The profile pipe gets its name from the fact that its cross-section is not round. In fact, any other product of this kind that does not have a circular cross-section can be called profiled. However, industry today produces several specific types, each of which is regulated by its own GOST.

In addition, everyone separate species suitable for a specific task, that is, it has a specific scope of application.

Some classification

At the moment we can highlight a large number of characteristics by which all materials of this kind can be classified among themselves. The key one is the profile shape. Profile products can take the following form:

- Rectangular (GOST 8645 68);

- Square (GOST 8639 82 or 8639 68);

- Flat oval. That is, those that have two straight sides and two in the form of half rings;

- Oval;

- With hollow ribs;

- With a different, special form.

Of course, the most common are square (GOST 8639 82 or 8639 68) and rectangular (GOST 8645 68).

In addition to the form, all such products are divided into types and according to the production method:

- Electric welded;

- Seamless.

Electric welded, among other things, are also divided into subtypes:

- Thin- and thick-walled;

- Galvanized and non-galvanized;

- Straight-seam and spiral-seam, and many others.

Seamless also have several subtypes:

- Seamless;

- Hot rolled;

- Galvanized and non-galvanized and many others.

Hot rolled and cold rolled - what is the difference

The difference is in the characteristics they have. Cold-rolled steel, as well as products made from it, will be more durable and resistant to various aggressive environments.

A sheet of steel undergoes rolling procedures, that is, it is cut and cut into sheets of smaller sizes, or into steel strips, which are then rolled and welded.

Hot Rolled Rectangular Tubes

Cold rolled steel undergoes a mandatory pickling procedure. The rolling process begins only after its completion. It must be said that this technology introduces some restrictions on thickness - up to 5 mm.

Because in the process hot rolling When the metal heats up and is subjected to some physical influences, its thickness over the entire area is constantly changing, that is, it is not the same. Cold-rolled steel sheets have the same thickness, a perfectly smooth surface and do not have scale that occurs during thermal cutting.

Seamless and seamless products

If you have figured out the source material, then now it remains to find out how a seamless profile pipe differs from one that has seams and what types of both there are.

Here it must be said right away that seamless products are more expensive and have higher technological characteristics, in contrast to those produced by electric welding.

All electric welded materials are obtained by forming the original sheet and then welding it. Depending on the shape of the seam, straight-seam and spiral-seam are distinguished.

For example, a profile pipe (GOST 8645 68) will have only one seam, which is located along the edge. Moreover, such a seam is straight.

Quite often, products are manufactured in a different way. The starting material is strip, that is, steel strip. It winds in a spiral. In this case, each seam is welded. This seam is called a spiral seam.

As for seamless materials, they are obtained by rolling a steel ingot. During the rolling process, a hole is formed, which subsequently takes on the required shape.

The most important difference between these two types of pipes is not even the presence or absence of a seam, but the strength characteristics. It is clear that seamless products will withstand much greater loads than electric welded ones.

Brief conclusion

As you can see, there are a huge number of types and subtypes of these products. However, even this is not all. All pipes differ in size. In addition, there is such a thing as thin-walled and thick-walled. There are no secrets here - thin-walled ones have a smaller wall thickness, unlike thick-walled materials.

All these parameters and characteristics can be found in square products (GOST 8639 82 or 8639 68) and rectangular (GOST 8645 68), as well as other types of profile products.

Bent closed profiles

This one occupies a special type among all the others. Today they have become the basis for the design of many buildings and structures. In fact, they form the backbone of the building. It is clear that none of them are small in size. The smallest ones available range in size from 15 cm. Quite often they are rectangular, but even more often they are square.

Their production is carried out in accordance with GOST 30245 2003. Products of this type are used for the construction of load-bearing supports, rods, columns and other similar elements.

Quite often you can see how ceilings are made from such materials.

These products can be produced from ordinary steel and from special alloy steel 09g2s (GOST is the same - 30245 2003). These metal products are used mainly in those regions where negative temperatures prevail for a long period.

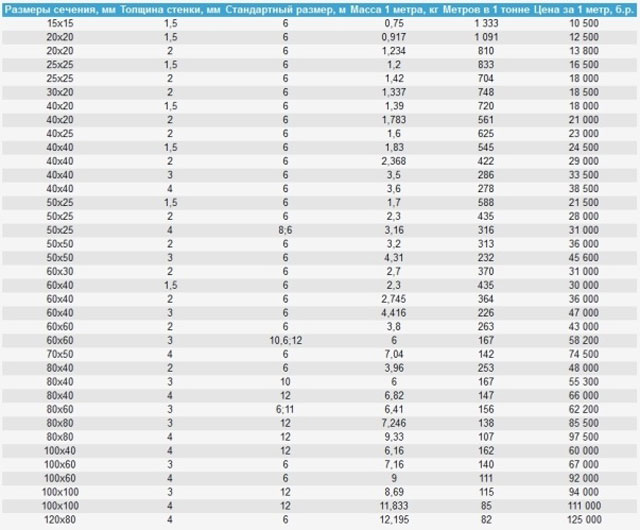

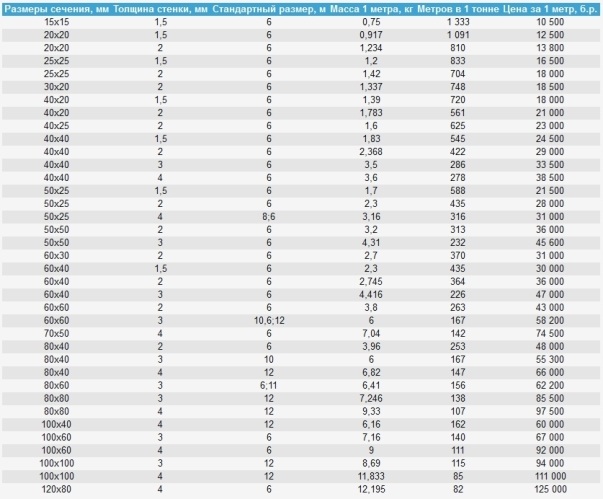

Sizes used

Among the huge variety of sizes, which are also diluted by the thickness of the wall, it is possible to identify those that are most often used, that is, they are in wide demand among private developers.

The rectangular profile pipe (8645 68) has the following dimensions: 2*1; 2.8*2.5; 3*1.5; 3*2; 4*2.5; 4*2.8; 5*2; 5*2.5; 5*3; 5*4; 6*3; 6*4; 8*4; 8*6; 10*5; 10*6; 10*8; 12*6; 12*8; 14*6; 15*10; 16*12; 16*8; 180*12.5; 200*10. Here all dimensions are indicated in centimeters.

It must be said that there are other sizes that are much larger than those presented. For example, the same bent pipes (30245 2003) can be produced with dimensions of 40 by 40 cm. It is worth mentioning the length. All of the above sizes can have any length, just like products 30245 2003. However, the latter, as a rule, are produced with a length of 2-3 meters. In this case, they are packed in packs, the maximum weight of which cannot exceed 10 tons.

More about bent profiles

Now we quite often mention the 30245 2003 standard. This is so because today the products of this particular standard become the basis of almost any building. Everyone often sees large supermarkets being built in a matter of days. This is the merit of this particular standard 30245 2003.

These products were specially designed for construction steel structures. They are made by molding a round pipe. Moreover, this product has one straight longitudinal seam. After welding, the process of compression with special tools occurs to a square or rectangular section.

Despite the similarity of this product (30245 2003), it should not be confused with ordinary rectangular pipes (8645 68) and square pipes (8639 68 or 8639 82)

Advantages and disadvantages

As you can see, the classification that the profile pipe has is quite broad. This is due to the fact that there are quite a lot of areas of application. Some of them require a large power reserve, some require less, so they use different types, manufactured according to different standards, as was evident in the example of standards 30245 2003 and 8645 68 with 8639 68 (82).

The assortment is also quite rich. This is caused by the same need for additional strength, which became possible due to an increase in wall thickness, for example.

It is impossible to say that such is truly huge selection, is already a great advantage. In fact, these products can be used in all possible sectors of our life. For example, if such special pipes as bent profile pipes (30245 2003) are used only in construction, then ordinary rectangular (8645 68) and square 8639 82 (68) can be used in private construction, and in the transportation of aggressive substances, and in mechanical engineering, and in many other sectors of heavy and light industry.

In addition to being universally used, specialized products have the following advantages:

- Small amount of metal required for production. This allows you to save up to a quarter of the total volume of steel from each construction site;

- High speed of installation of various structures;

- Not subject to combustion;

- Possibility of constructing even very complex structures.

The disadvantages include the constant enemy of steel - rust. Only timely special treatment will help avoid corrosion.

The scope of application of profile pipes is extremely diverse, so it is worth talking about their advantages and disadvantages in more detail. In this material we will talk about the range of profiled pipes, as well as what qualities of products you should pay attention to when purchasing them.

The very concept of “assortment” implies a wide variety of varieties and types of certain products, and in this context – profile pipes. As a rule, it helps to determine the presence various types products classified according to a number of parameters, which are presented by manufacturers or at wholesale or retail points of sale.

The full range of profile pipes includes all names of these products, manufactured in accordance with GOSTs, without exception, and also describes quality characteristics each category in all possible modifications.

In general, the classification of profile pipes can be carried out according to various indicators. One of the most significant characteristics is the profile shape.

![]()

There are the following types of products:

- oval;

- flat oval;

- square;

- rectangular shape;

- with hollow ribs;

- with a specially shaped profile.

It is worth noting that the range of steel profile pipes is developed separately for each type of profile in full compliance with GOSTs.

In addition, the variety of profile pipes is also determined by such factors as:

- method of production of pipe products - welded, cold- or hot-rolled);

- raw materials from which pipes are made;

- methods for processing end parts;

- industry where the use of certain types of pipes is envisaged.

By the size of the product range presented on the market by the manufacturer, one can judge its potential, capabilities and scale of production. And although expanding the list requires significant costs, it still indicates the stability of the enterprise.

Detailed description of the assortment

The widest variety of steel profiled pipes is represented by products with square and rectangular profiles, which differ in cross-section, length and wall thickness. And although metal is still one of the main types of material for their production, plastic analogues are gradually occupying an increasingly stronger position in the market.

Have gained very wide use profile pipes in the process of assembling metal structures for various industrial facilities. They are not only capable of replacing bars used for load-bearing structures, but also have a small weight and are inexpensive.

The only condition that must be taken into account during installation is compliance technical characteristics pipes and requirements for the construction site. To do this, it is necessary to make a preliminary calculation of the loads and determine the bearing capacity of a specific type of pipe.

In addition, when choosing the type of pipes, it is worth considering the weight per linear meter of such products.

If we talk about the production method, there are hot- and cold-formed profile pipes. At the same time, classification according to GOST implies division into profile welded and cold-deformed pipes. Depending on the purpose of the pipes, they may be coated with zinc.

Most often, square rectangular pipes with the following parameters are in demand:

- 15×15 mm;

- 20×20 mm;

- 25×25 mm;

- 30×30 mm;

- 40×40 mm;

- 60×60 mm;

- 80×80 mm;

- 100×160 mm;

- 100×100 mm.

Advantages and disadvantages of various profiled pipes

All pipes whose cross-sectional shape is not round are called profiled. The most common are square and rectangular steel pipes. The most common profile sizes are 25, 60, 100 mm and 40×80 mm, 50×50 mm and 40×100 mm.

Products made from profiles whose cross-section exceeds 10 cm are fairly dense metal bars with four stiffening ribs and low weight, so they are often used when assembling load-bearing parts of structures. For engineering projects As a rule, profiled products with a cross section of 60 mm are used, since they have good bending rigidity.

It is worth noting that thanks to the variety of standard sizes of profiled pipes produced, it has become possible to construct increasingly complex structures.

Among the main advantages of profile pipes are:

- low metal content, which allows saving up to 25% of raw materials for the construction of a particular facility;

- due to the ease of installation, the construction of the structure is carried out very quickly;

- convenience in sanitary and antiseptic treatment, hygiene;

- full compliance with standards fire safety;

- possibility of assembling structures of increased complexity.

Area of use of profile pipes

Due to the variety of sections and shapes of profile pipes, their scope of application is extremely wide.

In particular, the use of such products would be appropriate in the following cases:

- To assemble the frame of buildings, if there is a need to save metal, profile pipes with a cross-section of 60×30 mm are often used.

- Pipes with dimensions of 15×15 mm, 40×60 mm, 60 mm and 100 mm are acceptable as structural elements.

- Among the advantages of products with parameters 25 × 25 mm and others, one can name the moment of resistance of a profile pipe, that is, its strength, low weight, high speed and ease of assembly of metal structures from them, as well as high tightness.

- The good performance characteristics of profile pipes, as well as their versatility, make it possible to use them in almost any field of activity. In particular, profiled products with dimensions of 25×250 mm are actively used in the mechanical engineering industry. But 60x30 mm pipes are in demand for assembling billboards and banners.

- In the construction of large residential buildings, public buildings, as well as warehouses and garages, pipes with parameters of 40x60 mm, as well as many other types, are in great demand.

Thus, it can be noted that pipes of various profiles, in particular square, rectangular and other types, are very common in the construction of objects for various purposes. If you need to build lightweight partitions or structures that will not bear a large load, then profiled pipes with thin walls are perfect for these purposes.

In many branches of modern industry, rectangular pipes are very actively used; the range of such products makes it possible to use them for the manufacture of furniture, car frames, various types fencing and metal structures, greenhouses and other structures.

1 Regulatory documentation and assortment of rectangular steel pipes (GOST)

Currently, the profile products we are interested in can be manufactured using three technologies and can be:

- seamless cold rolled;

- electric welded;

- seamless hot rolled;

Regardless of which production method is used, all products must comply with the 1968 State Standard 8645 in terms of quality.

According to his requirements, finished products can have dimensions from 15x10 to 180x150 and 230x100 millimeters. The cross-sectional area of the products varies from 0.44 (for pipes 15x10 mm) to 70.97 square centimeters (180x150 mm). The largest cross-section of pipes with dimensions of 196x170 mm is 113.24 sq. cm.

The wall thickness of the described products with a rectangular profile can have the following indicators in millimeters:

- 6–12.

Rectangular pipes 196x170 mm are produced with walls of 18 mm, and 180x145 mm - as much as 20 mm. They cannot have other thicknesses, since they are produced for specific purposes (installation of ultra-reliable structures). Most products with smaller dimensions are usually made with different wall thicknesses.

Another important indicator of rectangular pipes, which is strictly regulated by GOST, is their weight per linear meter. For products 15x10 mm it is equal to 0.348 kg (with a wall thickness of 1 mm), for pipes 196x170 mm - 88.89 kg.

Note that a number of rectangular structures, according to their geometric parameters, are classified as special-purpose pipes. State Standard 8645–68 provides a complete range of such products (dimensions in millimeters):

- 28x25 (walls – 2.5, 2 and 1.5);

- 40x28 (1.5–2.5);

- 40x25 (1.5);

- 90x50 (3);

- 70x50 (7);

- 230x100 (8);

- 140x60 (3);

- 150x60 (7);

- 200x120 (8);

- 190x120 (12);

- 160x130 (8);

- 196x170 (18);

- 180x145 (20).

2 Rectangular steel pipes - assortment and permissible deviations

Limit deviations of external dimensions of pipes according to the standard:

- for high precision products: ±1.25% (hot rolled), ±0.25 mm (cold rolled and welded up to 30 mm), ±0.3 mm (cold rolled and welded 30–50 mm), ±0.8% (cold rolled and welded more than 50 mm);

- for products of normal accuracy: respectively, ±1.5%, ±0.3 mm, ±0.4 mm, ±0.8%.

Maximum concavity of the sides, or their convexity (all values are given in millimeters):

- products manufactured using seamless hot-rolled technology: 0.5 and 0.75 (high and normal precision pipes, respectively) for structures with sides no more than 50 mm; 0.8 and 1 (from 50 to 70); 1.2 and 1.5 (from 70 to 100); 1.5 and 2 (from 100 or more);

- products made using electric-welded and cold-rolled technology: 0.5 for pipes no more than 50 mm; 0.5 and 0.75 (from 50 to 70 mm); 0.8 and 1 (from 70 and above).

Deviations (largest) in wall thickness:

- ±10% for electric welded pipes any accuracy class;

- ±12.5% for cold- and hot-deformed pipes of any accuracy with walls no more than 3.5 mm; 10 and 12.5% for products with walls higher than 3.5 mm.

The twist rate can be two degrees per meter finished products or negotiate with the buyer of the structures separately. are more suitable for situations where total weight These metal structures are relatively small. They are more wear-resistant and aesthetically pleasing.

However, “simple” rectangular pipe products, from the point of view of external attractiveness, are many times preferable to the popular and often used in metal structures. The latter, however, is characterized by greater bending strength. For this reason, I-beams are often preferred over profile products.

The surface of stainless steel products is usually polished or ground. Such products are subject to less stringent requirements regarding their strength, which causes some (very minor) differences in the manufacturing process of standard and stainless steel pipes.

The former are made from strips or rods, and “stainless steel” is made from welded finished pipes, which are welded using the induction method (HF). This welding technology is inexpensive, while the total cost of the manufacturing process of stainless steel profile structures is quite high.

There is no separate State standard for such pipes, so their assortment can be found in GOST 8645, which we described in detail. But there are State standards for raw materials intended for the production of stainless profiles:

- 9940–81 – hot rolled;

- 11068–81 – electric welded;

- 9941–81 – cold rolled.

When looking through GOST 8645, do not forget that they have a higher specific gravity (due to the higher density) of one meter (linear). For the rest, you can safely rely on it.

4 Where are rectangular profiles used?

As mentioned, the wide range of profile products described makes it possible to use them in many industries production activities. A variety of sizes and weights allow the use of rectangular pipes for the release of:

Technical requirements for profile pipes are regulated by GOST 13662-86. This standard applies to profile hot-formed, cold-formed, electric-welded and electric-welded cold-formed general-purpose carbon steel pipes.

Assortment

The dimensions of the pipes must comply with those specified in GOST 8638-57, GOST 8639-82, GOST 8642-68, GOST 8644-68, GOST 8645-68 and GOST 8646-68. Maximum deviations in size must correspond to those specified in GOST 8639-82.

Steel grades

Pipes are made from steel grades St2sp, St2ps, St2kp, St4sp, St4ps, St4kp according to DSTU 2651:2005 and grades 10, 10ps, 20, 35, 45, 08kp - according to GOST 1050. Pipes are made by heat treatment or without heat treatment.

Square steel pipes (according to GOST 8639-82)

The range of square pipes is regulated by GOST 8639-82. This standard applies to seamless hot-deformed, cold-deformed and electric-welded steel pipes.

A– outer size; S– wall thickness;

R– radius of curvature.

Rice. 4.2. Square steel pipe

Weight of pipes M pipes determined by the formula:

Where L – total length of pipes, m; g beat r = 7850 kg/m3.

For a regular square pipe:

(kg/m),

at:

(kg/m),

Where A– external pipe size in mm; S– wall thickness in mm; R– radius of curvature in mm.

Assortment

Pipes external dimensions:

- from 10 to 120 mm with a wall thickness from 1.0 to 8.0 mm are produced cold-formed;

- from 60 to 180 mm with a wall thickness from 4.0 to 14.0 mm are made hot-deformed;

- from 10 to 100 mm with a wall thickness from 1.0 to 5.0 mm are made by electric welding.

Table 4.11. Dimensions and theoretical weight of 1 m square pipes

| Outer size, Ah, mm |

Wall thickness, S, mm |

Weight 1 m, kg |

Meters to 1 ton, m |

| 10 | 1 | 0,2691 | 3716 |

| 15 | 1 | 0,4261 | 2347 |

| 1,5 | 0,6055 | 1651 | |

| 20 | 1 | 0,5831 | 1715 |

| 1,5 | 0,8410 | 1189 | |

| 2 | 1,076 | 928,9 | |

| 25 | 1 | 0,7401 | 1351 |

| 1,5 | 1,077 | 928,9 | |

| 2 | 1,390 | 719,2 | |

| 2,5 | 1,682 | 594,5 | |

| 3 | 1,951 | 512,5 | |

| 30 | 2 | 1,704 | 586,7 |

| 2,5 | 2,075 | 482,0 | |

| 3 | 2,422 | 412,9 | |

| 3,5 | 2,747 | 364,0 | |

| 4 | 3,050 | 327,9 | |

| 35 | 2 | 2,018 | 495,4 |

| 2,5 | 2,467 | 405,3 | |

| 3 | 2,893 | 345,6 | |

| 3,5 | 3,297 | 303,3 | |

| 4 | 3,678 | 271,9 | |

| 5 | 4,373 | 228,7 | |

| 40 | 2 | 2,332 | 428,7 |

| 2,5 | 2,860 | 349,7 | |

| 3 | 3,364 | 297,3 | |

| 3,5 | 3,846 | 260,0 | |

| 4 | 4,306 | 232,2 | |

| 5 | 5,158 | 193,9 | |

| 40 | 6 | 5,920 | 168,9 |

| 42 | 3 | 3,553 | 281,5 |

| 3,5 | 4,066 | 245,9 | |

| 4 | 4,557 | 219,4 | |

| 5 | 5,472 | 182,7 | |

| 6 | 6,297 | 158,8 | |

| 45 | 3 | 3,835 | 260,7 |

| 3,5 | 4,396 | 227,5 | |

| 4 | 4,934 | 202,7 | |

| 5 | 5,943 | 168,3 | |

| 6 | 6,862 | 145,7 | |

| 7 | 7,692 | 130,0 | |

| 8 | 8,432 | 118,6 | |

| 50 | 3 | 4,306 | 232,2 |

| 3,5 | 4,945 | 202,2 | |

| 4 | 5,562 | 179,8 | |

| 5 | 6,728 | 148,6 | |

| 6 | 7,804 | 128,1 | |

| 7 | 8,791 | 113,8 | |

| 8 | 9,688 | 103,2 | |

| 60 | 3* | 5,248 | 190,5 |

| 3,5 | 6,044 | 165,4 | |

| 4 | 6,818 | 146,7 | |

| 5 | 8,298 | 120,5 | |

| 6 | 9,688 | 103,2 | |

| 7 | 10,99 | 91,00 | |

| 8 | 12,20 | 81,97 | |

| 70 | 4 | 8,074 | 123,9 |

| 5 | 9,868 | 101,3 | |

| 6 | 11,57 | 86,41 | |

| 7 | 13,19 | 75,83 | |

| 8 | 14,71 | 67,97 | |

| 80 | 4 | 9,330 | 107,2 |

| 5 | 11,44 | 87,43 | |

| 6 | 13,46 | 74,31 | |

| 7 | 15,39 | 65,00 | |

| 8 | 17,22 | 58,06 | |

| 90 | 5 | 13,01 | 76,88 |

| 6 | 15,34 | 65,19 | |

| 7 | 17,58 | 56,87 | |

| 8 | 19,74 | 50,67 | |

| 100 | 6 | 17,22 | 58,06 |

| 7 | 19,78 | 50,55 | |

| 8 | 22,25 | 44,95 | |

| 9 | 24,62 | 40,61 | |

| 110 | 6 | 19,11 | 52,33 |

| 7 | 21,98 | 45,50 | |

| 8 | 24,76 | 40,39 | |

| 9 | 27,45 | 36,43 | |

| 120 | 6 | 20,99 | 47,64 |

| 7 | 24,18 | 41,36 | |

| 8 | 27,27 | 36,67 | |

| 9 | 30,28 | 33,03 | |

| 140 | 6 | 24,76 | 40,39 |

| 7 | 28,57 | 35,00 | |

| 8 | 32,30 | 30,96 | |

| 9 | 35,93 | 27,83 | |

| 150 | 7 | 30,77 | 32,50 |

| 8 | 34,81 | 28,73 | |

| 9 | 38,75 | 25,80 | |

| 10 | 42,61 | 23,47 | |

| 180 | 8 | 42,34 | 23,62 |

| 9 | 47,23 | 21,17 | |

| 10 | 52,03 | 19,22 | |

| 12 | 61,36 | 16,30 | |

| 14 | 70,33 | 14,22 | |

| Special sizes pipes | |||

| 32 | 4 | 3,301 | 302,9 |

| 36 | 4 | 3,804 | 262,9 |

| 40 | 2 | 2,332 | 428,7 |

| 65 | 6 | 10,63 | 94,07 |

* – Non-standard size.

Notes:

- The mass of 1 m of pipes is calculated based on the nominal dimensions at R=1.5·S and the material density of 7850 kg/m3. The calculated value is a reference value.

Uncover

Pipes are manufactured:

- unmeasured length:

- seamless cold-deformed and electric-welded - from 1.5 to 9 m;

- measured length:

- seamless hot-deformed – from 4 to 12.5 m,

- seamless cold-deformed – from 4.5 to 9 m,

- electric welded – from 5 to 9 m;

- length, multiple of measured:

- seamless hot-deformed - from 4 to 12.5 m with an allowance for each cut of 5 mm;

- seamless cold-deformed - from 1.5 to 9 m with an allowance for each cut of 5 mm;

- electric welded - any multiplicity not exceeding the lower limit established for measuring pipes.

The total length of multiple pipes must not exceed the upper limit of the gauge pipes. The allowance for each multiple is set to 5 mm (unless another allowance is specified in the order) and is included in each ordered multiple.

In the cross section of the pipe, the deviation from the right angle should not exceed ±1.5°.

The curvature of the pipes should not exceed 2 mm per 1 m of length.

Technical requirements

Technical requirements must comply with GOST 13663-86.

Examples of symbols

Pipes with an outer size of 40 mm, a wall thickness of 3 mm, a length multiple of 1250 mm, made of steel grade 10, group B GOST 13663-86:

The same, of unmeasured length:

| Pipe | 40 x 40 x 3 GOST 8639-82 |

| B 10 GOST 13663-86 |

Rectangular steel pipes (according to GOST 8645-68)

The range of rectangular pipes is regulated by GOST 8645-68. This standard applies to seamless hot-rolled, cold-drawn and electric-welded rectangular steel pipes.

A and B– external dimensions; S– wall thickness;

R– radius of curvature.

Rice. 4.3. Rectangular steel pipe

Weight of pipes Mtub determined by the formula:

Where L

– total length of pipes, m;

g beat

– theoretical mass of 1 m of pipe, calculated from its nominal dimensions, at the density of steel r

= 7850 kg/m3.

For a regular rectangular pipe:

(kg/m),

at:

(kg/m),

where A and B are the external dimensions of the pipe in mm; S – wall thickness in mm; R – radius of curvature in mm.

Table 4.12. Dimensions and theoretical weight of 1 m rectangular pipes

| Ah, mm | V, mm | S, mm | Weight 1 m, kg | Meters per ton, m |

| 15 | 10 | 1 | 0,3476 | 2877 |

| 1,5 | 0,4878 | 2050 | ||

| 2 | 0,6055 | 1652 | ||

| 20 | 10 | 1 | 0,4261 | 2347 |

| 1,5 | 0,6055 | 1651 | ||

| 2 | 0,7625 | 1311 | ||

| 15 | 1 | 0,5046 | 1982 | |

| 1,5 | 0,7233 | 1383 | ||

| 2 | 0,9195 | 1088 | ||

| 2,5 | 1,093 | 915 | ||

| 25 | 10 | 1 | 0,5046 | 1982 |

| 1,5 | 0,7233 | 1383 | ||

| 2 | 0,9195 | 1088 | ||

| 2,5 | 1,093 | 914,7 | ||

| 15 | 1 | 0,5831 | 1715 | |

| 1,5 | 0,8410 | 1189 | ||

| 2 | 1,076 | 928,9 | ||

| 2,5 | 1,290 | 775,5 | ||

| 30 | 10 | 1 | 0,5831 | 1715 |

| 1,5 | 0,8410 | 1189 | ||

| 2 | 1,076 | 928,9 | ||

| 2,5 | 1,290 | 775,5 | ||

| 3 | 1,480 | 675,6 | ||

| 15 | 1 | 0,6616 | 1511 | |

| 1,5 | 0,9588 | 1043 | ||

| 2 | 1,233 | 810,7 | ||

| 2,5 | 1,486 | 673,1 | ||

| 3 | 1,716 | 582,9 | ||

| 20 | 1 | 0,7401 | 1351 | |

| 1,5 | 1,077 | 928,9 | ||

| 2 | 1,390 | 719,2 | ||

| 2,5 | 1,682 | 594,5 | ||

| 3 | 1,951 | 512,5 | ||

| 35 | 15 | 1,5 | 1,077 | 928,9 |

| 2 | 1,390 | 719,2 | ||

| 2,5 | 1,682 | 594,5 | ||

| 3 | 1,951 | 512,5 | ||

| 3,5 | 2,198 | 455,0 | ||

| 20 | 1,5 | 1,194 | 837,3 | |

| 2 | 1,547 | 646,2 | ||

| 2,5 | 1,878 | 532,4 | ||

| 3 | 2,187 | 457,3 | ||

| 3,5 | 2,473 | 404,4 | ||

| 25 | 1,5 | 1,312 | 762,2 | |

| 2 | 1,704 | 586,7 | ||

| 2,5 | 2,075 | 482,0 | ||

| 3 | 2,422 | 412,9 | ||

| 3,5 | 2,747 | 364,0 | ||

| 40 | 15 | 2 | 1,547 | 646,2 |

| 2,5 | 1,878 | 532,4 | ||

| 3 | 2,187 | 457,3 | ||

| 3,5 | 2,473 | 404,4 | ||

| 4 | 2,736 | 365,5 | ||

| 20 | 2 | 1,704 | 586,7 | |

| 2,5 | 2,075 | 482,0 | ||

| 3 | 2,422 | 412,9 | ||

| 3,5 | 2,747 | 364,0 | ||

| 4 | 3,050 | 327,9 | ||

| 25 | 2 | 1,861 | 537,2 | |

| 2,5 | 2,271 | 440,4 | ||

| 3 | 2,658 | 376,3 | ||

| 3,5 | 3,022 | 330,9 | ||

| 4 | 3,364 | 297,3 | ||

| 30 | 2 | 2,018 | 495,4 | |

| 2,5 | 2,467 | 405,3 | ||

| 3 | 2,893 | 345,6 | ||

| 3,5 | 3,297 | 303,3 | ||

| 4 | 3,678 | 271,9 | ||

| 42 | 20 | 2 | 1,767 | 565,8 |

| 2,5 | 2,153 | 464,5 | ||

| 3 | 2,516 | 397,4 | ||

| 3,5 | 2,857 | 350,0 | ||

| 4 | 3,176 | 314,9 | ||

| 30 | 2 | 2,081 | 480,5 | |

| 2,5 | 2,546 | 392,8 | ||

| 3 | 2,987 | 334,7 | ||

| 3,5 | 3,407 | 293,5 | ||

| 4 | 3,804 | 262,9 | ||

| 45 | 20 | 2 | 1,861 | 537,2 |

| 2,5 | 2,271 | 440,4 | ||

| 3 | 2,658 | 376,3 | ||

| 3,5 | 3,022 | 330,9 | ||

| 4 | 3,364 | 297,3 | ||

| 30 | 2 | 2,175 | 459,7 | |

| 2,5 | 2,663 | 375,5 | ||

| 3 | 3,129 | 319,6 | ||

| 3,5 | 3,572 | 280,0 | ||

| 4 | 3,992 | 250,5 | ||

| 50 | 25 | 2 | 2,175 | 459,7 |

| 2,5 | 2,663 | 375,5 | ||

| 3 | 3,129 | 319,6 | ||

| 3,5 | 3,572 | 280,0 | ||

| 4 | 3,992 | 250,5 | ||

| 30 | 2 | 2,332 | 428,7 | |

| 2,5 | 2,860 | 349,7 | ||

| 3 | 3,364 | 297,3 | ||

| 3,5 | 3,846 | 260,0 | ||

| 4 | 4,306 | 232,2 | ||

| 35 | 2 | 2,489 | 401,7 | |

| 2,5 | 3,056 | 327,2 | ||

| 3 | 3,600 | 277,8 | ||

| 3,5 | 4,121 | 242,7 | ||

| 4 | 4,620 | 216,5 | ||

| 40 | 2 | 2,646 | 377,9 | |

| 2,5 | 3,252 | 307,5 | ||

| 3 | 3,835 | 260,7 | ||

| 3,5 | 4,396 | 227,5 | ||

| 4 | 4,934 | 202,7 | ||

| 60 | 25 | 2,5 | 3,056 | 327,2 |

| 3 | 3,600 | 277,8 | ||

| 3,5 | 4,121 | 242,7 | ||

| 4 | 4,620 | 216,5 | ||

| 5 | 5,551 | 180,2 | ||

| 30 | 2,5 | 3,252 | 307,5 | |

| 3 | 3,835 | 260,7 | ||

| 3,5 | 4,396 | 227,5 | ||

| 4 | 4,934 | 202,7 | ||

| 5 | 5,943 | 168,3 | ||

| 40 | 3 | 4,306 | 232,2 | |

| 3,5 | 4,945 | 202,2 | ||

| 4 | 5,562 | 179,8 | ||

| 5 | 6,728 | 148,6 | ||

| 70 | 30 | 3 | 4,306 | 232,2 |

| 3,5 | 4,945 | 202,2 | ||

| 4 | 5,562 | 179,8 | ||

| 5 | 6,728 | 148,6 | ||

| 6 | 7,804 | 128,1 | ||

| 40 | 3 | 4,777 | 209,3 | |

| 3,5 | 5,495 | 182,0 | ||

| 4 | 6,190 | 161,6 | ||

| 5 | 7,513 | 133,1 | ||

| 6 | 8,746 | 114,3 | ||

| 50 | 3 | 5,248 | 190,5 | |

| 3,5 | 6,044 | 165,4 | ||

| 4 | 6,818 | 146,7 | ||

| 5 | 8,298 | 120,5 | ||

| 6 | 9,688 | 103,2 | ||

| 80 | 40 | 3 | 5,248 | 190,5 |

| 3,5 | 6,044 | 165,4 | ||

| 4 | 6,818 | 146,7 | ||

| 5 | 8,298 | 120,5 | ||

| 6 | 9,688 | 103,2 | ||

| 7 | 10,99 | 91,00 | ||

| 50 | 3 | 5,719 | 174,9 | |

| 3,5 | 6,594 | 151,7 | ||

| 4 | 7,446 | 134,3 | ||

| 60 | 3,5 | 7,143 | 140,0 | |

| 4 | 8,074 | 123,9 | ||

| 5 | 9,868 | 101,3 | ||

| 6 | 11,57 | 86,41 | ||

| 7 | 13,19 | 75,83 | ||

| 90 | 40 | 3,5 | 6,594 | 151,7 |

| 4 | 7,446 | 134,3 | ||

| 5 | 9,083 | 110,1 | ||

| 6 | 10,63 | 94,07 | ||

| 7 | 12,09 | 82,73 | ||

| 60 | 4 | 8,702 | 114,9 | |

| 5 | 10,65 | 93,87 | ||

| 6 | 12,51 | 79,91 | ||

| 7 | 14,29 | 70,00 | ||

| 100 | 40 | 4 | 8,074 | 123,9 |

| 5 | 9,868 | 101,3 | ||

| 6 | 11,57 | 86,41 | ||

| 7 | 13,19 | 75,83 | ||

| 50 | 4 | 8,702 | 114,9 | |

| 5 | 10,65 | 93,87 | ||

| 6 | 12,51 | 79,91 | ||

| 7 | 14,29 | 70,00 | ||

| 70 | 4 | 9,958 | 100,4 | |

| 5 | 12,22 | 81,81 | ||

| 6 | 14,40 | 69,45 | ||

| 7 | 16,48 | 60,66 | ||

| 110 | 40 | 4 | 8,702 | 114,9 |

| 5 | 10,65 | 93,87 | ||

| 6 | 12,51 | 79,91 | ||

| 7 | 14,29 | 70,00 | ||

| 50 | 4 | 9,330 | 107,2 | |

| 5 | 11,44 | 87,43 | ||

| 6 | 13,46 | 74,31 | ||

| 7 | 15,39 | 65,00 | ||

| 60 | 4 | 9,958 | 100,4 | |

| 5 | 12,22 | 81,81 | ||

| 6 | 14,40 | 69,45 | ||

| 7 | 16,48 | 60,66 | ||

| 120 | 40 | 5 | 11,44 | 87,43 |

| 6 | 13,46 | 74,31 | ||

| 7 | 15,39 | 65,00 | ||

| 8 | 17,22 | 58,06 | ||

| 60 | 5 | 13,01 | 76,88 | |

| 6 | 15,34 | 65,19 | ||

| 7 | 17,58 | 56,87 | ||

| 8 | 19,74 | 50,67 | ||

| 80 | 5 | 14,58 | 68,60 | |

| 6 | 17,22 | 58,06 | ||

| 7 | 19,78 | 50,55 | ||

| 8 | 22,25 | 44,95 | ||

| 140 | 60 | 5 | 14,58 | 68,60 |

| 6 | 17,22 | 58,06 | ||

| 7 | 19,78 | 50,55 | ||

| 8 | 22,25 | 44,95 | ||

| 80 | 5 | 16,15 | 61,93 | |

| 6 | 19,11 | 52,33 | ||

| 7 | 21,98 | 45,50 | ||

| 8 | 24,76 | 40,39 | ||

| 120 | 6 | 22,88 | 43,71 | |

| 7 | 26,38 | 37,91 | ||

| 8 | 29,78 | 33,58 | ||

| 9 | 33,10 | 30,21 | ||

| 150 | 80 | 6 | 20,05 | 49,87 |

| 7 | 23,08 | 43,33 | ||

| 8 | 26,02 | 38,44 | ||

| 9 | 28,86 | 34,65 | ||

| 10 | 31,62 | 31,62 | ||

| 100 | 6 | 21,93 | 45,59 | |

| 7 | 25,28 | 39,56 | ||

| 8 | 28,53 | 35,05 | ||

| 9 | 31,69 | 31,56 | ||

| 10 | 34,76 | 28,77 | ||

| 180 | 80 | 7 | 26,38 | 37,91 |

| 8 | 29,78 | 33,58 | ||

| 9 | 33,10 | 30,21 | ||

| 10 | 36,33 | 27,52 | ||

| 12 | 42,52 | 23,52 | ||

| 100 | 8 | 32,30 | 30,96 | |

| 9 | 35,93 | 27,83 | ||

| 10 | 39,47 | 25,33 | ||

| 12 | 46,29 | 21,60 | ||

| 150 | 8 | 38,58 | 25,92 | |

| 9 | 42,99 | 23,26 | ||

| 10 | 47,32 | 21,13 | ||

| 12 | 55,71 | 17,95 | ||

| Special sizes pipes | ||||

| 28 | 25 | 1,5 | 1,147 | 871,7 |

| 28 | 25 | 2 | 1,485 | 673,5 |

| 28 | 25 | 2,5 | 1,800 | 555,6 |

| 40 | 25 | 1,5 | 1,430 | 699,4 |

| 40 | 28 | l.5 | 1,500 | 666,5 |

| 40 | 28 | 2 | 1,956 | 511,3 |

| 40 | 28 | 2,5 | 2,389 | 418,7 |

| 70 | 50 | 7 | 10,99 | 91,00 |

| 90 | 50 | 3 | 6,190 | 161,5 |

| 140 | 60 | 3 | 9,016 | 110,9 |

| 150 | 60 | 7 | 20,88 | 47,89 |

| 160 | 130 | 8 | 33,55 | 29,80 |

| 180 | 145 | 20 | 84,10 | 11,89 |

| 190 | 120 | 12 | 51,94 | 19,25 |

| 196 | 170 | 18 | 88,89 | 11,25 |

| 200 | 120 | 8 | 37,32 | 26,80 |

| 230 | 100 | 8 | 38,58 | 25,92 |

Notes:

- The mass of 1 m of pipes is calculated based on the nominal dimensions at R=1.5·S and the material density of 7850 kg/m 3 . The calculated value is a reference value.

- The radius of curvature R should be no more than 2·S.

Examples of symbols

Pipes with external dimensions A=40 mm, B=25 mm with a wall thickness of 3 mm, length multiple of 1250 mm, made of steel grade 10, group B GOST 13663-86:

The same, of unmeasured length:

| Pipe | 40 x 25 x 3 GOST 8645-68 |

| B 10 GOST 13663-86 |

Current standards

This article will consider the range of profile pipes, and the main advantages and disadvantages of profile pipes of various sections.

Profile pipes are used in a variety of areas, therefore there are quite a large number of varieties of such pipes, and therefore a concept was introduced that helps to more conveniently and clearly understand existing species, which include profile pipes - assortment.

Important: if we discard the profile pipes themselves, assortment is a concept derived from the word “grade”, thus the assortment of any product is a list of names of this product presented on the market.

Most often, the assortment is the main indicator of the availability of specific types of pipes at the manufacturer or supplier store.

It is a table or list that lists the types of pipes, corresponding to square, rectangular profile pipe - the assortment should include all available varieties, giving for each category all the names with their characteristics.

The range of profile pipes includes a wide variety of types of rolled pipes.

Their classification can be carried out according to various parameters, the key of which is the shape of the profile, depending on which they distinguish:

- Rectangular;

- Square;

- Flat oval;

- Oval;

- Pipes having hollow ribs;

- Pipes with special profiles.

In this case, the assortment of profile pipes is carried out separately for each type and is regulated by the relevant GOST.

Each listed type of pipe includes many varieties according to different parameters, such as:

- Production method (cold and hot rolled, welded);

- Materials used in production;

- End processing;

- Purpose of pipes and many others.

In the case of a manufacturer, the assortment is its representation on the market and an indicator of development. The larger the range of profile pipes presented, the better, despite the significantly higher costs and required production capacity.

More information about the range

Depending on the cross-section, profile pipes are most often classified into square and rectangular, having different lengths and thicknesses.

The main material for their production is metal, which is now gradually being replaced by plastic.

When installing various metal structures, you should also correctly select profiled metal products that have the required technical characteristics.

In this case, it is necessary to correctly calculate the optimal load-bearing capacity for profile pipes, taking into account the possibility of using both square and rectangular profile pipes.

Important: you should also keep in mind the different weight and cross-section of a linear meter of pipes of each type.

In addition, it should be noted that profile pipes are produced both hot-deformed and cold-deformed, and in accordance with GOST they are also divided into electric-welded and cold-deformed profiles, which may or may not have a zinc coating, depending on the application of a particular product.

At the same time, the most popular in the construction market are profile pipes with the following dimensions:

- 15x15;

- 20x20;

- 25x25;

- 30x30;

- 40x40;

- 60x60;

- 80x80;

- 100x60;

- 100x100.

Pros and cons of profile pipes from the range

Regardless of the diameter, profile pipes are hardware with a cross-section different from round. Most often, the cross-section of profile pipes is square and rectangular, and the most used profiles are 25, 60, 100 mm, as well as 40x80, 40x100 and 50x50.

The profile pipes with a diameter of 100 mm and above included in the assortment, which are metal beams with four stiffening ribs and a low specific gravity, are most often used as structural elements. Profile pipes 60 mm have good rigidity bending, which allows them to be widely used in construction and installation of engineering systems.

Important: you should also take into account that the manufactured range of profile products allows you to reduce metal costs and use more complex structural elements.

Profile pipes have the following advantages:

- Low metal consumption, providing up to 25% metal savings for the construction of one facility;

- Maximum speed of installation of buildings and structures;

- Compliance with sanitary and hygienic standards, ease of disinfection and sanitization;

- Compliance with fire safety rules and regulations;

- The ability to quickly erect even the most complex structures.

About the use of profile pipes

As already mentioned, metal profile pipes have different shapes and cross-sections, which allows them to be used in various fields of human activity:

- Profile pipes 60x30, which have low metal consumption, are effectively used when it is necessary to save metal when constructing the frame of buildings or structures;

- The most common today are pipes of 15x15, 40x60, 60 and 100 mm, which are most often used as structural elements;

- Profile pipes 25x25 and other sizes have a number of advantages over structures using other rolled metal products, such as low weight, high strength, convenience and ease of installation and almost absolute tightness;

- Due to their versatility and excellent performance characteristics, profile products are used in a wide variety of industries, for example:

- Profile pipe 25x250 is used in mechanical engineering;

- Profile pipe 60x30 is used in the field of advertising in the production of various frames and panels.

Profile pipes of 40x60 and other sections are very popular and are currently used in the construction of almost all structures, warehouses, etc.

To summarize, we can say that profile pipes are indispensable in construction during construction various designs and frames. In addition, thin-walled profile pipes are used for the manufacture of partitions and other devices that do not bear a certain load.