On the other hand, during this time, science and technology have made a huge step forward, completely new building materials have appeared, but houses made of stone, brick and other blocks continue to be built. At the same time, build not just by eye, and based on the experience of previous generations, but according to long and complex calculations regulated by regulatory documents. Moreover, in almost every project of a house with brick walls 5 floors or more high, horizontal (indirect) reinforcement of the masonry is provided welded mesh. And sometimes horizontal reinforcement is recommended for a 2-3 storey building. Where is the truth? When is masonry reinforcement necessary, and when is it possible to do without it? And in general, what does this reinforcement provide and what kind does it come in?

These questions are especially of interest to people who are not directly involved in design and calculations, but who nevertheless intend to build a small 1-2-story house for personal use. And referring such people to the current regulatory documents is not entirely correct, although it is necessary. Therefore, I will try to answer these questions as simply and concisely as possible (you don’t have to look at the explanations for the answers).

Question: When should masonry be reinforced?

Answer: When calculation or design considerations require it.

I understand that the answer sounds quite vague, so I will try to clarify. As I already said, earlier masonry work was often carried out without reinforcing the masonry, and all sorts of castles and palaces there still delight us with their appearance. The whole point is that aesthetics and reliability used to be highly valued, but they didn’t even know about saving materials, but didn’t give a damn - everything was laid out of stone of approximately the same grade in terms of strength from the nearest quarry. And there was no particular rush, the buildings were built to last and therefore the construction, which lasted for decades, did not particularly frighten anyone.

Now it's a completely different matter. The volume of construction has increased tens, if not hundreds of times, while the construction time has been significantly reduced. Except various types natural and artificial stones now there are also a dozen grades of strength, and there are also a lot of masonry mortars. Thus, when the load on the wall is known, with such a variety, you can always choose a stone and mortar of the appropriate brand to ensure the necessary strength. As a last resort, you can increase the section parameters, in other words, make the wall thicker.

However, such solutions will not always be optimal. For example, a thicker wall will mean an increased load on the foundation, and therefore a recalculation of the foundation. In addition, when building a brick house 16 floors high, selecting bricks and mortar of the appropriate brand for each floor is not a rewarding task, especially if the developer has access to bricks of 2-3 strength grades. And it’s quite difficult to control the quality of work with such variety, not to mention the possible confusion on the construction site when the building is erected unevenly. And sometimes there are strange whims of the architect, which the design engineer needs to fit into.

And then there are design requirements based on many years of experience in construction and design, recorded in various regulatory documents. The convenience of design requirements is that not everything and not always need to be taken into account; moreover, it is quite difficult to take into account all possible influencing factors in the calculations. Therefore, compliance with design requirements will never hurt.

In this regard, the general advice is this: if you are in doubt whether you need masonry reinforcement or not, then it’s better to do it, the safety margin has never hurt anyone.

Question: What types of masonry reinforcement are there?

Answer: Reinforcement can be vertical and horizontal: indirect (mesh) or longitudinal (rods, sheet metal etc.).

Question: When are certain types of reinforcement used?

Answer:

Vertical reinforcement

used to increase the bending strength of masonry. The principle of operation of reinforcement in this case is the same as in reinforced concrete elements, i.e. the reinforcement works in tension, thereby reducing tensile stresses in the masonry. For vertical reinforcement, rolled metal of any profile can be used, the main thing is to securely connect it to the masonry. Technologically, the process of vertical reinforcement is quite complex, moreover, low-rise construction vertical reinforcement of masonry is practically not used, so we will not consider it further.

Horizontal reinforcement with longitudinal bars

It is usually used when laying partitions and walls one block (stone) thick in places where walls meet, in places where internal stresses jump, as well as along the entire length of solid walls (often such reinforcement in the form of a reinforced concrete beam is called an armored belt).

Transverse reinforcement (mesh reinforcement)

It is used for reinforcing masonry walls with a thickness of 2 or more stones (bricks, blocks), as well as for free-standing pillars and piers.

Question: What does longitudinal reinforcement of masonry provide?

Answer: Allows you to increase the local stability of walls at joints, as well as tensile strength when the wall works as a beam.

Increasing local stability allows you to minimize the risk of cracks at the junction of external walls, external and internal load-bearing walls, walls and partitions. Which in turn increases the thermal insulation qualities of the masonry.

For example, external walls under the action of an eccentrically applied load will bend approximately as shown in Figure 250.1.c):

Figure 250.1. Diagrams of internal stresses in cross sections of elements with various geometric parameters.

At the same time, in the places where such perpendicularly located walls meet (in places where bricks or blocks are tied), tangential tensile stresses arise τ (not shown in the picture). And the closer the cross section under consideration is to the middle of the wall height, the greater the tangential tensile stresses. Accordingly, if longitudinal reinforcement is inserted into the masonry every few rows, it will absorb these tangential tensile stresses.

Also, longitudinal reinforcement is used when constructing relatively long solid walls. In this case, the wall is reinforced along its entire length in several rows in height. This allows you to reduce or even completely eliminate the risk of cracks as a result of temperature and shrinkage deformations. And if solid walls more than 50 m long in low-rise construction are very rare, then deformation of walls as a result of settlement of the foundation is a fairly common phenomenon. In such cases, the wall can already be considered as a beam and, accordingly, the reinforcement in the stretched zone of the beam will work in tension.

Instead of reinforcement, metal strips of appropriate thickness and width can be used. In addition, longitudinal reinforcement can be performed in separate reinforced concrete elements - armored belts. Armored belts are usually installed under the floors of each floor (or at the floor level in case of a monolithic floor).

Question: What does mesh reinforcement of masonry provide?

Answer: Reinforcement increases the strength of the masonry.

At first glance, this answer seems stupid. After all, stone, both natural and artificial, is a material that works well under compression. More precisely, the calculated compressive strength of the stone is several times greater than the calculated tensile strength. And with central loading, only compressive stresses should arise in the masonry. And how can reinforcement that works well in tension help, being located in the cross-section of the wall under consideration?

However, not everything is so simple. The linear stress state, even with central compression, is nothing more than a calculation premise that makes it possible to significantly simplify the calculation procedure. In fact, even the cube shown in Fig. 250.1.a), will be in a volumetric stress state. As a result of the load on the cube, not only linear deformation will occur - a decrease in the height of the cube, which is usually taken into account in calculations, but at the same time the length and width of the cube sections under consideration will increase. This happens because any physical body is deformed under the influence of an external load, but still tries to maintain its volume (we are talking about elastic deformations), or rather the distance between atoms and molecules. Even when a blacksmith forges a part, he does not change the volume, but only changes the shape. In turn, this means that in the cube sections under consideration, in addition to normal compressive stresses σ tangential tensile stresses will act T . To absorb these tensile stresses, horizontal reinforcement of the masonry with meshes is used.

Question: Why then is not every row of masonry reinforced, but sometimes every second, every fifth, etc.?

Answer: Because this follows from the calculation of strength.

Let's complete the picture described in the answer to the previous question. A wall made of brick is a composite heterogeneous material consisting of alternating rows of bricks and masonry mortar (we do not consider the quality of masonry and masonry methods, which also affect strength, here at all). And since the modulus of elasticity of brick and masonry mortar are different (and the modulus of elasticity of stone is usually greater than the modulus of elasticity of mortar), tensile shear stresses again arise at the point of contact between stone and mortar. In addition, vertical joints of masonry, as a rule, are filled with masonry mortar worse than horizontal ones, which means that the cross-sectional area of the mortar that absorbs the above tensile stresses is reduced. Mesh reinforcement allows you to minimize the above factors. And the nets, placed in several rows, serve as an additional dressing for the masonry and accordingly increase the strength.

- Principles of work

- Brick wall: transverse type of reinforcement

- Meshes for transverse reinforcement

- Transverse type bar reinforcement

- Longitudinal reinforcement

- Summing up

When constructing any structures, strength characteristics are the most important. Sometimes huge loads act on load-bearing masonry walls and columns, including brick. Requirements for the safe operation of such structures lead to the need to strengthen these structural elements. Reinforced is one of the common ways to increase the strength of buildings.

The technology of structural reinforcement has been developed over centuries. In particular, the question of how to reinforce brickwork was solved by our ancestors. The use of this technique is quite justified for critical structures that are subject to increased strength requirements. In general, reinforced masonry walls, although it complicates the design, fully fulfill its purpose.

Principles of work

Fundamentally, reinforcing structural elements can be located both along the plane of the wall and in the transverse direction (deep into the masonry). The different arrangement of elements is determined by the direction of the load acting on the wall during the operation of the building.

Reinforcement brickwork It is made using wire reinforcement, while the brickwork is significantly strengthened.

The reinforcement, evenly installed on the wall, redistributes the load, preventing local overloads. In addition, by taking on the load, it eliminates the insufficient strength and fragility of the brick and binder. Accordingly, the brick increases its load-bearing capacity.

Depending on the direction of placement of reinforcement, reinforcement is divided into transverse and longitudinal types. In turn, the longitudinal is divided according to the type of placement of the element on the surface of the wall into vertical and horizontal.

In order to do the laying yourself, you will need:

- knitting wire;

- metal corner;

- metal strips;

- mesh for masonry;

- reinforcing bars;

- steel rods;

- metal paint.

Return to contents

Brick wall: transverse type of reinforcement

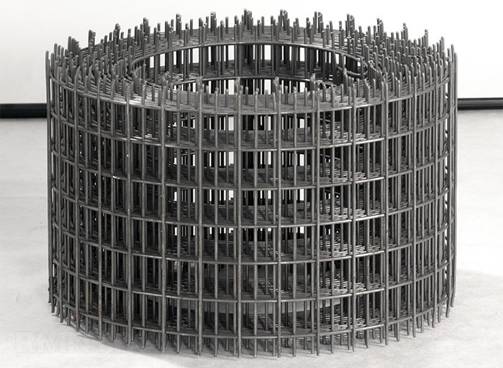

Transverse reinforcement is carried out by applying reinforcing elements to the surface of brick layers to increase its compressive and flexural strength. This type is of particular importance in the manufacture of inclined masonry, for example, an arched type. Special reinforcement (rods) or steel reinforcing mesh can be used as fastening parts. It is allowed to use both standard, factory-made ones and those welded from wire directly during the construction process.

Transverse reinforcement is performed when laying columns and partitions. Reinforcing elements, depending on their design, are laid through a certain number of layers of brick and covered with an additional layer of mortar at least 2 mm thick. For reliable protection from steel corrosion and ensuring the necessary binding properties, the total layer thickness should reach 14-15 mm. One of the types of reinforcing elements is used for the work; using both rods and mesh in one structure at the same time is undesirable.

Return to contents

Meshes for transverse reinforcement

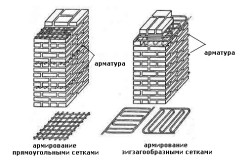

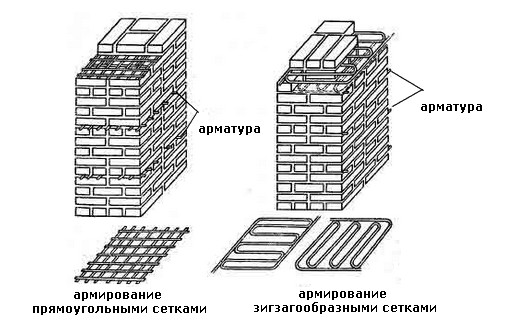

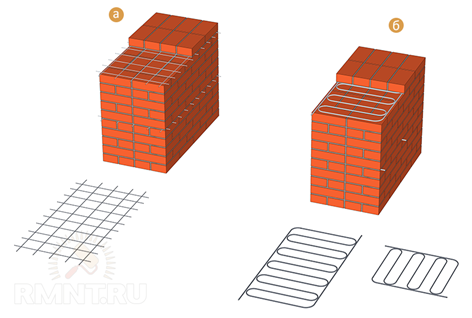

It is customary to reinforce brickwork in the transverse direction with a network or rods. The most common are mesh elements, which, based on the shape of the cell, can be divided into square, rectangular, and zigzag.

Rectangular (square) options are made from steel reinforcement (wire) with a diameter of up to 5 mm. The side size of the cell, depending on the diameter of the reinforcement and purpose, ranges from 30 to 100 mm. Typically, such a grid is laid every five layers of brick. When using thickened bricks, the mesh is applied every four layers. The mesh is applied so that the ends of the wire extend outward on the inside of the wall to a length of 2-3 mm. Bringing the ends out allows you to control the presence of the mesh on the desired layers of masonry. Subsequently, such allowances are sealed with plaster or trimmed.

Zigzag mesh is made of steel reinforcement (wire), pre-curved in the form of a zigzag every 50-100 mm, depending on the diameter of the reinforcement. The cell side size ranges from 50 to 120 mm. Reinforcement is used with a diameter of 5-8 mm. It is customary to lay such material every two layers of brick in pairs with the condition that the direction of the reinforcement in adjacent layers is mutually perpendicular.

Among the modern types of standard mesh, we can distinguish all-metal expanded or drawn mesh, which is used instead of zigzag and is increasingly used. This material is convenient for work and has increased strength characteristics.

Return to contents

Transverse type bar reinforcement

For rod reinforcement, straight or zigzag steel reinforcement is used. Zigzag rod elements are made similarly to mesh, that is, with a zigzag curvature every 50-100 mm in length. The rods are laid through 3-5 layers of brick.

Straight rods are used in regular brickwork. Several rods are placed along the width at a distance of 30-120 mm from each other. The reinforcement is located in the transverse direction and pressed into the seam between the bricks to a depth of 20 mm. Reinforcement with straight rods is carried out every 2-3 rows of bricks. The diameter of such reinforcement is selected within 3-8 mm, depending on the thickness of the seam between the bricks.

In cases where it is necessary to ensure increased strength of the brickwork, instead of round rods, a steel strip or non-circular steel reinforcement can be used. The size of such elements is selected based on masonry parameters and strength requirements.

The construction of buildings or structures requires mandatory compliance with all building codes and regulations. Many of them relate to the strength indicators of elements of buildings and structures under construction.

Currently, many technologies have been developed to help increase the strength of almost all structural elements of buildings.

Didn't stand aside either. Many will say that there is nothing stronger and better than good mortar or concrete, but this is not true. Brickwork can be even stronger if certain elements are added to its design.

It can be reinforced.

Types of reinforcement

Reinforcement of brickwork can be:

- transverse;

- vertical;

- longitudinal.

For transverse reinforcement, individual rods or steel mesh are used. Steel rods prevent tensile and bending deformations.

The rods are connected into a mesh by welding or knitting wire. The connection is made in increments of 30-120 mm. In adjacent seams, instead of meshes, it is unacceptable to lay individual rods perpendicularly.

Mesh made from reinforcement large diameter, leads to a decrease in strength, increasing the thickness of horizontal seams.

Reinforcement of walls, pillars and piers is made with welded masonry mesh, which can have a zigzag, rectangular or square shape.

To prevent the corrosion process, the metal mesh must be recessed into the solution by at least 2 mm on each side. The minimum seam thickness will be approximately 14 mm, including about 5 mm for the mesh.

The mesh is laid in every fifth row of masonry. If the brick is larger standard size, then you need to reinforce with a rectangular mesh in every fourth row.

The production of zigzag reinforcement is carried out only at the construction site. It all looks like wire rod with a diameter of 5-15 mm, bent every 5-10 cm. It cannot be reinforced with large-diameter zigzag wire, since the seam will be too wide.

Laying of zigzag reinforcement is also carried out every fifth row. It is laid in pairs and at right angles to the two previous rows. This method of reinforcing masonry is quite simple, and the consumption cash will be minimal. Well suited for private homes. The laying of lintels and other similar elements is carried out together with transverse reinforcement, which has the form of straight rods.

Reinforced brickwork walls

In seismically active areas, the walls of structures are strengthened using vertical and longitudinal reinforcement methods. This reinforcement is used to absorb tensile deformations during the construction of thin walls, pillars and partitions.

The meshes are placed with a projection beyond the inner surface of the wall by 2-3 mm. This serves as a kind of guide for the location of reinforcement in the masonry.

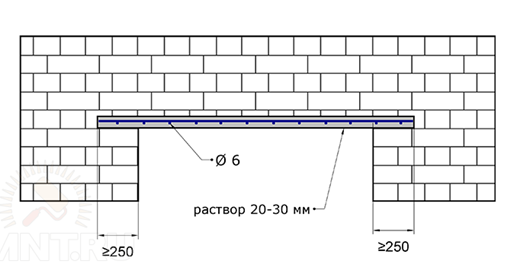

The longitudinal method of reinforcing a brick wall can be done with class AI and AII reinforcement. In this case, the amount of solution (thickness) will directly depend on the humidity level. At moderate humidity, the layer thickness does not exceed 10-12 mm. High humidity requires laying on a layer of mortar having a thickness of 20-30 mm.

To reinforce brickwork walls in vertical planes, class AI and VI reinforcement with a diameter of 3-8 mm is used.

There is also an alternative to reinforcing mesh - a modern reinforcing material called TsPVS mesh. With high levels of strength and reliability, such meshes are much lighter than reinforcement meshes and more convenient to install.

In ordinary masonry, the wall is often reinforced with straight reinforcement. Several reinforcement bars are laid along the width of the wall and implanted 15-20 cm into the masonry, thereby strengthening the lintel and evenly distributing the loads exerted by the brick on the opening. The wire is laid every 2-3 rows, depending on the pressure exerted on the lintel. The diameter of direct reinforcement depends on the masonry joint (its thickness). You need to know that the opening or lintel should not exceed 2 m in length.

Reinforcement of brick pillars

Laying pillars has two options:

- under load-bearing structures. The function of the pillars is a support that can withstand loads with a small base area of the pillar resting on the foundation. Such pillars are subject to only vertical loads;

- fence posts. The designs of such pillars are divided into two types: for gates and wickets and as separate sections.

Reinforcing brickwork is a fairly simple process, but it is mandatory. Reinforcement does not require any special knowledge, but plays a vital role in the durability and reliability of the structure. To avoid mistakes and avoid further problems, it is better to seek advice from specialists. The cost of this is minimal compared to the possible costs of restoring the wall. When selecting reinforcement, it is necessary to take into account all the nuances and subtleties of its purpose and comply with all norms and rules related to reinforcement.

The strength of brickwork can be increased by reinforcement. The reinforcement placed in the seam allows the load to be distributed over its area. Reinforcement of pillars, partitions, pilasters and other brick structures must be carried out in compliance with regulatory rules. This will guarantee the quality of construction.

Types of reinforcement

The type of reinforcement in brickwork depends on the forces acting on the structure. When the load acts centrally or with a slight deviation from the center of the structure section, transverse (mesh) reinforcement is recommended.

If the load is applied with a sufficiently large shift from the center (eccentricity), then longitudinal reinforcement is necessary. It will ensure the strength of the structure from bending and stretching.

Transverse reinforcement

For transverse (mesh) reinforcement, two types of mesh are used: with rectangular cells of the “zigzag” type. They are laid on a mortar bed in the masonry seam. The distance between rectangular grids is allowed no more than 0.4 m in height. This is approximately five rows of masonry.

a - reinforcement with rectangular meshes; b - reinforcement with zigzag mesh

Zigzag meshes are installed in two adjacent horizontal rows mutually perpendicular to each other. Transverse reinforcement is carried out with the ends of the mesh moved beyond the surface of the masonry by 5 mm in order to control the reinforcement of the structure.

The thickness of the seam is taken to be 4 mm greater than the diameter of the reinforcement used. For reinforced masonry structures, the grade of mortar is taken to be no lower than 50. The percentage of reinforcement in brickwork by volume determines the amount of reinforcement in it:

· μ = V a / V k x 100

For grids with rectangular cells:

· μ = 2f a / cs

Where:

· f a - reinforcement section;

c - cell size;

· s is the height distance between the grids.

For reinforced masonry structures, calculations are made for large loads; for small loads, reinforcement is installed structurally (according to recommendations). The reinforcement percentage (μ) should be between 0.1 and 1%.

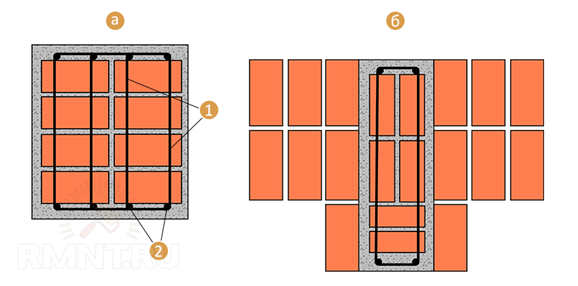

Longitudinal reinforcement

Longitudinal reinforcement takes on the tensile and bending forces that arise in the brickwork. If their values are large, a mandatory calculation is performed. Structurally, such reinforcement is used for thin walls and partitions, high pillars for stability, and also if the structure is subject to vibration.

a - external longitudinal reinforcement; b - external reinforcement in the groove; 1 - clamps; 2 - longitudinal reinforcement

For longitudinal reinforcement, reinforcement is laid both inside and outside the masonry. For the internal placement of reinforcement, grooves are made in the masonry, external reinforcement is made in a layer of mortar, the grade of which is allowed to be no lower than 50, and the grade of brick is not lower than 75.

The longitudinally installed reinforcement is connected to each other with clamps. For external reinforcement, clamps are laid at a distance of no more than:

· 15 rod diameters in a compressible structure (2–3 rows of masonry);

· 80 rod diameters in stretched design (maximum 50 cm).

When the reinforcement is located internally, the clamps are installed at least at a distance equal to 25 diameters of the longitudinal rod.

The protective layer of reinforcement for rooms with normal operation is 10–12 mm. For wet and damp rooms it is increased to 30 mm. The protective layer for clamps is 10 mm.

The pitch between longitudinal rods in walls and partitions should be no more than 8h, where h is the thickness of the wall. The percentage of longitudinal reinforcement in bars compressed under load is allowed less than 0.1%, in tension bars - 0.05%.

Armature

For transverse reinforcement they are mainly used metal mesh from cold drawn wire V-1, VR-1 (V500) with a diameter of more than 3 mm. Round reinforcement made of steel class AI (A240) with a diameter of at least 6 mm is also used in meshes, if the rods intersect at the masonry seams, if not, then at least 8 mm.

The wires and rods in the meshes are welded or tied with wire. For rectangular meshes, the mesh size is 3–12 cm. Zigzag meshes are made from wire with a diameter of more than 5 mm.

The diameter of the longitudinal reinforcement is:

· more than 3 mm for clamps and stretched rods;

· more than 8 mm for compressed rods.

Rods of class AI (A240), AII (A300) are used as structural longitudinal reinforcement. In most cases, the amount of reinforcement is calculated.

Modern industry building materials produces polymer composite reinforcement, including composite reinforcing mesh. This is a lightweight, high-strength, corrosion-resistant and cheaper material. In many respects, composite reinforcement is superior to metal reinforcement.

For reinforcement, the diameter of composite reinforcement is taken to be smaller than that of steel:

· Ø 6 mm steel - Ø 4 mm composite;

· Ø 10 mm steel - Ø 6 mm composite;

· Ø 12 mm steel - Ø 8 mm composite.

Features of reinforcement of brick building structures

Transverse reinforcement can be used when it is impossible to increase the grade of brick or mortar to ensure the required strength of the masonry.

Partitions made of 1/4 bricks, in order to increase stability, are reinforced with a steel strip of 1.5–2.5 mm or rod reinforcement with a diameter of less than 6 mm every 6 rows of masonry. When the thickness of the partitions is 1/2 brick and its length is more than 3 m, reinforcement is placed in the horizontal seams every 5–6 rows. In this case, the ends of the reinforcement must be embedded in the main walls.

Sometimes partitions or interior walls are being built in different times with external walls (pillars) mating with them. In this case, rod reinforcement with a minimum diameter of 6 mm is laid into the structure of the main wall or pillar.

Subsequently, it is embedded in the masonry joints of the partition. The height distance between the rods is allowed to be no more than 2 meters. The same rods are laid at the floor level. The length of reinforcement embedded in walls and partitions is assumed to be a maximum of 1 m.

The fittings are also used for the installation of ordinary jumpers in brick walls. In this case, high-quality filling of all seams is necessary. The height of the lintel is 5–6 rows of masonry, the length is 50 cm on each side of the opening + the width of the opening.

The construction of the lintel begins with the laying of reinforcing bars with a diameter of 5–6 mm or a steel strip. There should be one rod for every half brick. To the side of the opening, the reinforcement is embedded into the masonry to a minimum of 25 cm.

When docking reinforcing mesh the amount of overlap is from 15 cm. The choice of brick affects the distance between the grids and is:

· less than 5 rows for ordinary clay bricks;

· less than 4 rows for thickened bricks;

· less than 3 rows for ceramic stone.

Structural (without calculation) reinforcement with meshes, which are laid less frequently than every 45 cm in height, prevents destruction and delamination of the masonry.

Reinforcement of free-standing pillars can be done using a metal clip, reinforcing bars, combining them with clamps and a protective layer of concrete or mortar.

a - metal clip; b - reinforced concrete frame; c - reinforced plaster; 1 - metal strip 35x5–60x12; 2 - welding; 3 - rod reinforcement Ø 5–12 mm; 4 - clamps Ø 4–10 mm; 5 - concrete B7.5–B15; 6 - solution grade 50–100

The reinforcement embedded in the brickwork allows the entire structure to work like a monolith. This increases the strength, stability, durability and reliability of the entire building or structure.

http://www. rmnt. ru/ - RMNT website. ru

The appearance of cracks in brick buildings is not uncommon; according to statistics, this occurs in a third of newly built houses. The causes of cracks can be:

- mistakes made during the design process;

- uneven settlement of the soil base;

- violations of construction technology;

- seismicity of the construction area;

- significant increase in loads, etc.

The simplest and most widely used method for increasing the strength of a structure is reinforcing brick masonry.

In what main cases is reinforcement necessary?

- Existing heavy loads on building envelopes. For example, in multi-storey buildings underlying structures are affected by weight upper floors(walls and partitions, floor slabs, flights of stairs and landings, roof, finishing materials, furniture and people);

- When constructing buildings on subsiding and heaving soils, there is a high probability of cracks appearing in the walls.

- The construction area is located in a seismic zone. To absorb the effects of tremors, it is necessary to ensure increased strength of the structures.

- Construction of brick arches and free-standing columns.

- Complex masonry forms.

- Use of low quality building materials (low grade bricks, chipped, large number half products, low grade solutions).

The correct reinforcement of brickwork is set out in SNiP, the provisions of which are mandatory. If you carry out the work yourself and lack sufficient experience, it is recommended to consult a designer or qualified builder. Such services will not cost much, but incorrect or insufficient reinforcement can lead to expensive costs to correct the deficiencies.

Types of execution

When constructing brick buildings, the following types of reinforcement are used to strengthen walls and partitions:

- factory-made galvanized metal masonry. Available in square, rectangular or zigzag shapes from hot-rolled smooth reinforcement steel A-I and BP-I with diameters of 3...8 mm with cells from 3 to 12 cm;

- reinforcement bars connected with tying wire with a diameter of 5 to 8 mm. When using black rods, careful anti-corrosion painting is required;

- all-metal expanded metal mesh (CPVS), these are modern reinforcing products, manufactured in the factory using expanded metal technologies and have specific gravity 2.5 less than traditional welded ones. The undoubted advantage is high strength, reliability and ease of installation;

- polyethylene and PVC mesh;

- composite and basalt. Products with low weight are not subject to corrosion and rotting, do not carry out electric current, are characterized by high heat resistance and low thermal conductivity. The use of such products makes it possible to reduce the thickness of the seams due to the possibility of reducing the cross-section of the elements. This saves money.

Longitudinal. Often used to reinforce brick partitions and main load-bearing walls to increase their flexural strength and resist lateral forces. Used fittings A-I and A-II with diameters up to 12 mm. It can be internal, for which purpose reinforcing bars (less often mesh) welded together with transverse reinforcement are placed in grooves made in the longitudinal seams in the mortar. Or externally, under a layer of cement mortar. The spacing of clamps for external reinforcement is taken to be ≤ 15 diameters of the reinforcement used, and for internal reinforcement 25 diameters. The strength of the walls directly depends on compliance with these conditions. Often, in non-load-bearing partitions made of half a brick, basalt mesh is laid in every 5th row. In the same way, reinforcement of facing brickwork can be carried out for connection with load-bearing walls.

To strengthen thin partitions, steel corners connected to each other by metal bridges are also used to insert steel corners into the seams on both sides. Corners can be laid only on one side. Vertical rods or mesh are attached to the corners and then covered with plastering. cement mortar.

Vertical reinforcement of brickwork. Often, brick columns are reinforced in this way, in which it is impossible to place reinforcement in the internal cavity or it is impossible to increase its size to perform external reinforcement. In this case, steel corners are installed in the corners of the column or pillar design section, united by welding metal transverse bridges. This operation not only strengthens the masonry, but also partially absorbs the loads acting on the structure. For vertical reinforcement of walls, reinforcing bars are placed inside the voids in the brick and then filled with cement mortar. To do this, there must be voids in the masonry running through several rows.

Rod diameters classes A-I, A -II, BI are usually taken from 10 to 16 mm, but in high-rise buildings it can increase to 30 mm or more. Especially vertical laying of reinforcement is necessary in areas with high seismic activity.

Transverse. The brickwork is reinforced with a mesh placed in horizontal joints. The following types of meshes are used:

Nets are not laid in every row. How many rows the brickwork is reinforced is determined by the calculation set out in the building codes. In this case, the magnitude of the loads acting on the wall, their displacement from the central axes and the height of each row are taken into account. Most often, grids are laid at intervals of 2 to 5 rows, and when using thickened bricks, no more than 4. Zigzag ones are laid in two adjacent rows in pairs, so that the arrangement of the rods in them is mutually perpendicular.

The effect of using meshes is reduced when they are located at a distance of ≥ 45 cm. Structurally, the products are located at intervals of ≤ 1 m. Installation is carried out with an overlap of ≥ 15 cm. The layer of mortar at the bottom and top should be ≥ 2 mm. From inner surface the ends of the mesh should protrude at least 2 - 3 mm. This makes their location accessible for visual verification of correct installation and serves to strengthen the connection with internal lining. If necessary, the ends can be easily cut off with metal scissors.

Reinforcement of masonry with nets is carried out in combination with a solution ≥ M 50.

Mandatory rules

- Reinforcement of load-bearing walls should be done from the very bottom. If the base is brick, then it also needs to be strengthened.

- In window openings, the fittings are laid in 2 rows under and above the opening, in door openings - in two rows above the lintel.

- Differences in height (for example, when connecting a part under construction to an already constructed building) are connected by reinforced belts.

- With internal reinforcement, the reinforcement is completely recessed into the solution.

- The thickness of the seams should be at least 4 mm greater than the cross-section of the reinforcement.

- To reinforce walls, reinforcement with the same characteristics and the same cross-section should be used. The reinforcement spacing on the wall must be fixed.

- For loads of the same sign, single longitudinal rods are laid on the stretched side of the walls; for loads of alternating sign, on both sides.

- The ends of the reinforcing bars are embedded in adjacent stable structures.

Proper reinforcement helps uniform distribution loads, will significantly increase the strength characteristics of the structure and significantly increase its durability.