive installation and dismantling. Speaking about a steel pipeline, we must immediately make a reservation that assembling it is more difficult than tightening several nuts on fittings of a metal-plastic structure, or welding polypropylene pieces with a small welder. Compound steel water pipe will require the participation of a professional welder.

- Impressive weight. This characteristic feature steel water pipes rolling materials significantly complicates transportation and installation.

IMPORTANT! Steel networks can be protected from such a significant drawback as corrosion by priming and painting.

Types of steel pipes for water supply are provided below. Thus, they are divided into:

Types of steel pipes for water supply are provided below. Thus, they are divided into:

- Galvanized. This category consists of products that have been finished with zinc on both sides. This protective layer greatly increases the anti-corrosion capabilities of the products.

- Profile. They are made from carbon steel. These options are widely used to create buildings with increased stability and metal frames.

- Seamless. Hot-deformed products are a line of rolled pipe products that do not have a spiral or longitudinal welding fastening (seam). The production technology in this case consists of finishing hot-deformed types under the influence of high temperature.

- Electric welded. For production in this case, low-gel and carbon steel are used. Most often in the form of a sheet or strip. Electric welded products are widely used for laying heating networks and in the construction of other networks and structures.

- Water and gas pressure. A very significant point for them is the ratio of the internal and external diameter, which depends on the thickness of the walls. Based on the wall thickness, this type of pipe rolling range is conventionally classified into: reinforced, standard and lightweight.

Galvanized steel water pipe deserves special attention. This coating significantly extends the service life and reliability of the highway. These products are universal and widely used in everyday life and in industry.

Such a fact as increased protection against corrosion by galvanizing allows them to be installed not only in the supply water system. They are recommended for installation in heating.

Compliance with GOST requirements becomes a firm guarantee of high anti-corrosion properties, reliability and durability.

GOST 3262-75

Manufactured in accordance with GOST 3262-75. In accordance with this regulatory document determine the nominal bore and wall thickness of a given product.

It can be equipped with rolled or cylindrical threads. They can also be without thread. Rolled pipe assortment, manufactured in accordance with GOST 3262-75, is installed not only in the water supply network, but also in the gas supply network.

In addition, they have found their application in the manufacture various designs on sports grounds. These are horizontal bars, support structures and much more.

Video

Depending on the wall thickness, there are light, ordinary and reinforced options. Their wall parameters are also regulated by GOST 3262-75.

Duration of operation

The service life of steel water pipes is very impressive. For these reasons, they have become the undisputed leader for highways for various purposes. In the heating system it is better to use pipes made of black steel, and in the water supply it is more appropriate to install galvanized types.

When using these products in metal communication systems, it is necessary to pay attention to the features of their production. This is reflected in the duration of use.

Rolled pipes can be electric welded and can be installed in water supply, heating and gas supply networks. Their problem is that their throughput volumes are smaller than those of similar copper or polymer pipelines.

The reason for this is the surface inside steel plumbing systems, it is rough and creates eddy currents in the distilled liquid. Thus, the flow of the medium is hampered.

A distinctive feature of these pipes is that their service life is not affected by hydraulic load. High loads of this kind do not reduce the service life of a steel pipeline.

Often such a network operates in difficult conditions: underground and at a coolant temperature close to boiling point, and with water hammer reaching up to 15 atmospheres.

This operating mode cannot be mastered by plastic and. They would fail after 10-15 minutes of such work, but the steel structure will reliably last for a long time.

Dimensions

Steel pipes have the following standard sizes, which are taken into account during design developments:

Steel pipes have the following standard sizes, which are taken into account during design developments:

- Conditional passage. This is a conditional indicator that is used to describe the highway. This is the actual designation of the internal diameter, rounded to the nearest standard number. In accordance with GOST 28338-89, the value is rounded in the direction of increase. . For water supply pipes, the range of sizes ranges from 1 to 15 cm.

- Inner diameter. This is an exact figure for the volume inside, which is obtained by direct measurement. It is set in millimeters.

- O.D. This is the volume value with the calculation of the wall thickness.

- Wall thickness. This value is regulated.

The length in such a situation is not a constant value; in calculations it is taken into account as a pressure regulation factor and as an economic one. These systems are produced in measured short lengths, which means in the form of standard pieces. And they can be produced in a non-measured version. In this case, the dimensional values are from 4 to 12 meters.

Video: consider the characteristics

In systems for measuring water pipes, the inch system is used, and the dimensional values of pipes in all other cases are indicated in millimeters. For greater convenience, millimeter notations are used in practice along with inch notations.

In the metric version, mm is considered the standard of measurement, and this value is stable. In the imperial system, inches show not only standard measurement options, but also conditional ones. This is based on the characteristics of the carving.

The difference between the two types of products is visible at first glance. This is indicated by the size of the thread and the roundness of the threads on the pipe.

IMPORTANT! Inches are converted to mm as follows. Knowing that 1 inch equals 2.54 cm, you can accurately calculate the millimeter value of the pipe diameter. Round everything in the direction of increase.

Diameter table

The diameters of rolled steel pipes for water supply are shown in the table.

The standard diameters of these pipes, which are regulated by GOST, are shown in the following table.

| Conditional passage (DU) | Diameter volume outside |

| 6 | 10,2 |

| 8 | 13,5 |

| 10 | 17 |

| 15 | 21,3 |

| 20 | 26,8 |

| 25 | 33,5 |

| 32 | 42,3 |

| 40 | 48 |

| 50 | 60 |

| 65 | 75,5 |

| 80 | 88,5 |

| 90 | 101,3 |

| 100 | 114 |

| 125 | 114 |

| 150 | 165 |

Video

The volume needs to be known exactly. Such knowledge makes it possible to calculate the amount of medium carried through the pipeline. Such knowledge is especially valuable when arranging household systems.

For example, these indicators are used when you need to calculate the network so that in winter all rooms in the house are heated evenly. For each specific situation, such calculations are made using special tables.

If in doubt, it is better to call specialists for help. A properly and correctly installed steel network will serve very uninterruptedly. long time. In this way you can save not only nerves and time, but also finances.

An improperly installed water supply system can quickly become unusable, and repair work in this case is costly. It is for these reasons that competent, qualified assistance from craftsmen can save money.

Size chart of different water pipes

The following table shows the sizes of different water pipes.

| Conditional passage (DU) | Seam pipes (mm) | Seamless products (mm) |

| 6 | 10 | 10,2 |

| 8 | 13,5 | 13,5 |

| 10 | 17 | 16 |

| 15 | 21,3 | 20 |

| 20 | 26,8 | 26 |

| 25 | 33,5 | 32 |

| 32 | 42,3 | 42 |

| 40 | 48 | 45 |

| 50 | 60 | 57 |

| 65 | 75,5 | 76 |

| 80 | 88,5 | 89 |

| 90 | 101,3 | 102 |

| 100 | 114 | 108 |

| 125 | 114 | 133 |

| 150 | 165 | 159 |

Assortment

The range of steel pipes is shown in the table provided. Here is the data on how much the pipe weighs. The same regulatory standards determine the thickness of metal water pipes. It can also be found in the table provided.

| Conditional passage (DU) | Lungs | Ordinary | Reinforced | |||

| Wall thickness | Weight | Wall thickness | Weight | Wall thickness | Weight | |

| 6 | 1,8 | 0,3729 | 2 | 0,4044 | 2,5 | 0,4747 |

| 8 | 2 | 0,5672 | 2,2 | 0,6131 | 2,8 | 0,7389 |

| 10 | 2 | 0,7398 | 2,2 | 0,8030 | 2,8 | 0,9805 |

| 15 | 2,35 | 1,098 | – | – | – | – |

| 15 | 2,5 | 1,159 | 2,8 | 1,277 | 3,2 | 1,428 |

| 20 | 2,35 | 1,417 | – | – | – | – |

| 20 | 2,5 | 1,498 | 2,8 | 1,657 | 3,2 | 1,862 |

| 25 | 2,8 | 2,120 | 3,2 | 2,391 | 4 | 2,910 |

| 32 | 2,8 | 2,728 | 3,2 | 3,086 | 4 | 3,778 |

| 40 | 3 | 3,329 | 3,5 | 3,841 | 4 | 4,340 |

| 50 | 3 | 4,217 | 3,5 | 4,877 | 4,5 | 6.159 |

| 65 | 3,2 | 5,706 | 4 | 7,053 | 4,5 | 7,879 |

| 80 | 3,5 | 7,337 | 4 | 8,336 | 4,5 | 9,322 |

| 90 | 3,5 | 8,442 | 4 | 9,598 | 4,5 | 10,74 |

| 100 | 4 | 10,85 | 4,5 | 12,15 | 5 | 13,44 |

| 125 | 4 | 13,42 | 4,5 | 15,04 | 5,5 | 18,24 |

| 150 | 4 | 15,88 | 4,5 | 17,81 | 5,5 | 21,63 |

Steel water pipes are very common and there will be no problems purchasing them. This can be done through platforms for selecting the purchase of building materials.