No matter how high-quality and modern the roofing is, it is necessary to think in advance about protecting the most vulnerable places, and above all the joints of the material, from moisture and other destructive influences. Roof sealant does a good job of insulation: with its help you can cope with the task quite quickly and without unnecessary hassle. Roofing sealants are polymeric materials based on compounds of various rubbers and bitumen. Due to their ductility, flexibility, moisture and air tightness, as well as excellent adhesion, they can be used to insulate joints of all known materials. Moreover, the roofing sealant can be used in the temperature range -55 ... +80 o C.

Varieties

Depending on the base, it is customary to distinguish several main types of sealant:

- acrylic;

- silicone (rubber);

- bitumen;

- polyurethane.

Each has its own specifics and area of application, which is why, before going to the nearest hardware store, you should have a good understanding of each variety - this will help you make the right choice.

Silicone sealant

Perhaps the most popular roofing sealant is silicone. High moisture- and air-tight properties, plasticity and excellent adhesion to most surfaces are largely ensured by the base - yloxane rubber. Moreover, it is silicone (rubber) roofing sealant that can withstand high temperatures (even prolonged heating), as well as direct sun rays, which makes it suitable for sealing roofs even made of natural tiles.

Acrylic sealant

Acrylic-based roofing sealant is most often used to treat seams, cracks and joints between sheets. It demonstrates the greatest effectiveness in cases where there is a possibility of displacement of adjacent canvases relative to each other as a result of sudden temperature fluctuations, as well as significant physical activity. Modern manufacturers use siliconized additives that approximate acrylic roofing sealant in properties and characteristics to silicone. At the same time, its cost remains more affordable. Most often, acrylic-based products are used to work with porous substrates, such as brick, concrete - here it demonstrates maximum efficiency.

It can be not only white, but also transparent. Due to antifungal additives, it is possible to protect it from the effects of mold and mildew bacteria and significantly extend its service life.

If you are looking for a sealant for metal roofing, pay attention to the bitumen-based product. In this case, you will get excellent performance and high adhesion to the metal base. Bitumen sealant is represented by bitumen with the addition of aluminum pigment - this is necessary to mask the material on the roof surface. Due to the pigment, the composition acquires a rich metallic tint. This is a truly excellent plastic material, ideal for roofing work. Bitumen sealant has incorporated a number of important properties and characteristics. First of all, it is durability and resistance to various types of influences, including moisture and temperature changes. Moreover, it is really pleasant and convenient to work with, and all thanks to its excellent adhesion not only to dry, but also to wet substrates. Bitumen-based sealant is ideal for filling cracks, joints and voids between metal sheets, as well as the junction of the roof with the ridge and chimney - it not only insulates well, but also fixes individual components.

When working with bitumen sealant, one should take into account its high toxicity, which is why it is suitable exclusively for outdoor work. Do not use any remaining composition inside your living space under any circumstances. To summarize, I would like to note the most pronounced characteristics and properties of this material:

- strength;

- elasticity;

- moisture resistance;

- possibility of painting;

- chemical inertness;

- adhesion to most substrates;

- affordable price.

Polyurethane sealant

The basis of polyurethane sealant is a polymerized resin. By creating special conditions production, observing the temperature regime, it is possible to achieve the required viscosity of the material. This is precisely what allows it to be used for sealing flat roofs. Polyurethane sealant performed well when exposed to low temperatures. There are several varieties of this composition:

- sealing - for working with a dry base;

- waterproofing - for working with a damp base and coming into contact with moisture.

Polyurethane sealant is quite popular among modern builders, and all thanks to a number of characteristics. The latter include:

- chemical inertness;

- resistance to damage and temperature influences;

- possibility of coloring;

- efficiency;

- durability.

Perhaps the only drawback of polyurethane-based sealant is its rather high price. But due to its durability and cost-effectiveness, it is completely justified. Moreover, it is polyurethane-based roofing sealant that is considered universal. And all thanks to its adhesion to most known surfaces: wood, metal, brick, concrete.

Tape sealant

If you are looking for a material that is pleasant to work with and at the same time quite effective, you will certainly like roofing sealant tape. The basis here is butyl rubber, which gives the material unique properties and characteristics. Tape sealants withstand various temperature fluctuations well, as well as exposure to direct sunlight, making them excellent for roofing work. The tapes have high adhesive properties, making it easy to installation work: just apply the product to the junction of the material, press it tightly - and you will get a reliable and durable, and most importantly, hermetically sealed connection.

Metal roof insulation

If you decide to install a metal roof, then the sealant for its insulation must have excellent adhesion to metal surfaces, withstand vibrations and exposure to precipitation. Sealants based on bitumen and polyurethane have these properties. To work with them, you must first degrease the base with an ordinary solvent.

Roof insulation from corrugated sheets

The construction of such a roof involves horizontal and vertical fixation of the roofing material. In this case, acrylic, silicone would be a good choice. Before work, you need to degrease the base and make sure that it is dry - only in this case can you count on high efficiency.

Soft roof insulation

Need sealant for soft roof? Then you should choose varieties based on bitumen. To insulate the joints of a flat roof, it is better to use bitumen sealant for the resulting joints. It gives a strong, durable and quality connection, resistant to temperature fluctuations and all negative weather conditions.

Tytan is the answer of modern manufacturers

Tytan roof sealant is an invention of modern manufacturers building materials. This is a one-component, plastic and viscous composition, which is based on a combination of bitumen and rubber. This is an excellent sealant, characterized by increased adhesion to metal and bitumen bases. It doesn’t matter whether it’s dry or wet - Tytan does not slip off the surface and provides high-quality and durable insulation. It is used for connecting joints of roofing material and repair work.

Two-component sealants

A two-component rubber-based sealant demonstrates maximum efficiency when working with wood, brick, and concrete. It is characterized by plasticity, chemical inertness and durability. This great option for those cases when it is necessary to obtain an even and beautiful seam. The two-component sealant can withstand significant temperature fluctuations and is easy to use.

Features of use

Most often, sealants are sold in 310 ml tubes. To work with them you will need a special “gun”, which can be purchased at any hardware store. With its help, it is possible to use material economically and also obtain a perfectly smooth and durable seam.

It is much more effective to work with a dry and grease-free base. Even if the sealant requires working with a wet base, it is better to avoid this if possible. To work with the composition, you will need special nozzles, with which you will be able to obtain a seam of the required thickness - these, again, can be purchased at a specialized hardware store.

You must work carefully and carefully so as not to overdo it with soft and plastic material. After completing the work, you need to make sure that the composition fits tightly to the base and edges of the roof - this guarantees a reliable and tight connection.

High-quality roof insulation is the key to its durability and reliability. This is why it is so important to regularly inspect the roof and repair loose seams and cracks. And for this you should use only high-quality materials. And it is not at all necessary to resort to the help of professionals - you can handle most of the work yourself.

Defects in metal roofs are usually associated with leaky connections between their individual elements. But due to roof leaks, considerable problems can arise that will disrupt the normal living conditions in the house and, over time, the building envelope may become unusable. For example, leaks in a pitched metal roof can cause rotting of a wooden rafter system.

Types of roofing sealants

The reliability and strength of any roof is given by the use of special sealing pastes. For example, a sealant for a metal roof should have:

- good elasticity;

- excellent adhesion to metal surfaces;

- increased vibration resistance;

- high water-repellent characteristics;

- increased resistance to weather conditions of any type.

Based on the type of transition to the working state, the following types of materials are distinguished:

- uncured, which do not change their qualities after use. This is an excellent solution for sealing joints of various configurations. A non-curing metal roofing sealant that has good adhesion and is weather and water resistant. The operating temperature range while maintaining its properties is 200 degrees, ranging from -60°C to +140°C. Release form: packaged pastes or double-sided sealing tapes. The latter are quite often used to seal any type of seam joints;

- cured, changing their state either as a result of drying, that is, evaporation of the liquid, or a chemical reaction. According to the method of use, they differ from non-curing ones - their components are mixed immediately before the start of insulation work.

No matter how the mixing takes place - manually or using special equipment, the “life activity” of the composition does not exceed three hours.

Manufacturers and products

Choosing a sealant for a metal roof is both easy and difficult. On the one hand, quite wide range, on the other hand, the quality of the material is of particular importance. Considering the disastrous results that using low-quality roofing materials can lead to, it is advisable to first look for them among the products of well-known manufacturers. Let's give just a few examples.

Titan brand sealants can be used at sub-zero temperatures, on surfaces of any orientation, including vertical. There are no restrictions on the composition of the base. High adhesion rates make it possible to do without preliminary preparation of the base. It can be used on metal, tile, wood and other surfaces. For example, Tytan Industry PU-25 is suitable for insulating seam and flat roofs.

Titan brand sealants can be used at sub-zero temperatures, on surfaces of any orientation, including vertical. There are no restrictions on the composition of the base. High adhesion rates make it possible to do without preliminary preparation of the base. It can be used on metal, tile, wood and other surfaces. For example, Tytan Industry PU-25 is suitable for insulating seam and flat roofs.

Sazilast 51–53 is used for seam roofs. Sealing can be carried out at external temperatures ranging from -15°C to +40°C.

Sazilast 51–53 is used for seam roofs. Sealing can be carried out at external temperatures ranging from -15°C to +40°C.

SOUDAL Aquafix adheres to most surfaces, including wet or underwater surfaces. Ideal for emergency repairs or other work in the rain. The product is used for metal tiles and for repairing leaks in gutters. The surface for it must first be  degrease, clean from dust and dirt, the paste itself is ready for use.

degrease, clean from dust and dirt, the paste itself is ready for use.

Silicone sealant Ceresit, manufactured by Henkel Bautechnik, is even more resistant to extreme temperatures. After hardening, it becomes like plastic and is not elastic enough, so it does not deform at the same time as the seam.

How to work with sealant

Today, the silicone type has become especially widespread. Its use is so simple that it allows you to do everything necessary work without the involvement of professionals. As when working with any material, there are also some nuances here. For example, the condition for reliable sealing of seams is the following ratio between its depth and width - it should not be more than two to three.

Today, the silicone type has become especially widespread. Its use is so simple that it allows you to do everything necessary work without the involvement of professionals. As when working with any material, there are also some nuances here. For example, the condition for reliable sealing of seams is the following ratio between its depth and width - it should not be more than two to three.

Usually the depth of the seam turns out to be greater, then to adjust the parameters, a special polyethylene cord is first inserted into it.

Even if you don’t have one ready-made, you can make the cord yourself from ordinary plastic bags or bags.

A large seam width can be “corrected” by placing a strip of polyethylene on three planes.

Before using the sealing composition, the surfaces are carefully prepared: cleaned, degreased, and in some cases additionally primed.

To obtain a smooth surface, use a spatula with a width corresponding to the width of the seam, designed specifically for this purpose, or special leveling mixtures and sprays. It should be noted that the drying time of the silicone sealant is determined by the depth and width of the joint being filled, but, one way or another, very little time is needed for the initial hardening of the viscous mass.

Metal roof sealing technology

The seams and places where the seam fasteners are connected are sealed with polyurethane.

It is prohibited to use silicone materials for seam roofs, as they cause rust to appear on the surface of the seams.

Such work is carried out in stages. First, the surface is cleaned of dirt, including rust, degreased with a solvent and thoroughly dried. Only then is paste applied to the folded seam.

Note that it is not always convenient to use sealant in this form. Sometimes, for example, it is necessary to ensure that the paste adheres to the surface, and not the formation of a convex seam.

Note that it is not always convenient to use sealant in this form. Sometimes, for example, it is necessary to ensure that the paste adheres to the surface, and not the formation of a convex seam.

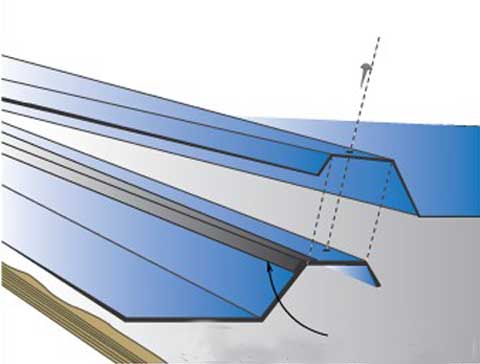

For corrugated roofs, for example, it is sometimes more convenient to use self-adhesive tapes with a sealing compound applied. On one side, remove the anti-adhesive coating and press the tape with the sticky side to the cleaned and grease-free joint of the sheets. If necessary, the edge is rolled with a roller.

For complex surfaces, say, places adjacent to structures facing the roof, special tapes with a corrugated surface are used.

Recently, our company has encountered many requests for repairs of roofs and facades of cottage houses. In all cases, water leaked through the roof and penetrated the walls. The façade was crumbling and falling off. When examining the roof, it turned out that during construction, the sheathing under the roofing sheets was made poorly and the joints of the sheets were not sealed. The service life of such a facade and roof will not be long.

Roof inspections must be carried out annually during the warm season. If you wait until winter, the roof may leak under the pressure of ice. There are winters when not soft snow falls, which is blown away by the wind, but a thick layer of ice forms on the roof. In this case, the seams of the roof separate, and the ice, melting from the heat coming from the attic, melts and floods the building. Water floods walls, computers and furniture. The saddest thing is that it is difficult to repair the roof in winter and people suffer from leaks all winter. It is necessary to carry out roof repairs, facade repairs, repairs and sealing of facade interpanel seams in a timely manner and in a favorable season. In winter, you need to regularly remove snow and ice from the roof. All these building maintenance activities are interconnected. High-quality building maintenance allows for less frequent repair work.

If your roof has leaks, do not rush to replace the rafters, sheathing and roofing iron. Of course, replacing the old roof is the best solution, but leaks can be eliminated with local repairs and sealing of seams and junctions. Destruction of the junctions of the roofing sheet and the facade, junctions and seams of the roof itself are the most common causes of roof leaks.

Sealing of joints, junctions, roof seams.

The roof of any building wears out. They sag and deform under the load of snow and ice. load-bearing structures roofs. Roof seams, joints and joints or folds become deformed and diverge. Before winter, it is necessary to diagnose and repair the roof. All seams of galvanized roofing must be coated with sealing mastic. Sealing the roof seams will protect the roof from moisture penetration and ice will not destroy the roof.

Maintenance of the roof of a building includes winter cleaning of the roof (roof) from snow and ice, and inspection and repair in the summer. Roof maintenance and repair work performed:

The purpose of any type of roof is to provide high-quality protection for the building from adverse weather conditions, and if roof leaks occur during snow melting and heavy rains, then it is necessary to seal the roof seams. In winter, the ice and snow on the roof melt from the heat that comes from the attic, and the top layer of snow presses water into poorly made roof seams. For any type of roof, in winter it is necessary to regularly clean the roof from snow, ice and icicles.

To eliminate leaks in a hard roof, roof seams need to be repaired. By bending the seams or covering with strips of soft roofing and organizing a system for draining water from the roof, leaks can be eliminated, but not for long, because when the temperature changes, the strips crack and the seams separate again.

For quality repairs and long service life of the coating, roof sealing is necessary. The type of repair that is quite economical and gives a long-lasting effect is repair using a sealant that is not destroyed when exposed to ultraviolet rays, does not crack due to temperature changes, fits well on various surfaces and has a long shelf life.

In some cases, when repairing roofs, it is necessary to partially or completely remove the roof deck and high-quality sealing of the roof seams, as well as waterproofing of the junctions with gluing of the joints of the roof with the walls of superstructures, pipes, ventilation shafts and other structures that go onto the roof. In such cases, roof waterproofing is carried out using waterproofing roofing materials.

To draw up a general cost estimate, specialists first examine the condition of the roof covering of a structure or building and determine the optimal methods of sealing the roof to create a high-quality coating with good protective characteristics.

During the cold season, snowfalls and subsequent thaws, which are again replaced by frosts, constantly cause damage to the roof covering, as well as its deformation under the weight of snow, icicles and other ice. This is the main reason for roof leaks. Such leaks occur when the snow begins to melt, and the resulting water, under the pressure of the snow mass, goes inside. Large leaks are real with a meager roof slope, and when the seams have already spread quite widely.

Sometimes they think that if leaks are observed along the entire perimeter of the house, then the water flows along the edge of the roof, but in many cases they occur along the entire seam and the water falls to those places where there is the smallest slope (towards the abutments), where the walls become wet and ceilings. If pitched (metal) roofs are leaking and the leaks cannot be eliminated, then the seams (metal joints on the roof) are made as ordinary standing ones, and such seams can leak as early as next spring after repairs.

To prevent this from happening, it is necessary to seal the roof seams. This is a relatively inexpensive but fairly reliable method of repair. Work technology: First, the previous sealant is removed and the seams that were previously sealed are degreased, then the metal is cleaned from rust and the sheets are secured (if such an action is necessary). Such pre-preparation for working with a new sealant is very important and affects the durability of the repair, so trust it (like other work) only to experienced professionals.

After completing the work on preparing the surface, the abutments, seams, roof joints, all kinds of holes, and any other openings through which water can penetrate into the house (building) are sealed. Similar sealing of roof seams and other cracks is carried out with a conventional (industrial) sealing gun with polyurethane sealant. It should be noted that this sealant has simply excellent adhesion to metal, glass and concrete, and is resistant to almost any temperature changes.

Sealing seams - more details.

In order for the roof not to leak and to serve for a long time and faithfully, it is not enough to lay a high-quality roofing covering. Roof sealing is equally important. It will provide the necessary insulation of all problem areas and protect against moisture penetration. Special roofing sealants are used for roofs.

They are a substance of viscous consistency, based on liquid polysulfide and organosilicon rubber. Sealants perfectly tolerate the most severe temperature changes from -50C to +70C.

What is the role of roof sealing?

Protects joints from moisture.

Provides thermal insulation and waterproofing.

Prevents the formation of cold bridges.

Protects metal elements from corrosion.

Which areas of the roof should be sealed?

Roof sealant must protect the most vulnerable areas, which include:

Places where roofing material overlaps.

In the case of a corrugated roof, the gap between the material and the support beam must be sealed.

Roof joints, chimney, drainage system, ventilation outlets.

Places for attaching roofing materials (insulation, films).

What types of sealants are there?

Today in construction stores you can find compositions that differ in their basis:

Sealant with silicone base. Refers to multifunctional insulating materials. Widely used not only for roofing, but for working with wood and metal. It is highly resistant to temperature changes.

Acrylic sealant. This type is used for caulking joints on walls, floors, and windows. The acrylic base also does an excellent job of smoothing out cracks. The main disadvantage is poor elasticity, due to which the material is not used for outdoor work.

Polyurethane. Excellent sealant for outdoor use. Widely used for sealing joints of wooden, stone, metal elements. In roofing work it is used when minor repairs need to be made.

Bituminous. It is highly toxic, which is why it is used only for outdoor use. Available in different forms. The sealant is resistant to moisture, low and high temperatures, and even chemical compounds.

Which sealant should I choose for metal roofs?

Roofing sealant is used to seal the seams of metal roofing. It is a one-component composition that allows for an elastic connection with sufficient compaction. It should not contain any organic compounds. No silicone or impurities - otherwise rust on the metal will not be long in coming.

The best sealant for metal roofing is a polyurethane-based material. Hardens instantly, even if the work is done on a damp base.

Correct sealing of corrugated roofing

When choosing an insulating material for this type of roof, you need to pay attention to polyurethane roofing sealant. It is he who demonstrates excellent waterproofing properties in practice and is easy to use.

When working with corrugated sheets, you must follow some rules:

When the corrugated roofing sealant has dried, the work is considered completed. Now all problem areas are securely fixed with a dense rubber base that will not allow a drop of water to pass through. The sealing area must be clean and dry.

The material must be applied in an even layer of uniform thickness (about 2-3 mm).

High-quality sealing of roof joints must be carried out.

What is better to choose for metal tiles

A roof made of metal tiles is similar in its properties to a roof made of corrugated sheets. But there are a number of features of its sealing:

Gaps larger than 5 mm are sealed with silicone sealant.

If the roof has an inclination angle of less than 14 degrees, then the longitudinal joints of metal tile sheets are also subject to sealing.

The choice of sealant should also be determined by climatic conditions. In areas with high solar activity, it is recommended to use ultraviolet silicone; you can also use professional gaskets (they repeat the relief of the flooring).

![]()

In conclusion, a few words about such roofing material as flexible tiles. To insulate its seams use modern material as bitumen sealant for roofing. It is based on modified bitumen and organic solvents. It is highly durable and ideal for soft roofing materials.