![]()

In conditions of great competition, we, the manufacturers of all-metal expanded metal mesh TsPVS, are the flagship of the services provided and best prices for our Buyers.

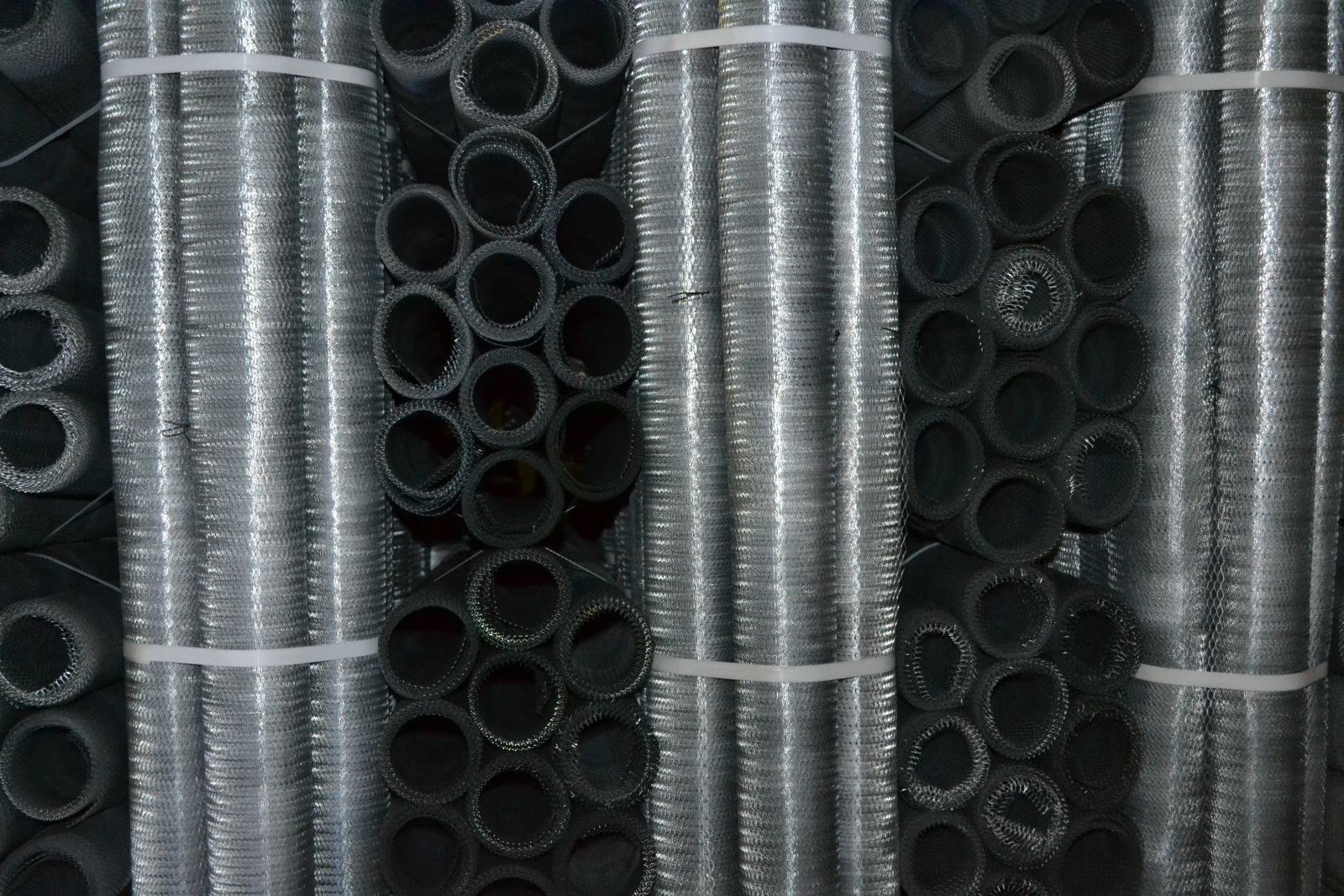

| Expanded mesh in rolls (CPVS) | ||||

| Sheet thickness, mm. | Cell size, mm. | Roll size m. | Black Price per m 2. | OTs Price per m2. |

| 0,5 | 15 x 5 | 1x4 | 34,00 | 40,50 |

| 40 x 10 | 1x7 | 13,00 | 15,50 | |

| 40 x 15 | 1x10 | 13,50 | 17,00 | |

| 40 x 17 | 1x7 | 26,00 | 31,00 | |

| 40 x 20 | 1x10 | 54,00 | 65,00 | |

| 25 x 10 | 1x10 | 27,00 | 32,50 | |

| 40x40 | 1x10 | 26,00 | 32,50 | |

All-metal expanded metal mesh

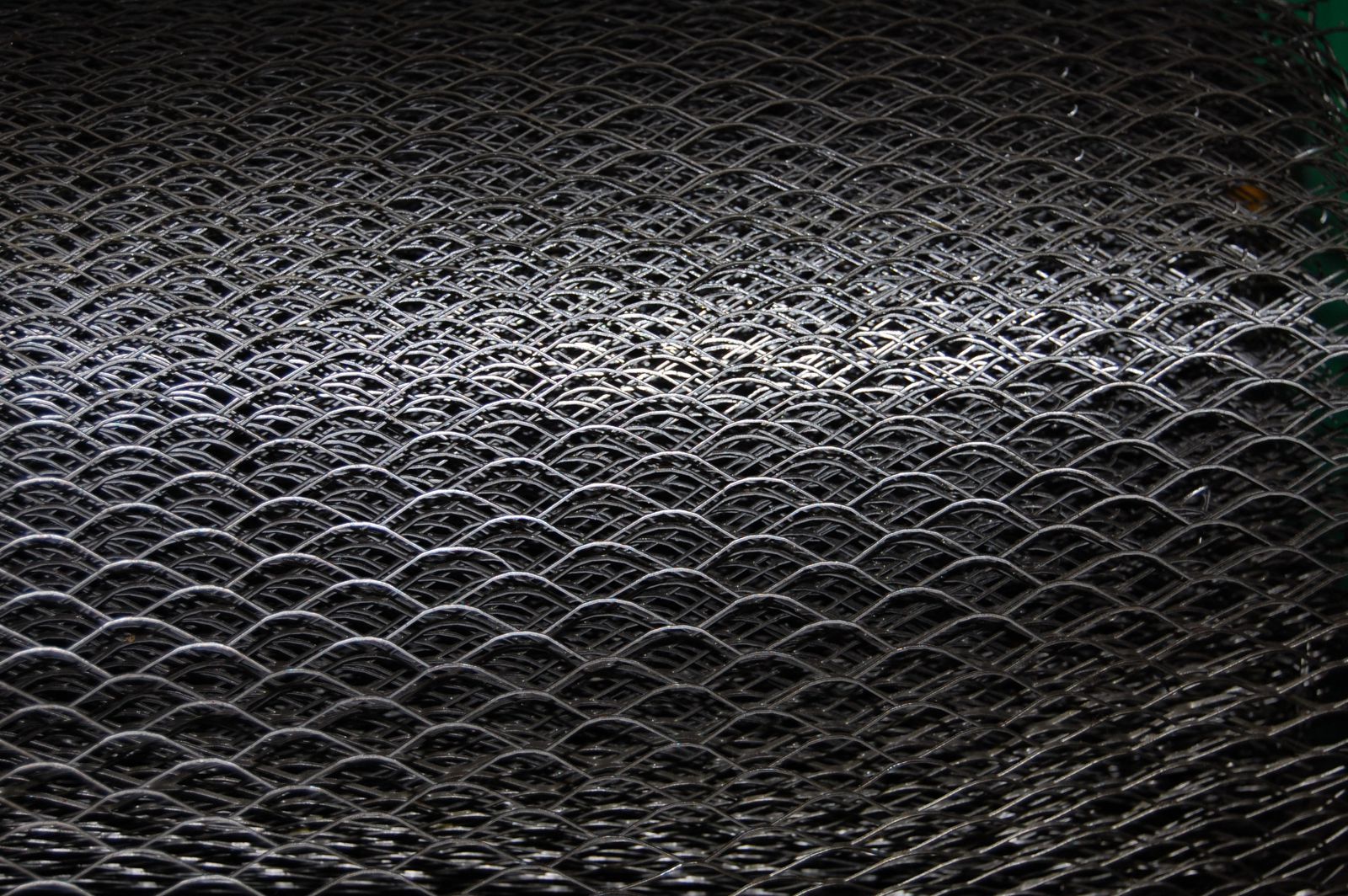

TsPVS galvanized or plaster mesh is made from all-metal thin sheet steel (non-galvanized or galvanized) in accordance with GOST 16523-89 with a sheet thickness from 0.5 mm to 1.2 mm, by simultaneously cutting and drawing the galvanized mesh, which provides the cutting with a good ratio of strength and weight. With this production of expanded mesh for plaster, the loss of the starting material and the formation of production waste are almost completely eliminated. The cells are obtained in one piece, without weaving or welding. Expanded metal mesh has a beautiful appearance and is a modern alternative to the usual and outdated types of metal mesh.

TsPVS galvanized or plaster mesh is made from all-metal thin sheet steel (non-galvanized or galvanized) in accordance with GOST 16523-89 with a sheet thickness from 0.5 mm to 1.2 mm, by simultaneously cutting and drawing the galvanized mesh, which provides the cutting with a good ratio of strength and weight. With this production of expanded mesh for plaster, the loss of the starting material and the formation of production waste are almost completely eliminated. The cells are obtained in one piece, without weaving or welding. Expanded metal mesh has a beautiful appearance and is a modern alternative to the usual and outdated types of metal mesh.

- Distinctive properties of expanded metal mesh:

- Ease. It is two times lighter than welded and woven mesh;

- Transparency. It has a transparent structure that allows the passage of light, sound, air, and liquid in the required volume;

- Flexibility. Seamless smooth design allows the mesh to take on almost any surface shape;

- Structural integrity. The all-metal texture eliminates the possibility of unraveling, and disruption or damage to individual elements does not affect the integrity and strength of the entire canvas;

- High strength properties. Withstands loads of over 2 tons. When reinforced, expanded metal mesh prevents cracks on the surface due to fluctuations in humidity, temperature and mechanical stress. Also, TsPVS is a certain insurance that ensures the strength of the plaster in the event of incorrect preparation of building compositions;

- Ultra-strong adhesion to the surface thanks to the natural three-dimensional structure.

- Due to its excellent properties, it has a very wide range of applications:

- Finishing works,

- The use of TsPVS mesh in the construction of heat and noise insulation facade systems,

- Used for thermal insulation of pipes,

- Reinforcement of any surfaces with TsPVS mesh (walls, ceilings, final floors, tiling work and natural stone),

- Interior design,

- Application in fencing for garden areas, electromechanical devices etc.,

- Use in filters for cars and trucks,

- Application in screens for radiators and ventilation grilles,

- Manufacturing of cages and pens for domestic animals,

- Floorings on surfaces with different properties (flights of stairs, soil, etc.).

Also, the TsPVS mesh is used in the form of flooring for construction sites. For industrial purposes, such a mesh can be used for making containers and sifting crushed rock. Exhaust mesh found great application as a means of protection - for a variety of fencing of garden and courtyard areas, windows, balconies, gazebos, verandas, entrances to basements and attics.

It is a manufacturer of all-metal expanded metal mesh and offers its customers to buy TsPVS mesh wholesale or retail at a favorable price. By purchasing expanded metal mesh (ECM) from us in Moscow and the Moscow region, you are making the right and cost-effective choice!

Ventilation grilles are an important element of the air exchange system in the house. In addition to decorative, they perform a regulatory function, dispersing directional air flows and regulating them throughput. The gratings are made from various materials, but most often galvanized sheet steel and durable plastic are used for this.

By design features ventilation grilles are adjustable, non-adjustable and inertial. Depending on the place of installation, they are divided into external, internal and transfer.

Grilles for outdoor installation

External ventilation grilles are installed on the walls of houses on the street side to protect against dirt, leaves, rain or snow. They are made of sheet steel and are often equipped with a metal mesh to protect against small rodents and insects entering the house. To protect against cold air getting inside winter time ventilation grilles are used check valve, which allow air flow in only one direction.

Grilles for indoor installation

Plastic or metal ventilation grilles are installed inside the building to decorate air duct openings. They can be equipped with movable blinds or deflectors to disperse the air flow. Internal grilles are small in size and have a neat, often decorative appearance.

Transfer ventilation grilles

They serve to ensure air exchange between rooms and are sometimes installed in. In order to maintain light and sound insulation of the room, the grille blinds are V-shaped.

Ventilation grilles in the Leroy Merlin store

In the store's assortment " Leroy Merlin» there are external and internal ventilation grilles made of metal and plastic. A variety of shapes, sizes and colors makes it possible to choose products for any need: not only to ensure sufficient air exchange in the house, but also to successfully fit them into the interior of living rooms.

| Mesh TsPVS "Shtrek" without coating for plastering work in a roll | ||||||

|---|---|---|---|---|---|---|

| Name | Code | Weight, kg | Unit change | Wholesale price | Retail price | Order |

| Mesh TsPVS "Shtrek" without coating 10-C 20x10x0.7; 1x10 | Ф0100147 | m2 | 47.78 | 52.56 | ||

| Mesh TsPVS "Shtrek" without coating 20-C 40x18x0.7; 1x15 | Ф0100149 | m2 | 24.56 | 27.02 | ||

| Mesh TsPVS "Shtrek" without coating 30-C 60x30x0.7; 1x20 | Ф0100150 | m2 | 13.73 | 15.10 | ||

| Mesh TsPVS "Shtrek" galvanized for plastering work in a roll | ||||||

|---|---|---|---|---|---|---|

| Name | Code | Weight, kg | Unit change | Wholesale price | Retail price | Order |

| Mesh TsPVS "Shtrek" galvanized 10-Zn 20x10x0.7; 1x10 | Ф0100151 | m2 | 65.46 | 72.01 | ||

| Mesh TsPVS "Shtrek" galvanized 20-Zn 40x18x0.7; 1x15 | Ф0100152 | m2 | 29.25 | 32.18 | ||

| Mesh TsPVS "Shtrek" galvanized 30-Zn 60x30x0.7; 1x20 | Ф0100153 | m2 | 21.00 | 23.10 | ||

| Mesh TsPVS "Shtrek" galvanized rigid for plastering work in a roll | ||||||

|---|---|---|---|---|---|---|

| Name | Code | Weight, kg | Unit change | Wholesale price | Retail price | Order |

| Mesh TsPVS "Shtrek" galvanized rigid 10-Zn H 20x10x1.5; 1x5 | Ф0100154 | m2 | 128.94 | 141.83 | ||

| Mesh TsPVS "Shtrek" galvanized rigid 20-Zn H 40x18x1.5; 1x10 | Ф0100155 | m2 | 64.48 | 70.93 | ||

| Mesh TsPVS "Shtrek" galvanized rigid 30-Zn H 60x30x1.5; 1x15 | Ф0100156 | m2 | 45.28 | 49.81 | ||

| Mesh TsPVS "Shtrek" for reinforcement without coating in cards | ||||||

|---|---|---|---|---|---|---|

| Name | Code | Weight, kg | Unit change | Wholesale price | Retail price | Order |

| Mesh TsPVS "Shtrek" without coating 50-C 100x50x2; 0.5x2 | Ф0100157 | m2 | 110.00 | 121.00 | ||

| Mesh TsPVS "Shtrek" without coating 50-C 100x50x2; 1x2 | Ф0100158 | m2 | 110.00 | 121.00 | ||

| Mesh TsPVS "Shtrek" without coating 100-C 200x100x2; 0.5x2 | Ф0100170 | m2 | 80.00 | 88.00 | ||

| Mesh TsPVS "Shtrek" galvanized for masonry work in a roll | ||||||

|---|---|---|---|---|---|---|

| Name | Code | Weight, kg | Unit change | Wholesale price | Retail price | Order |

| Mesh TsPVS "Shtrek" galvanized 15-Zn W 25x15x1.5; 0.09x20 | Ф0100161 | m2 | 126.38 | 139.02 | ||

| Mesh TsPVS "Shtrek" galvanized 15-Zn W 25x15x1.5; 0.18x20 | Ф0100160 | m2 | 120.70 | 132.77 | ||

| Mesh TsPVS "Shtrek" galvanized 15-Zn W 25x15x1.5; 0.3x20 | Ф0100171 | m2 | 115.02 | 126.52 | ||

Call now!

Receive detailed information on the range of TsPVS metal mesh, special conditions or you can place an order with our specialists.

Usage modern technologies and innovation in the construction industry is a justified and reasonable decision. TsPVS SHTREK mesh is one of the everyday materials of the new generation: this option is economical and is considered more popular among construction professionals. It is a successful replacement for standard metal mesh used in the construction and finishing of various buildings and structures.

Product Specifications

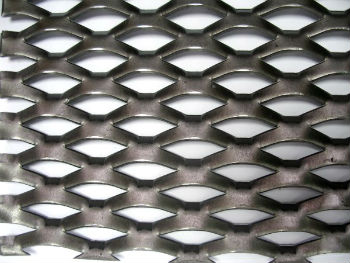

TsPVS STREK - a sheet of rolled metal with cells cut evenly and elongated in the longitudinal direction. Obtaining such a structure corresponds to the geometry of the cutting knives; the cells are arranged in a checkerboard pattern.

In the manufacture of metal gate mesh, cold-drawn steel sheets b = 0.5-2.0 mm grades 08, 08ps, 08kp, stainless steel are used; ordinary quality steels can be coated with zinc or powder polymer (PPP).

Regulatory and technical documentation and TU 1275-001-80025273-2007 regulate the main geometric dimensions of the plaster mesh TsPVS:

- cell length 6-75 mm;

- rib width 0.15-9 mm;

- rib thickness 0.15-3 mm.

By agreement with the consumer, it is possible to manufacture and supply material with the required parameters in Moscow.

Features of production technology

The use of special equipment for the manufacture of plaster drift mesh makes it possible to transform sheet metal by performing the operations of cutting and drawing into a sheet with diamond-shaped cells. The part of the metal located between the cells helps to increase the strength of the resulting material.

The production process is carried out practically without waste, which makes it possible to reduce the cost of materials and reduce the price finished products compared with similar products - chain-link mesh and welded mesh made of wire.

The plaster galvanized mesh TsPVS STREK is easier to process, cut and cut, with equivalent quality characteristics specific gravity she has less.

Distinguished by aesthetics appearance, galvanized mesh has a solid structure along the entire length of the web, which improves the quality of reinforcement or fencing.

Changing one of the main parameters of the product (thickness and feed pitch of the sheet, mesh size) with other constant values allows you to obtain an updated version of the plaster mesh in terms of the level of rigidity and the amount of exhaust.

Application of TsPVS STREK mesh

The “Setka77” company offers wholesale and retail purchase of drift mesh, characterized by high quality indicators and manufacturability.

The products are popular and in demand during construction work and using various surfaces as a reinforcing element to perform plastering work:

- for reinforcing and restoring coatings various types;

- when reinforcing walls for painting;

- to strengthen brickwork and blocks;

- when laying floor tiles and industrial floors;

- for fastening roofing insulation and additional roof protection;

- for fastening insulation when carrying out finishing works facade;

- when doing masonry brick wall;

- for reinforcement when pouring foundations;

- for fastening thermal insulation during installation of heating mains;

- for surface reinforcement during laying facing stone;

- in the manufacture of ventilation grilles.

Galvanized metal mesh TsPVS (roadway) is quite often used in the construction of various enclosures, site fencing, gazebos, verandas, stair steps, etc. In the industrial sector, this material is used in the production of containers, for sifting rock, etc.

By contacting the specialists of the "Grid 77" company by phone numbers listed on the website, you can obtain detailed information on the range of TsPVS STREK mesh, technical specifications and current price, and place an order for the supply of material.

Expanded metal mesh is not as popular as, for example, similar meshes made of polymers and nylon. However, galvanized mesh of the “TsPVS” and “PVS” types is used for those types of work where its analogues are not suitable.

Galvanized metal expanded mesh is extremely durable and resistant to aggressive environment, and is also lightweight. Its use is possible from domestic conditions to serious industrial facilities, where it is necessary for use in large-scale construction work.

However, without having a certificate of what the galvanized mesh of the “TsPVS” and “PVS” types is made of and for what work it is used, it is not recommended to use it.

1 General information

Galvanized network of types “TsPVS” and “PVS” is, in fact, an ordinary metal sheet with cells, which is evenly cut and then stretched into diamond-shaped cells, 10 x 10 mm, 15 x 15 mm, etc., that look like the surface of a chessboard. Most popular types of this product are referred to as “CPVS” and “PVS”.

Regardless of the type, all expanded metal meshes are made from sheet cold-drawn material in accordance with GOST. Networks of the “CPVS” and “PVS” types are mainly used for industrial work and work in agriculture.

Expanded-extraction networks of the types “TsPVS” and “PVS” 10 x 10 mm, 15 x 15 mm, however, like the others, in accordance with GOST requirements, do not have welds.

It is due to this that their production ultimately achieves low weight. It is worth noting that the weight of this type of product, although small, does not in any way affect the strength of the product.

In general, it is important to understand that high weight does not always equal high strength, although this misconception exists among many inexperienced buyers.

In general, networks of this kind cannot weigh much, since the plaster and facade work requires the use of the least weighty tools and materials in accordance with GOST requirements.

Open cells, as well as sharp edges of the product, are guaranteed provide a fairly high coefficient of friction, which is very important for situations where careful facade or plastering work is necessary.

Moreover, this property is also important in the production of reinforcement and similar work, where it is very important that the all-metal texture protects the mesh from unraveling. These are all the basic requirements of GOST, although many manufacturers ignore GOST regulations.

But in such cases, the product is not durable and has terrible characteristics, ultimately leading to the need to quickly replace the material used. But this is not always possible. Therefore, before purchasing such products, you should always familiarize yourself with their compliance with GOST requirements.

Considering that these products are made by cutting and drawing, after production work no waste remains, therefore, the final buyer pays only for the purchased product, without overpaying for unnecessary waste that could arise during production.

1.1 Areas of application

Let us also turn to the specific scope of application of this type of mesh. It is very important to understand what these materials are used for and what their strengths are. Expanded metal networks are used in the following areas:

- if it is necessary to apply plaster for reinforcement or perform plastering work in general;

- for sifting small rocks;

- for the production of flooring or steps of flight stairs;

- for fencing windows in apartments, balconies, heating radiators and so on;

- for creating fences for garden or yard areas (10 x 10 mm, 15 x 15 mm);

- when installing ventilation ducts;

- when creating enclosures for small animals.

To summarize, we can add that this galvanized network is most often used for applying plaster and for construction work in general.

And although at the moment polymer networks (PP) are most often used for plaster for reinforcement, it is safe to say that in certain situations they are completely replaced by the expanded metal type of such products.

2 Technology of use in construction work

As mentioned above, grids of this type can be used in different situations. Starting from the arrangement of portable platforms (the ribbed structure perfectly contributes to the adhesion of shoe soles and the plane of the platform itself, It is impossible to slip on the exhaust nets) and ending with traditional plastering work.

In fact, it is for plastering or general finishing work that it is purchased in the vast majority of cases. These meshes are also used to sift sand or dry mixtures. Sometimes there is an urgent need to perform such work. For example, if due to carelessness the putty or plaster becomes damp.

To avoid throwing away the entire bag, builders resort to sifting the composition. Of the available means, only expanded metal mesh will help accomplish this task.

Let us immediately note that small cross-section exhaust nets are used at construction sites. In fact, they can be confused with aluminum scraps, these materials are so soft and thin.

This is necessary in order to be able to reinforce plaster or putty, without weighing down the solution itself.

Stages of work:

- Cut out a piece of mesh of the required size.

- We stretch or compress it a little to obtain cells with the desired dimensions.

- Apply the first safety layer of mortar.

- We lay out the mesh; you can additionally secure it with hooks.

- We drown the mesh into the solution using a spatula or trowel.

- Apply subsequent layers.

The arrangement of screeds follows a similar algorithm. Although for screeds there are exhaust metal mesh They almost don’t buy. In this case, they are replaced by polymer (PP) products, which, other things being equal, are cheaper and, very importantly, extremely durable.

2.1 Production of expanded metal mesh (video)